Automatic charging pile for mining walking trolley

A walking car, automatic charging technology, applied in electric vehicle charging technology, charging stations, circuits, etc., can solve the problem of high pressure on the driving structure, and achieve the effects of rapid charging, improved stability, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

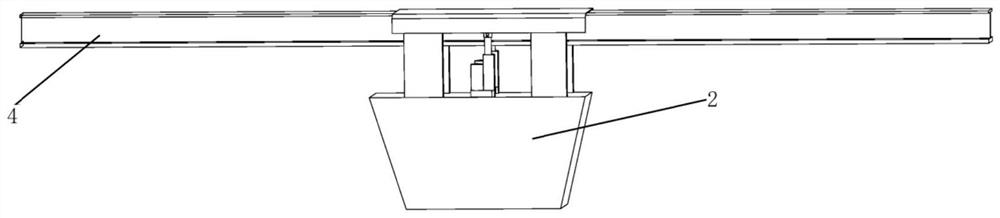

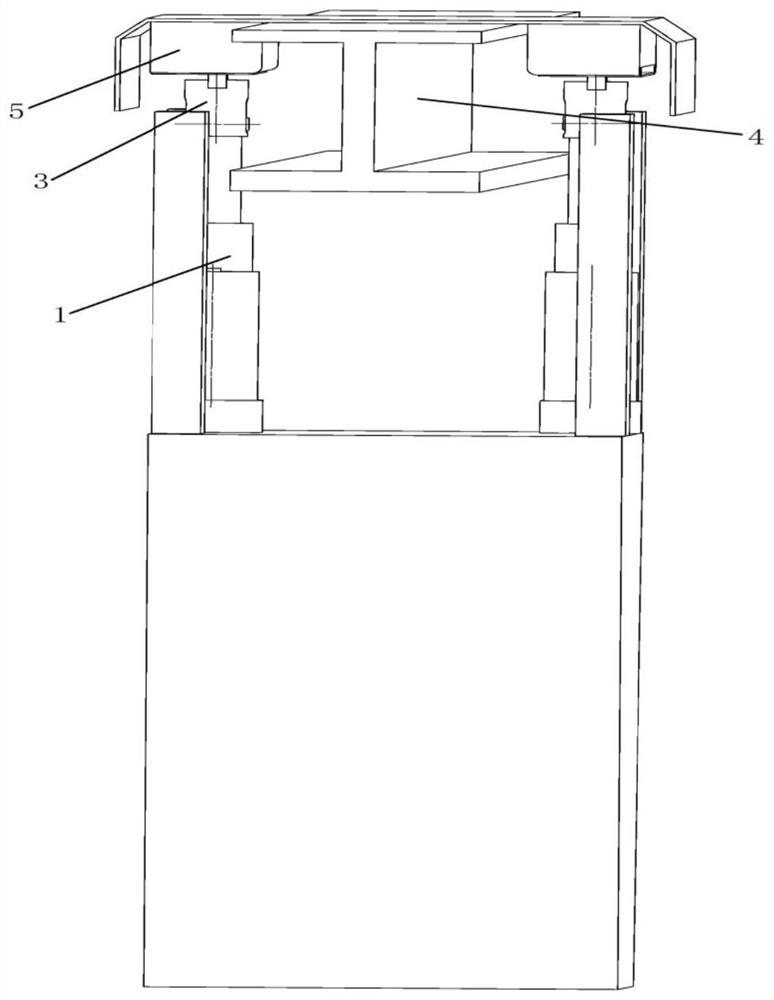

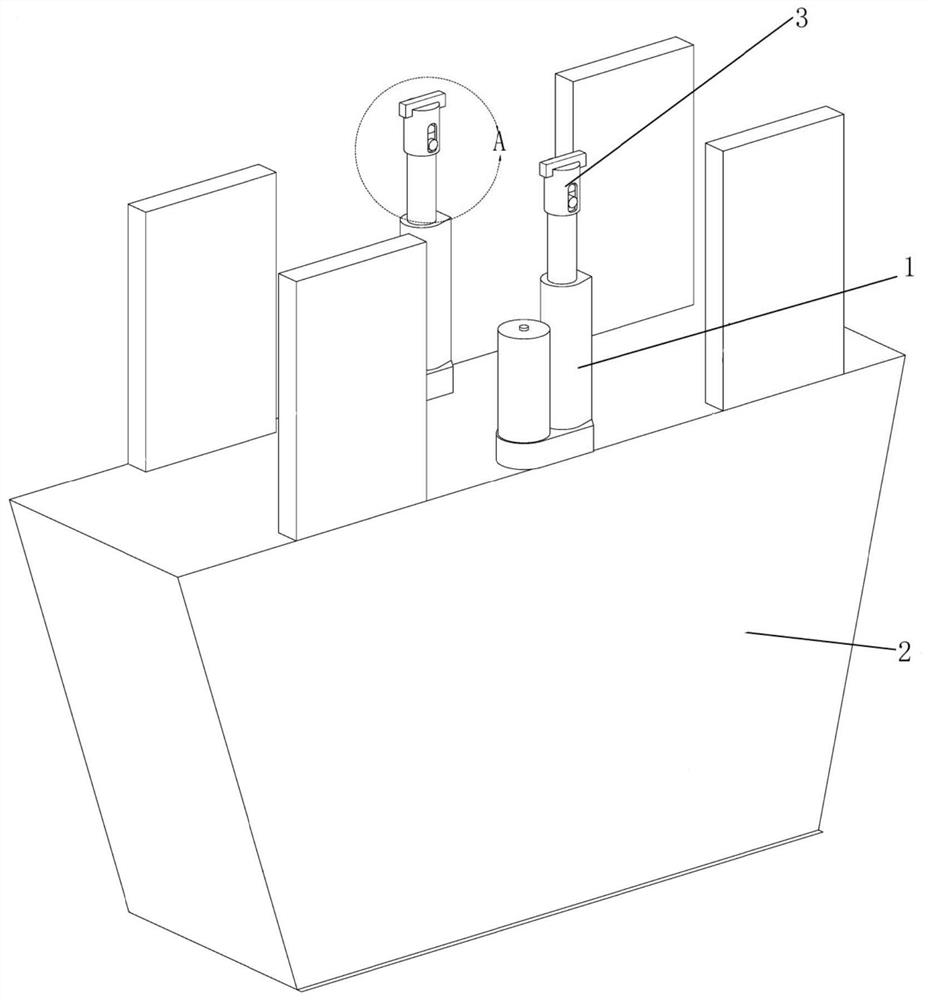

[0029] The invention discloses an automatic charging pile for mining walking trolley, referring to figure 1 , 2 , including an electric push rod 1 installed on the upper part of the traveling trolley 2, a male contact 3 and a plurality of contact females 5 installed under the traveling track 4, the traveling trolley 2 is hung below the traveling track 4, and the electric push rod 1 The male contact 3 is driven close to or away from the female contact 5 .

[0030] refer to image 3 , 4 , the contact male 3 includes a male contact block 6, a telescopic part 7 and an insulating layer 8, the male contact block 6 is connected to the insulating layer 8, the telescopic part 7 is connected to the inside of the insulating layer 8, and one end of the telescopic part 7 is connected to the male The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com