Process for hydrogen blowing deoxidation of molten steel

A technology of liquid steel and process, which is applied in the process field of hydrogen blowing and deoxidation of molten steel, which can solve the problems of molten steel pollution and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

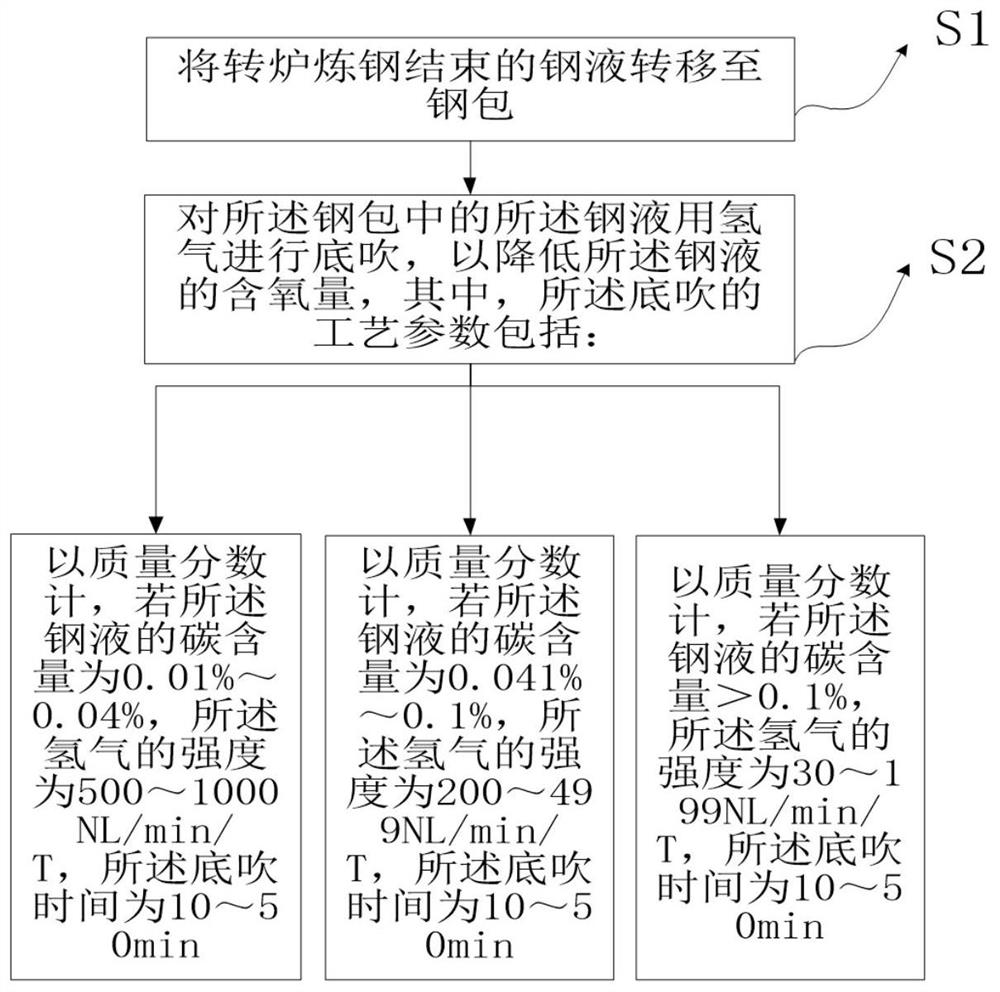

Method used

Image

Examples

Embodiment 1

[0049]200 tons of converter smelting Q345B steel, the mass fraction of carbon in molten steel at the end of smelting is 0.09%, after the converter is tapped to the ladle, hydrogen gas is blown into the bottom blower for a total of 20 minutes, and the hydrogen gas intensity is 226NL / min / T . After the deoxidation is completed, the dissolved oxygen content of molten steel is 15ppm.

Embodiment 2

[0051] P20 steel is smelted in a 200-ton converter, and the mass fraction of carbon at the end of the smelting process is 0.2%. After the converter is tapped to the ladle, hydrogen is blown into the bottom blower for a total of 15 minutes, and the hydrogen blowing intensity is 78.6NL / min / T. After the deoxidation is completed, the dissolved oxygen content of molten steel is 13ppm.

Embodiment 3

[0053] A 200-ton converter smelts M3A31 steel. The mass fraction of carbon at the smelting end point is 0.02%. After the converter is tapped to the ladle, hydrogen is blown into the bottom blower for a total of 30 minutes. The hydrogen blowing intensity is 783NL / min / T. After the deoxidation is completed, the dissolved oxygen content of molten steel is 19ppm.

[0054] In this application, the molten steel that has been deoxidized by bottom blowing hydrogen is subjected to subsequent processes, which avoids the contamination of the molten steel by inclusions in the traditional deoxidizer, achieves the purpose of deoxidation, and makes the molten steel ultra-purified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com