Red color blindness correction lens and preparation method thereof

A technology of color blindness and lenses, applied in the field of ophthalmology, can solve the problems of unacceptable appearance of big red and big blue, vision loss, inability to distinguish, etc., achieve good rigidity, increase brightness, and sensitive spectral response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: Preparation of organic / inorganic nanocomposite microspheres and color vision correction lenses

[0057] (1) Preparation of organic / inorganic nanocomposite microspheres:

[0058] a. Take 2.4g of emulsifier sodium dodecylbenzenesulfonate and add it to 1000g of pure water. After it is completely dissolved, add 30g of nano-cobalt oxide, add 140g of sodium acetate saturated aqueous solution dropwise within 70min, and then add the crosslinking agent butyl acrylate 20g; feed nitrogen into the reaction kettle, add 145g of dichloromethane solvent containing spiropyran compound (formula I) (105g of spiropyran 40g solvent), add 28g of methyl acrylate monomer, stir and heat up to 65°C, add Initiator sodium persulfate 0.1g, keep warm for 16h, filter, wash and dry to obtain acrylate / spiropyran / cobalt oxide nanospheres. The yield was 80%.

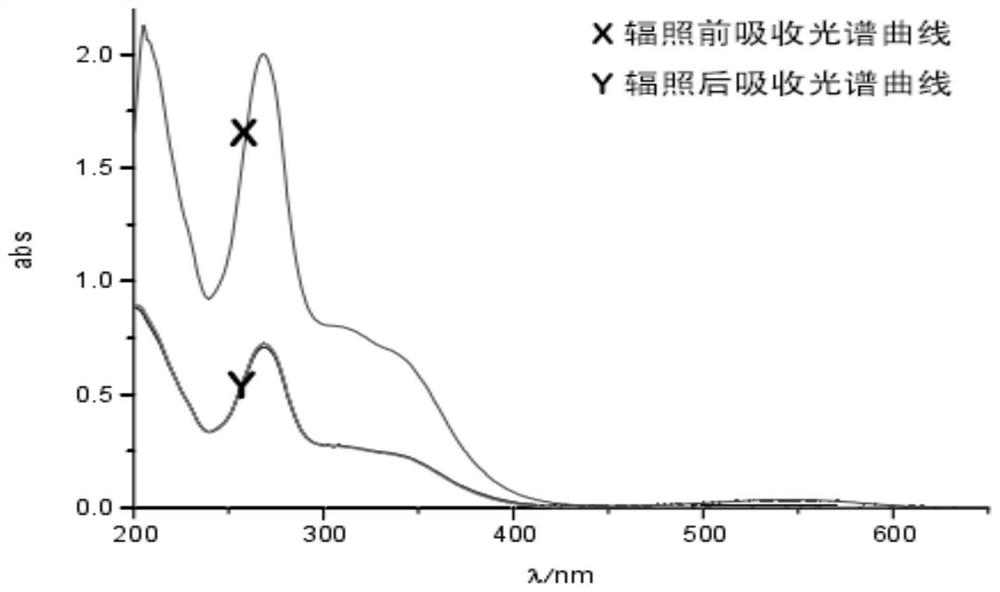

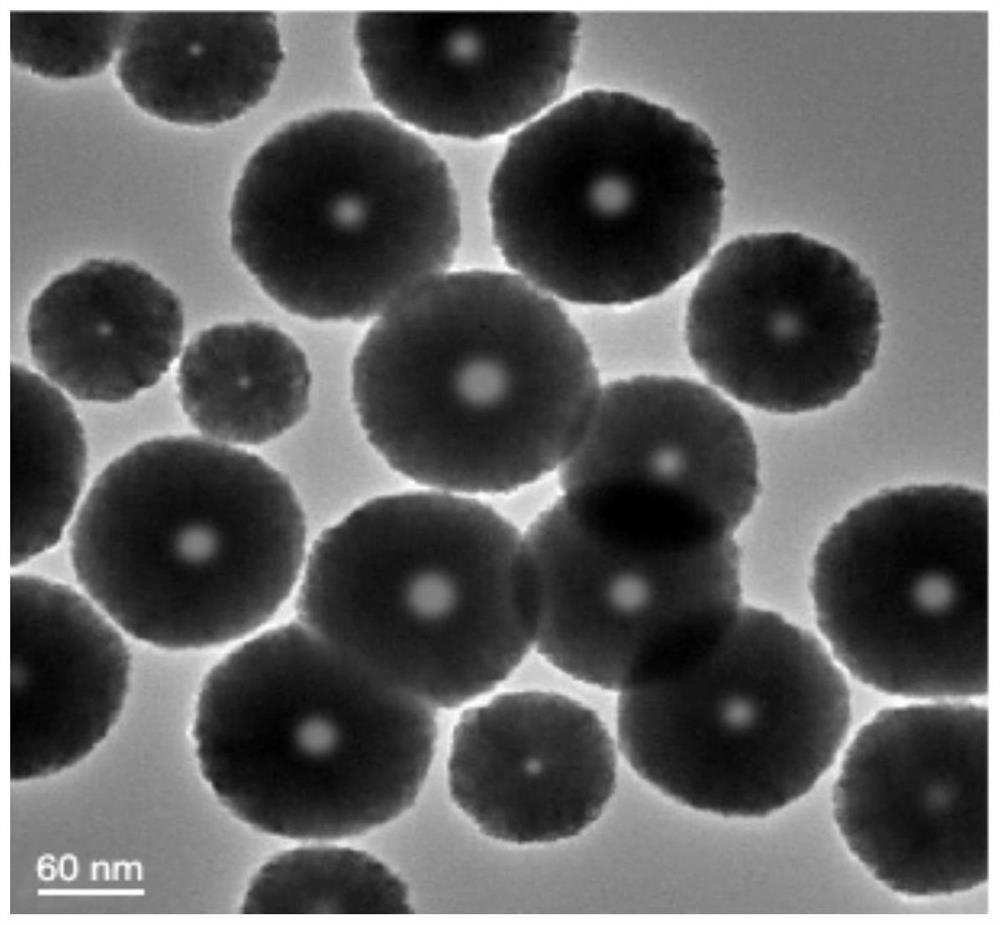

[0059] b. the product prepared in step a is observed through a transmission electron microscope, such as figure 2 As shown, it c...

Embodiment 2

[0065] Embodiment 2: Preparation of organic / inorganic nanocomposite microspheres and color vision correction lenses

[0066] (1) Preparation of organic / inorganic nanocomposite microspheres:

