Coating production material transfer equipment with good protection effect

A paint and equipment technology, applied in the field of paint production material transfer equipment, can solve the problems of water ingress and rollover, lack of protective effect, low efficiency, etc., achieve good sealing and improve the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

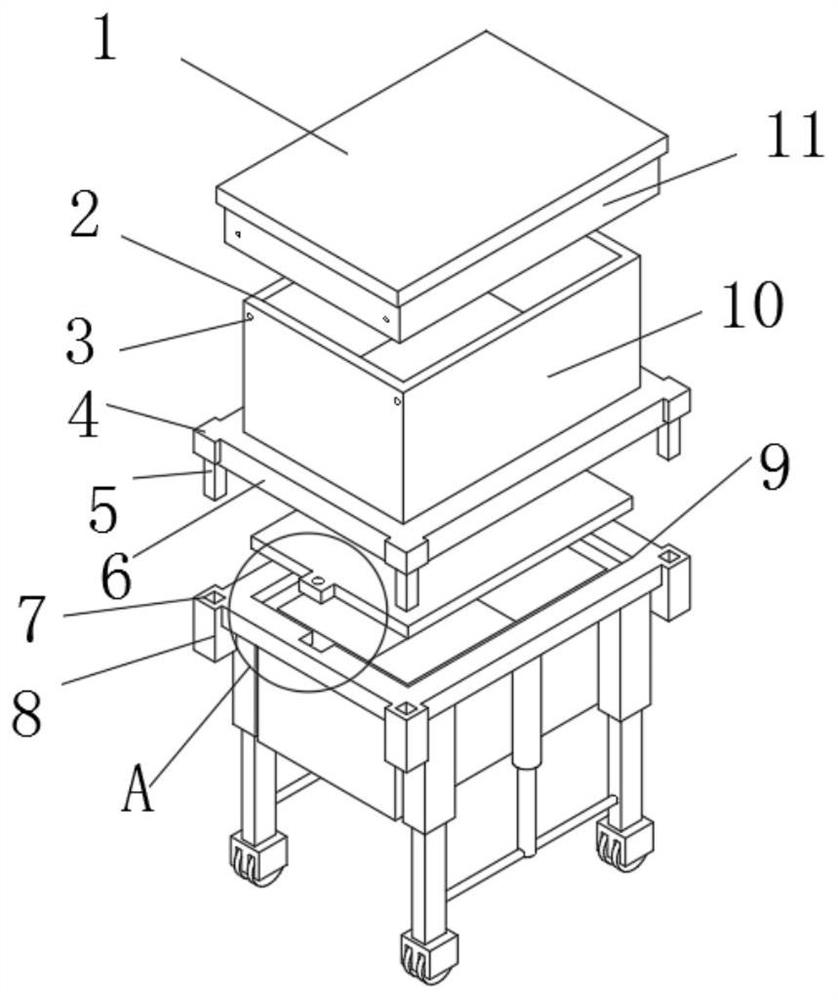

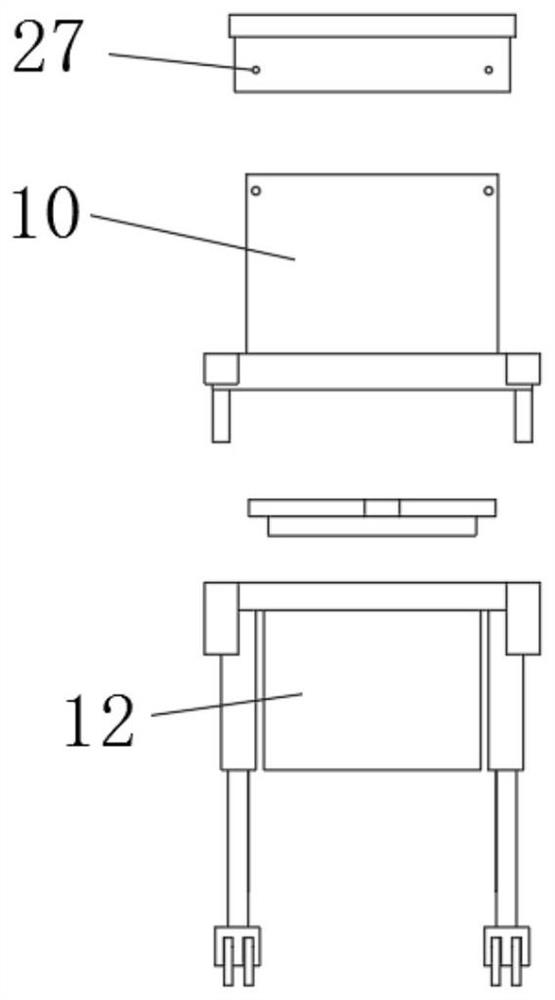

[0036]The following is a method of using the paint production material transfer equipment with good protective effect: the emulsion-like raw material is loaded in the liquid transfer box 12, and during installation, the moisture-proof asbestos board 18 is installed in the fitting groove 21, and then used The plug-in column 5 connects the liquid transfer box 12 and the powder material transfer box 10. The two-layer separated transfer structure does not need to be transferred in batches, and the two transfer devices have better sealing performance and have a moisture-proof effect, which can improve the protection of raw materials. The protective effect during transfer, in the actual transfer process, if the transportation ground is relatively uneven, the hydraulic column 26 can be activated to lift the transfer equipment to prevent the situation of dumping and rollover due to obstacles on the ground. The model of the hydraulic column 26 used therein is DW45-300.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com