Large-scale deep-sea fixed type anti-stormy-wave breeding platform

A fixed, anti-wind and wave technology, applied in fish farming, application, climate change adaptation, etc., can solve problems such as poor economy and redundant structure of farming platforms, so as to reduce platform manufacturing costs, reduce damage to farmed fish, and economical good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS

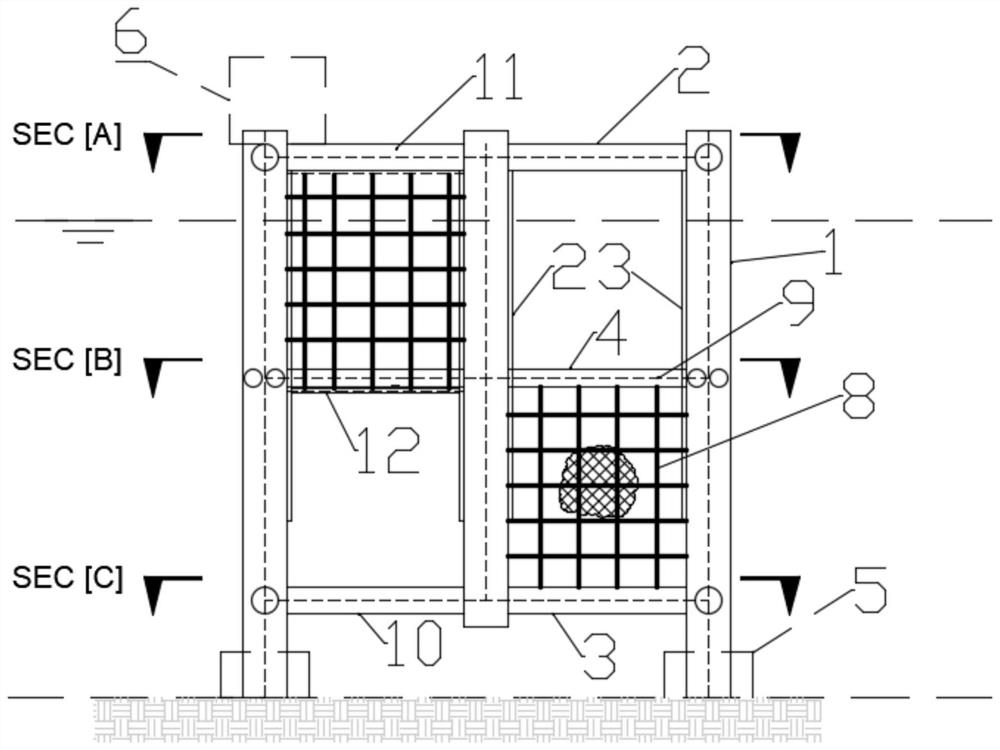

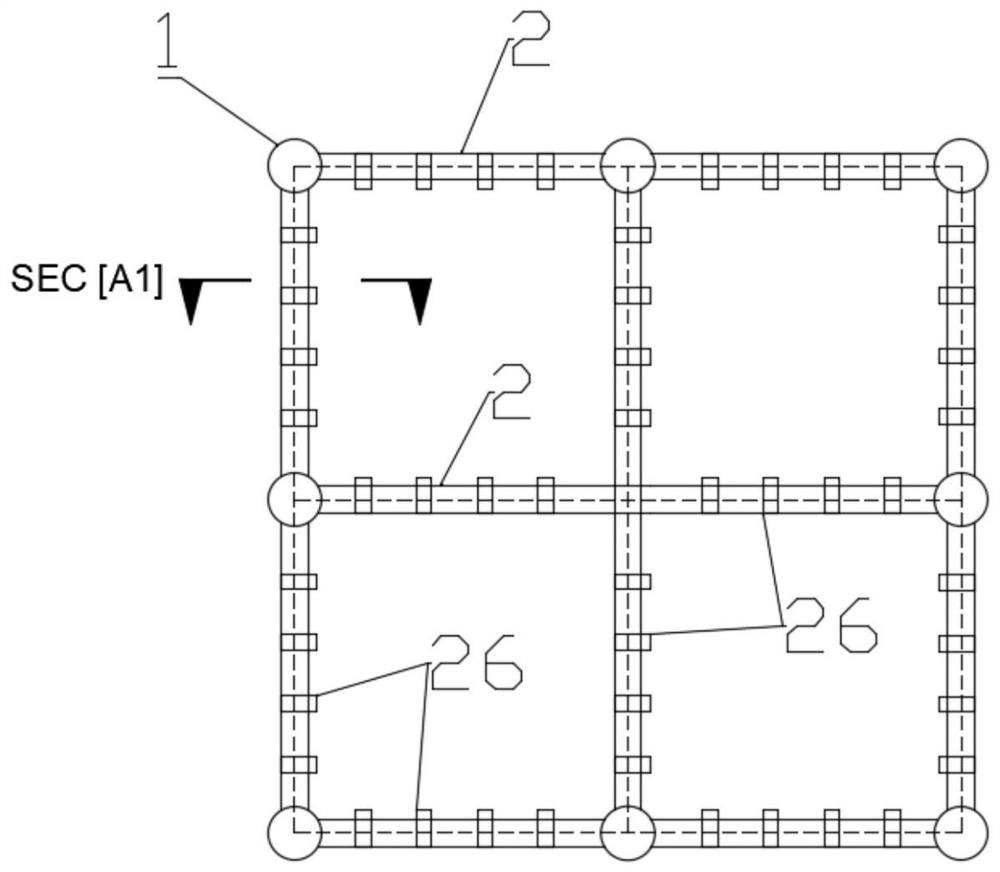

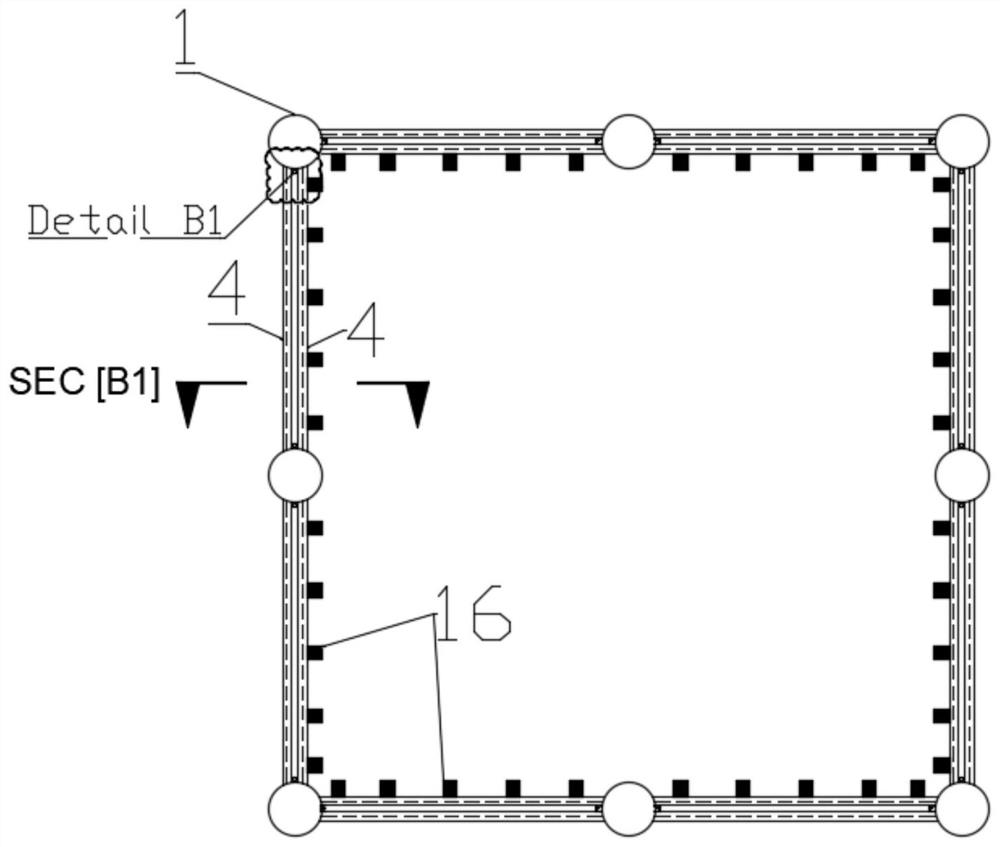

[0048] like Figures 1 to 14 As shown, the present invention has a deep-far-sea fixed anti-wind blades platform structure, divided into platform main frame, bottom sitting connection structure, a web, a web, and a platform frame connecting member and a web lifting system.

[0049] The platform main frame includes a vertical tube structure 1, a top horizontal tube structure 2, a bottom horizontal tube structure 3, and an intermediate double drain structure 4. Platform jobs have an average water 30m, the maximum wave is 10 meters, and the middle-level double-drain structure 4 is highly based on the large wave high and water depth of the water depth of the water depth of the sea. It is 22 meters from the sea. The bottom of the platform main frame is sitting on the bottom connection structure 5. According to the subsea geological conditions, the marine environment conditions and platform network box breeding scale can be used a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com