Flexible cable breaking force testing device and method

A testing device and breaking force technology, applied to measuring devices, applying stable tension/pressure to test material strength, instruments, etc., can solve problems such as long inspection time, high inspection cost, and increased burden on enterprises, and achieve The overall structure is simple and the effect is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

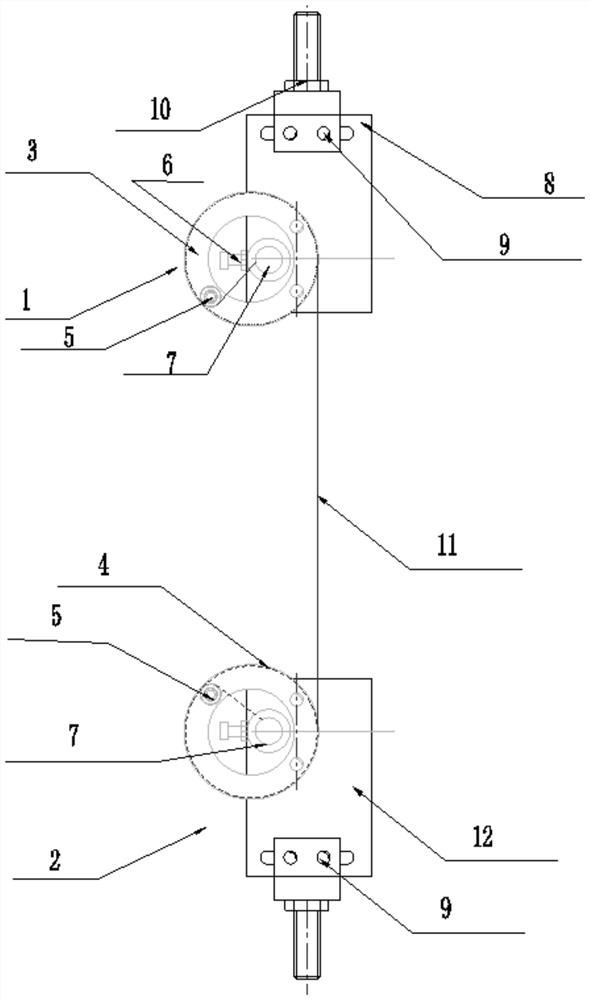

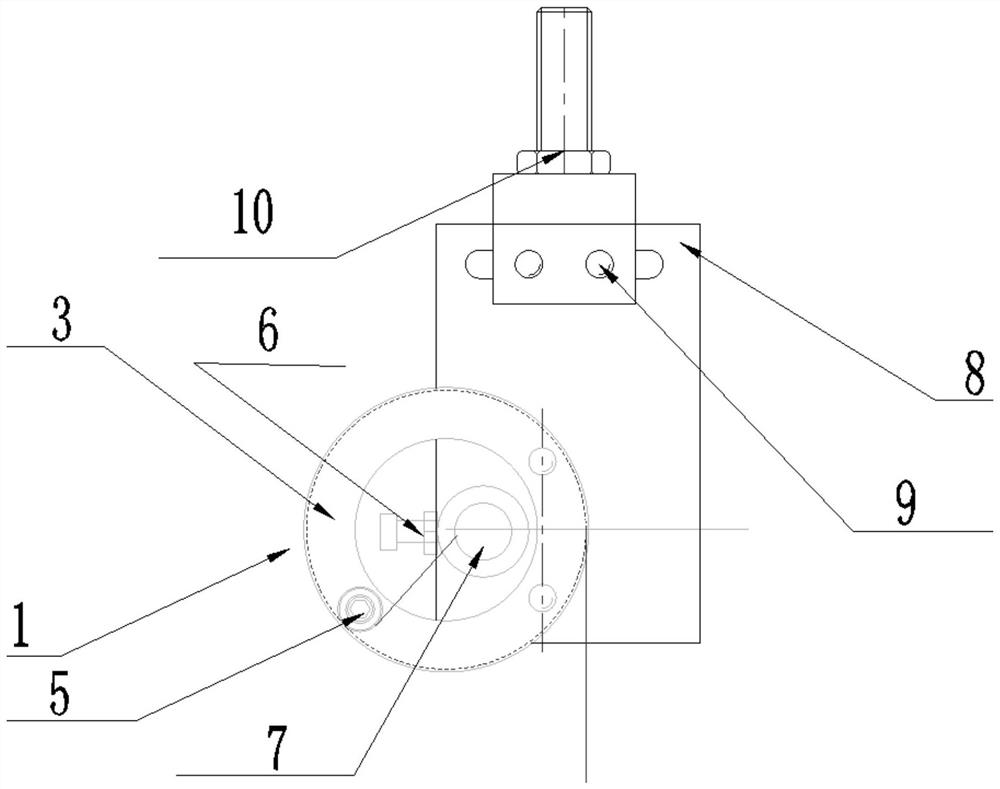

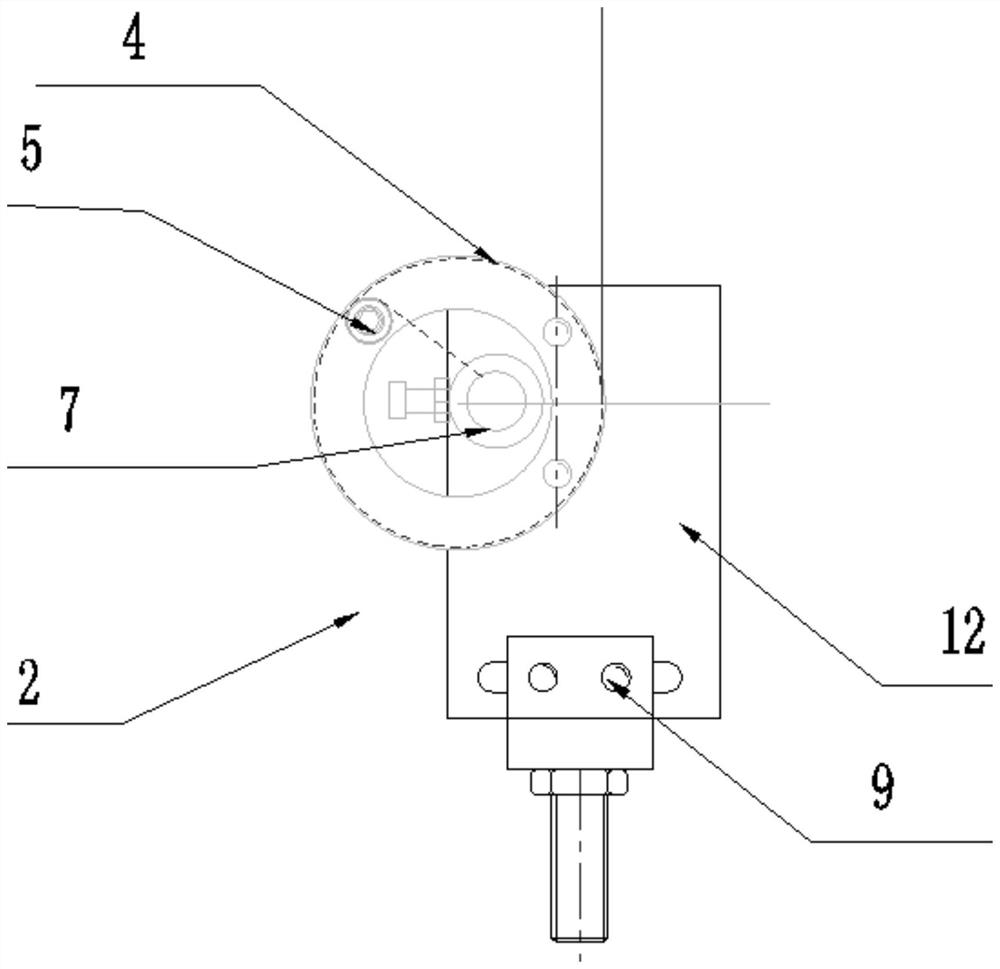

[0032] Such as Figure 1-3 As shown, a flexible cable breaking force test device includes an upper fixture 1 and a lower fixture 2 arranged face to face, the distance between the upper fixture 1 and the lower fixture 2 is adjustable, and the upper fixture 1 and the lower fixture 2 are respectively The two ends of the flexible cable 11 to be tested for breaking force are fixedly installed, and the flexible cable 11 to be tested for breaking force between the upper clamp 1 and the lower clamp 2 is placed vertically. The diameter of the flexible cable 11 for testing the breaking force is The upper clamp 1 and the lower clamp 2 are connected to the driving mechanism. The driving mechanism is a tension machine with a tension sensor and a control panel. The flexible cable 11 to be tested for breaking force is broken and analyzed for breaking force. The displacement distance of the flexible cable 11 to be tested for breaking force is 1-800mm, the pulling force range is 0.1-50kN, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com