Ship construction method, device and system

A construction method and ship technology, applied in the direction of ship construction, ship design, ship parts, etc., can solve the problems of ship type development, system reconstruction and transformation without considering, and achieve the effect of strong feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

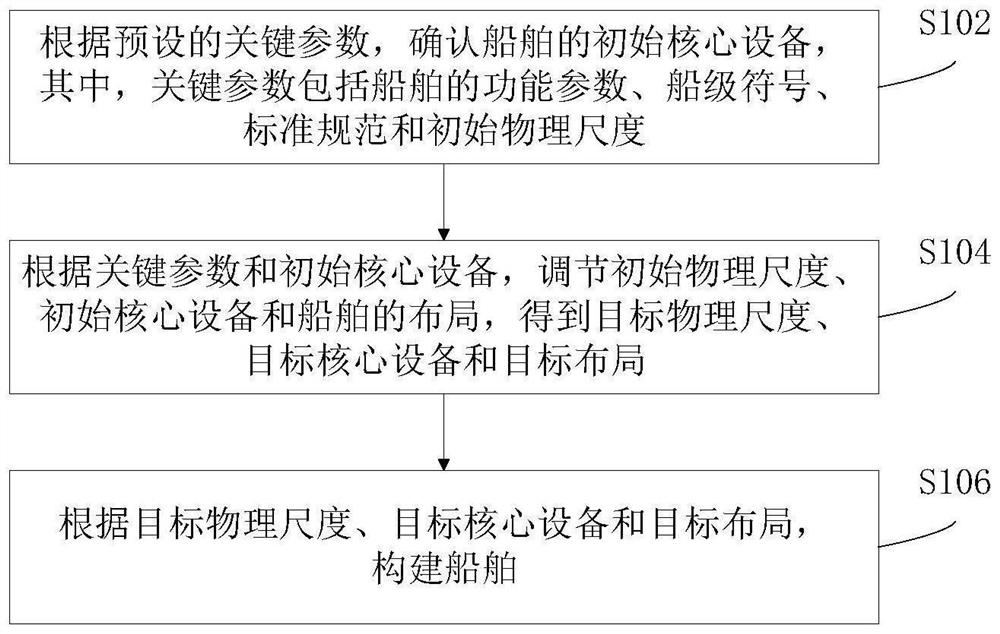

[0031] This embodiment introduces a construction method of a ship, such as figure 1 As shown, the method includes:

[0032] Step S102, confirming the initial core equipment of the ship according to the preset key parameters, wherein the key parameters include the ship's functional parameters, class symbols, standard specifications and initial physical dimensions.

[0033] Specifically, the aforementioned ships refer to a new generation of autonomous container ships. Before building a ship, it is necessary to clarify the function and approximate physical scale of the ship to be built (such as the length, width, height, displacement, draft, etc.) of the ship, that is, first confirm the functional parameters and initial physical scale, according to the functional parameters. Confirm the class notation, the class notation corresponds to the corresponding standard specification, that is, the official standard specification on the class notation can be extracted according to the cl...

