Metal powder granularity screening device for selective laser melting forming

A technology of laser selective melting and metal powder, which is applied in the fields of filtration and sieving, solid separation, chemical instruments and methods, etc. It can solve the problems of ineffective powder particle size classification, fine powder easily clogging the screen, and low powder screening efficiency. , to achieve the effect of ensuring stability, preventing stagnation, and reducing the probability of blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

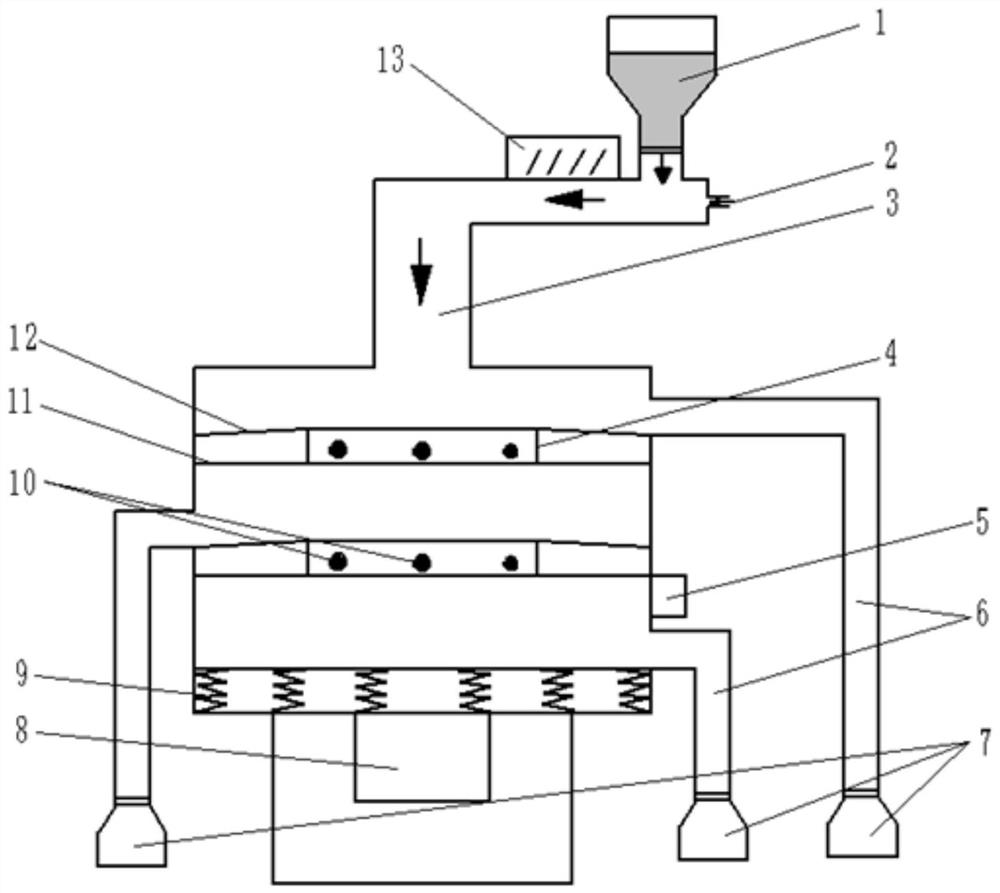

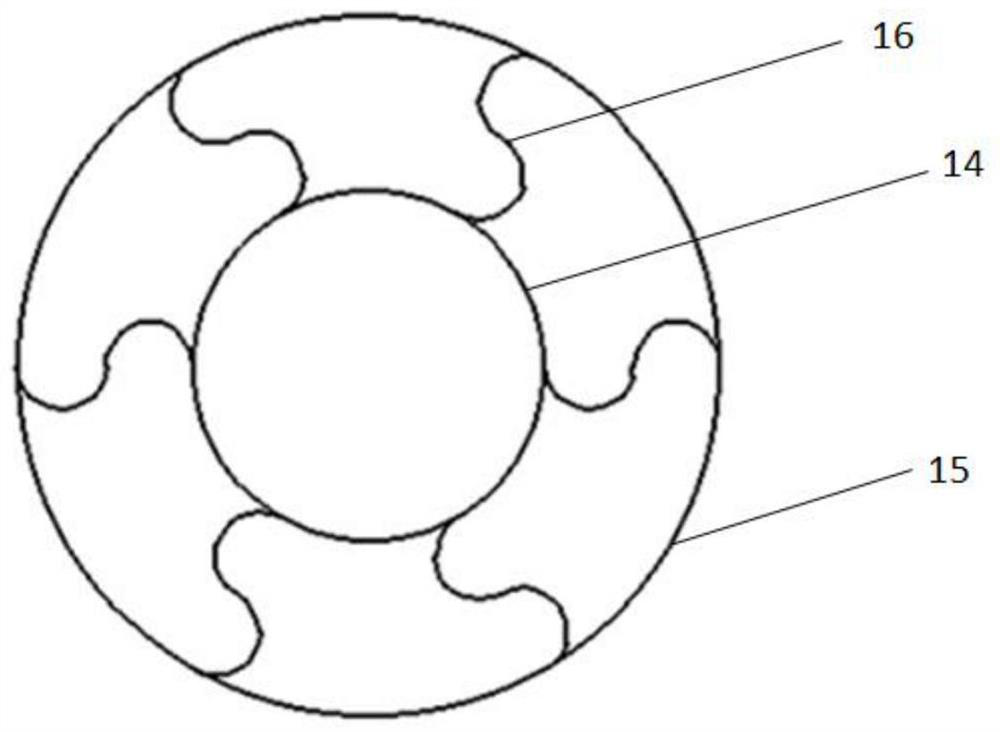

[0026] Such as figure 1 As shown, the vibrating screen body of the device includes a feeding mechanism and a screening mechanism. The outer wall of the feeding mechanism is installed above the outer wall of the screening mechanism. One layer of screening bottom curtain 11 is set, and vibrating balls 10 are arranged between each layer of screen mesh 12 and the screening bottom curtain 11 arranged below it, and ultrasonic transducer 5 is installed on the outer wall of the screening mechanism, ultrasonic transducer 5 It is on the same plane as the screen cloth 12 located below. In this way, the device of the present invention is provided with two layers of screens 12 with different diameters, so that the target metal powder can be screened out at one time, and the powder screening efficiency can be improved. And by introducing the ultrasonic converter 5 in the fine powder screen layer, it solves the situation that the fine powder is easy to block the screen due to the presence o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com