Application of expandable particle, and interface cleaning agent

A technology of expanding particles and interfaces, which is applied in the field of expandable particles and interface cleaning agents, can solve the problems of oil-based mud displacement and scouring, poor mud cake permeability, surfactant viscosity increase, etc., to facilitate cement truck pumps Delivery, easy to mix evenly, and enhance the effect of scouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

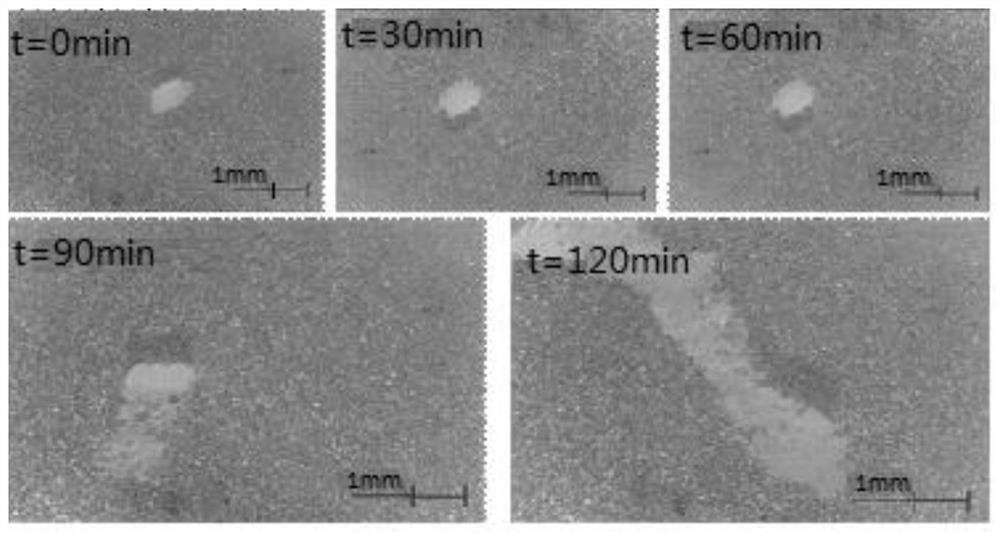

[0081] A paraffin wax with a melting temperature of 55-60°C is crushed into a 30-100 mesh powder by cryogenic freezing.

[0082] The hollow high elastic foam sponge is a polyurethane foam sponge.

[0083] Heat and melt the paraffin wax powder, coat and mix the uncompressed hollow high-elastic foam sponge and the paraffin wax solution evenly, each accounting for 50% by mass; cool the uniformly mixed material to 55-70°C, and compress to make a compressed For flakes, cool to room temperature.

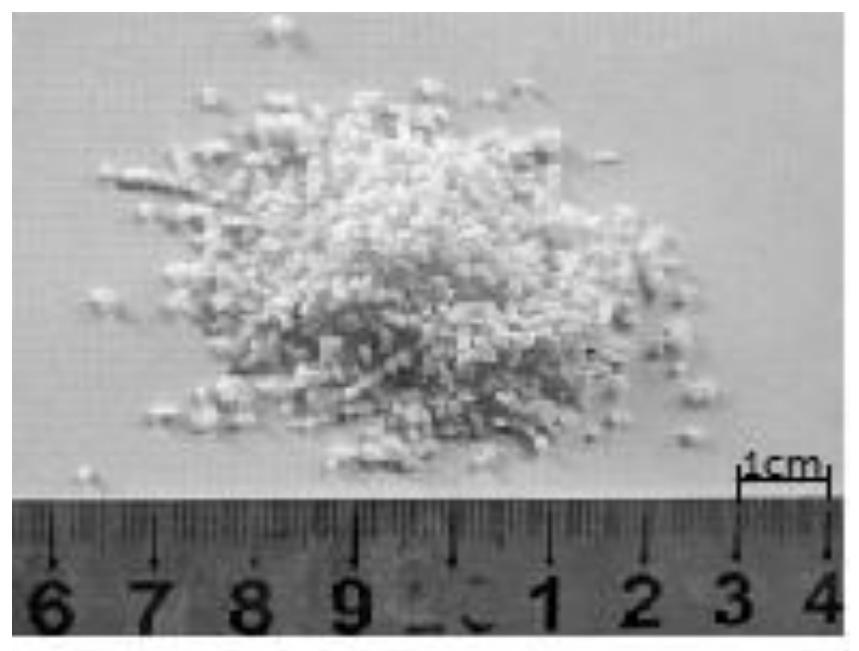

[0084] The compressed sheet is granulated with a cutting granulator to obtain the compressed expandable granules, and the size of the granulation is controlled to be less than 3mm in diameter and length, such as 0.5mm, 1mm, 2mm, 3mm, so that for mixing.

Embodiment 2

[0086] A polyurethane with a melting temperature of 65-70 DEG C is crushed into a powder of 100-200 meshes by cryogenic freezing.

[0087] The hollow high elastic foam sponge is a polyether foam sponge.

[0088] The polyurethane powder is heated and melted, and the uncompressed hollow high-elastic foam sponge and polyurethane hot melt are coated and mixed evenly. The hollow high-elastic foam sponge and polyurethane powder account for 80% and 20% by mass respectively; Cool to 65-80°C, compress to make a compressed sheet, and cool to room temperature.

[0089] The compressed sheet is granulated with a cutting granulator to obtain the compressed expandable granules, and the size of the granulation is controlled to be less than 3mm in diameter and length, such as 0.5mm, 1mm, 2mm, 3mm, so that for mixing.

Embodiment 3

[0091] The ethylene-vinyl acetate copolymer with a melting temperature of 65-70°C is crushed into 100-300 meshes by cryogenic freezing.

[0092] The hollow high elastic foam sponge is a rubber foam sponge.

[0093] The ethylene-vinyl acetate powder is heated and melted, and the uncompressed hollow high-elastic foam sponge and the ethylene-vinyl acetate hot melt solution are coated and mixed evenly. The hollow high-elastic foam sponge and the ethylene-vinyl acetate powder account for 20% and 80%; the uniformly mixed material is cooled to 65-80° C., compressed to make a compressed sheet, and cooled to room temperature.

[0094] The compressed sheet is granulated with a cutting granulator to obtain the compressed expandable granules, and the size of the granulation is controlled to be less than 3mm in diameter and length, such as 0.5mm, 1mm, 2mm, 3mm, so that for mixing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com