Double-drive speed regulation rotary table of numerical control machine tool

A technology of CNC machine tools and turntables, which is applied in the direction of driving devices, metal processing machinery parts, metal processing equipment, etc., can solve the problems that cannot meet the requirements of low speed and high torque speed regulation at the same time, and achieve the effect of improving the quality of braking and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

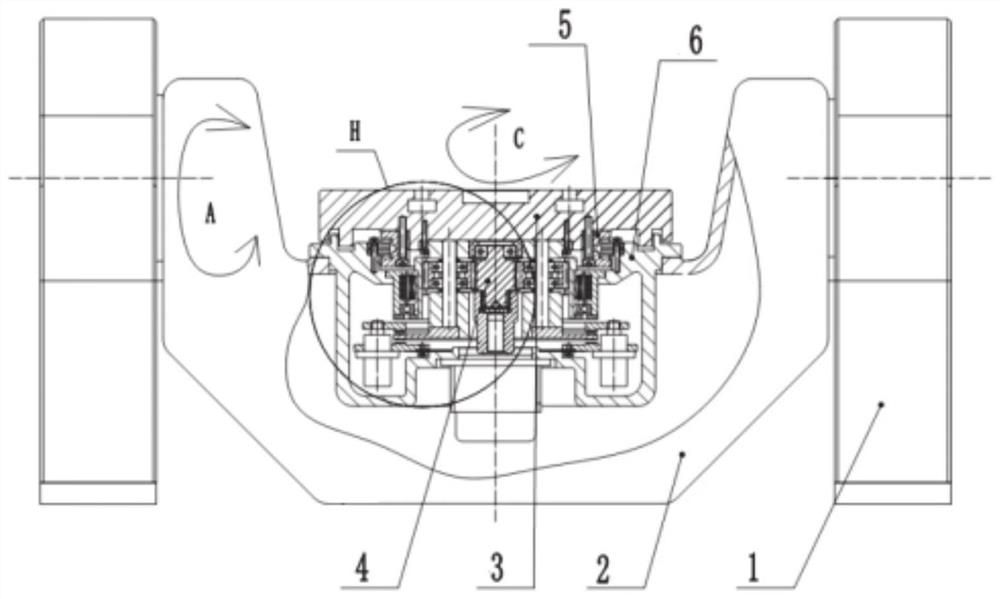

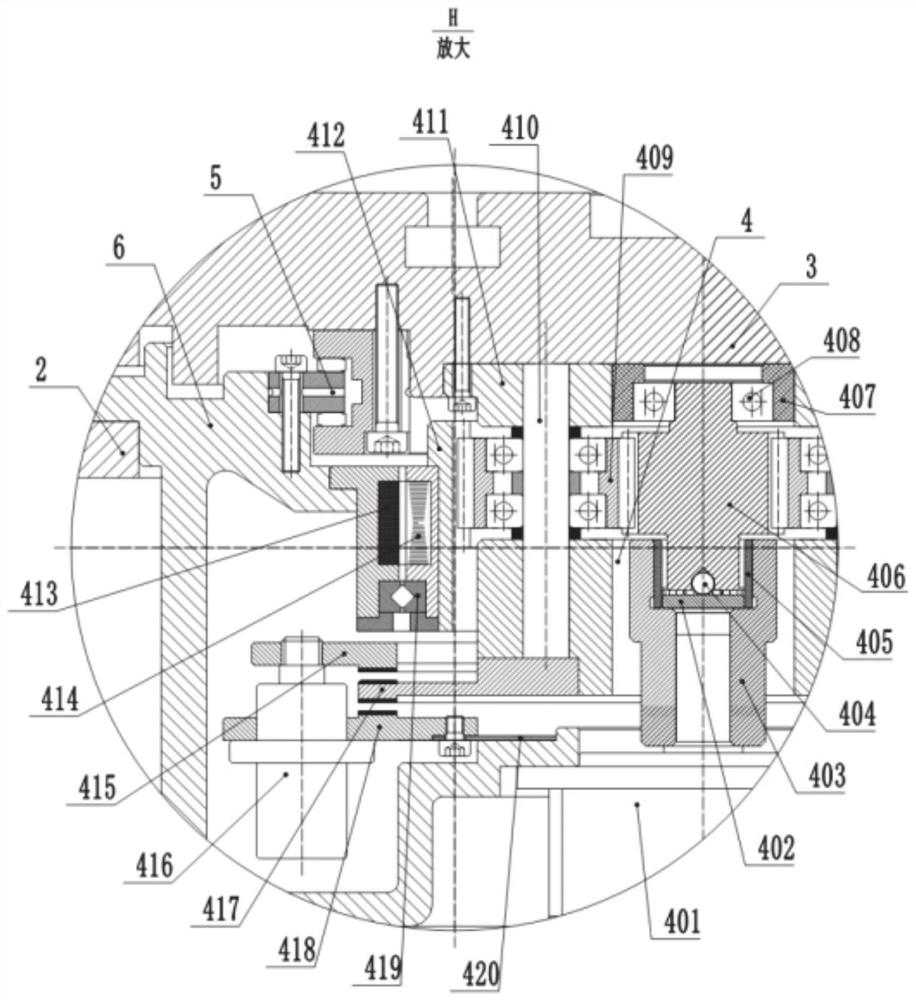

[0029] This embodiment provides a double-drive speed-regulating turntable for a CNC machine tool, such as figure 1 and figure 2 As shown, it includes a turntable seat 1, a turntable frame 2, a workbench 3, a speed regulating mechanism 4 and a table body 6, and the speed regulating mechanism 4 adopts dual driving force sources.

[0030] Both ends of the turntable frame 2 are rotatably connected with the turntable base 1 , and the turntable frame 2 can rotate around the A axis relative to the turntable base 1 , wherein the A axis is an axis perpendicular to the turntable base 1 . The table body 6 is fixed in the turntable frame 2, the top of the table body 6 has an opening, and the installation cavity of the speed regulating mechanism 4 is arranged inside;

[0031] In this embodiment, the table body 6 is connected to the table body 3 through the first bearing 5, the first bearing 5 is fixed at the opening of the table body 6, and the table body 3 can rotate relative to the tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com