[0067]i. Take 2g of emulsifier sodium dodecylbenzene sulfonate and add it to 1000g of pure water. After it is completely dissolved, add 26g of nano-titanium oxide, add 140g of sodium acetate saturated aqueous solution dropwise within 70min, and then add 20g of crosslinking agent butyl acrylate ; Feed nitrogen into the reactor, add 130 g of dichloromethane solvent containing spiropyran compound (formula I) (100 g of spiropyran 30 g solvent), add 26 g of ethyl acrylate monomer, stir and heat up to 70 ° C, add trigger Add 0.1 g of sodium persulfate, keep warm for 16 hours, filter, wash, and dry to obtain acrylate / spiropyran / titanium oxide nanospheres. The yield was 78%.

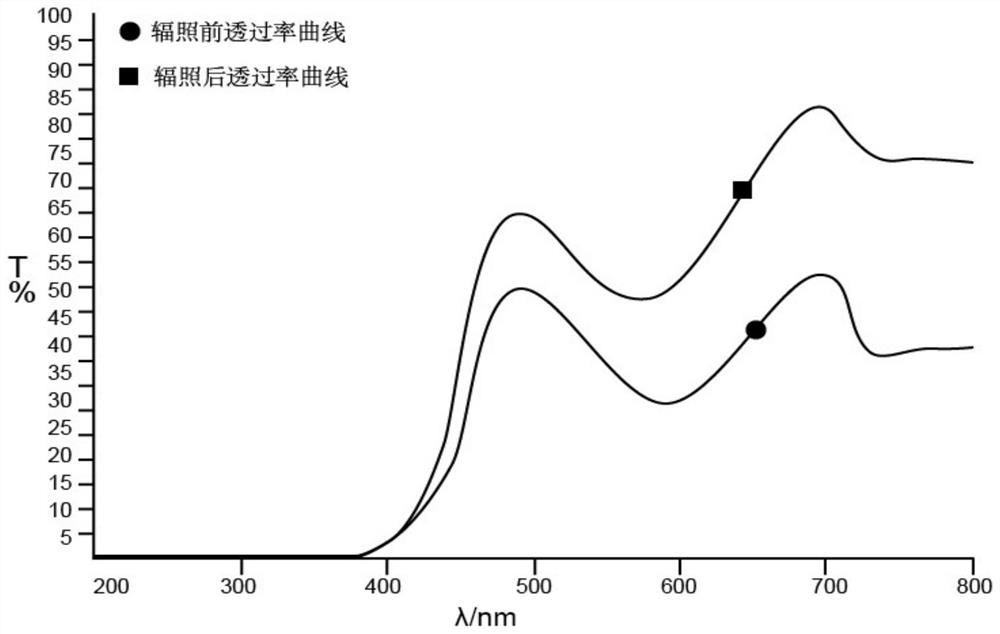

[0068] ii. the product prepared in step (i) is observed through a transmission electron microscope, such as Figure 4 ...

Embodiment 3

[0073] Embodiment 3: Analysis of the nanocomposite microsphere structure prepared in embodiment 1-2

[0074] Carry out N to the nanocomposite microsphere sample that embodiment 1-2 prepares 2 Adsorption-desorption isotherm detection was carried out to analyze the structural characteristics of the nano-microspheres, and the results are shown in Figure 5. Wherein P1, P2 represent the nanocomposite microsphere sample that embodiment 1,2 prepares respectively, Figure 5a for N 2 Adsorption-desorption isotherm, the isotherm type of the sample with 10h hydrothermal reaction time is type IV, at P / P 0 There is a hysteresis loop at 0.4-1.0, indicating the existence of mesopores. Figure 5b It is a pore size distribution curve. There is an obvious raised peak at 3nm, and there is no raised peak after 5nm, indicating that the pore size is small, and the pore size is about 3nm. The mesopores in the sample are formed by the aggregation of nanoparticles. All these results are consistent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com