Embodiment 2

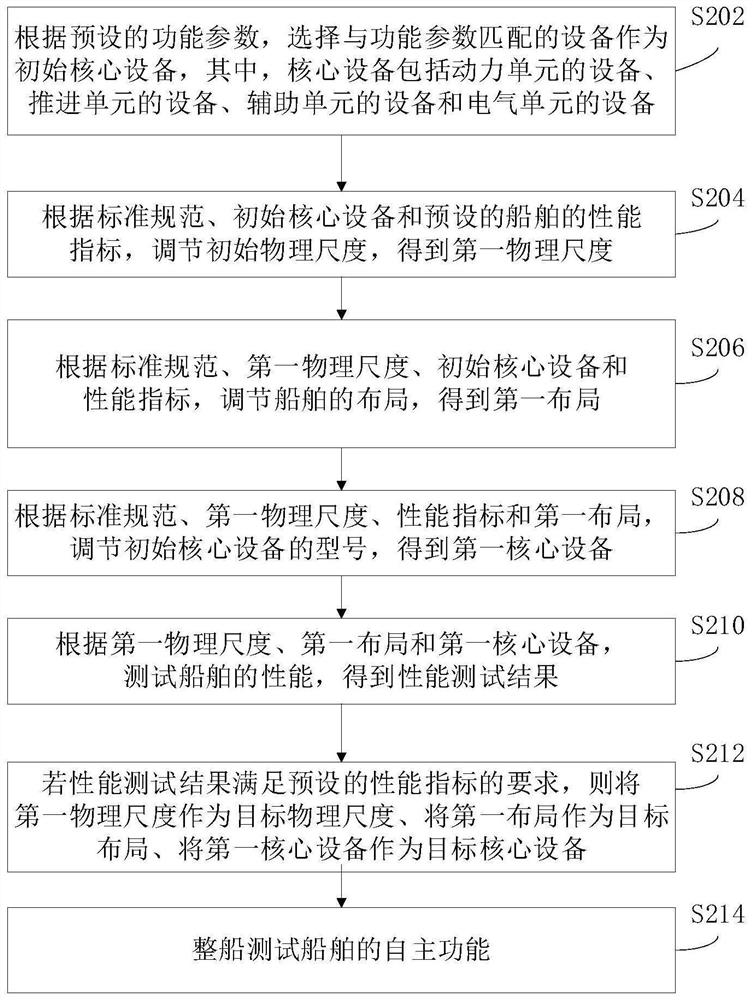

[0041] The embodiment of the present invention provides another ship construction method, such as figure 2 As shown, the method includes:

[0042] Step S202, according to the preset functional parameters, select the equipment matching the functional parameters as the initial core equipment, wherein the core equipment includes power unit equipment, propulsion unit equipment, auxiliary unit equipment and electrical unit equipment.

[0043] Specifically, the above functional parameters can reflect the autonomous functions of the ship. If the requirements for autonomous functions are relatively high, select core equipment with a high degree of intelligence; core equipment includes equipment in multiple units, specifically, anchors in the outer outfitting. The basic model of the machine, the basic model of the driving machine of the power system (also called the power unit), the basic model of the propeller in the propulsion system (also called the propulsion unit), the basic mode...

Embodiment 3

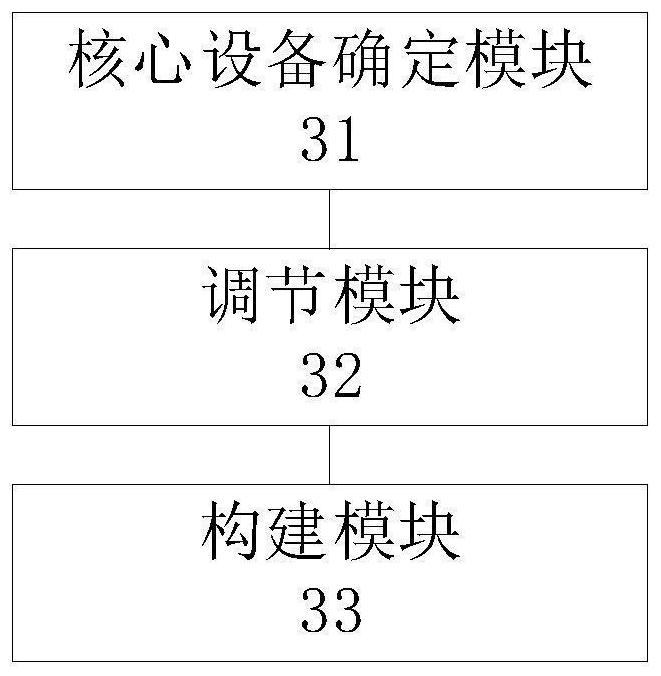

[0071] An embodiment of the present invention provides a construction device for a ship, such as image 3 As shown, the device includes:

[0072] The core equipment determination module 31 is configured to confirm the initial core equipment of the ship according to the preset key parameters, wherein the key parameters include the ship's functional parameters, ship classification symbols, standard specifications and initial physical dimensions.

[0073] The adjustment module 32 is configured to adjust the initial physical scale, initial core equipment and ship layout according to key parameters and initial core equipment, to obtain target physical scale, target core equipment and target layout.

[0074] The construction module 33 is used to construct the ship according to the target physical scale, target core equipment and target layout.

[0075] The ship construction device provided by the embodiment of the present invention has the same realization principle and technical eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com