A continuous detection method of cable burnt smell based on inspection robot

An inspection robot and cable technology, which is applied in the field of continuous detection of scorched odor of cables based on inspection robots, can solve the problems of poor robustness, inability to have a good division effect, and aggravate the difficulty of feature extraction, and reduce workload. Effect

Active Publication Date: 2022-04-12

NANJING TETRAELC ELECTRONICS TECH CO LTD

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] (1) Feature extraction is difficult: when there are too many types of odors, the classification and recognition results obtained by using traditional methods are often not ideal, that is, the features extracted by these common algorithms cannot truly represent the characteristics of material odor information

[0005] (2) Poor robustness of traditional methods and feature extraction: Traditional methods are mostly based on empirical rules, and cannot achieve good segmentation results when some gas components are similar, and the on-site interference environment will further aggravate the difficulty of feature extraction

For example, if the classification effect map is a five-point feature distribution map, it is based on static gas features. It cannot have a good extraction effect and feature description for continuously changing features, and if the changing gas is described by static features, its scope of application is relatively narrow. In the robot Problems cannot be found completely during inspection

[0006] (3) The feature description of ordinary deep learning methods is relatively static: while gas detection is continuous sampling in the air, which is approximately a continuous signal, the existing methods cannot describe the characteristics of gas changes from the time dimension, that is, continuous dynamic detection is not possible

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

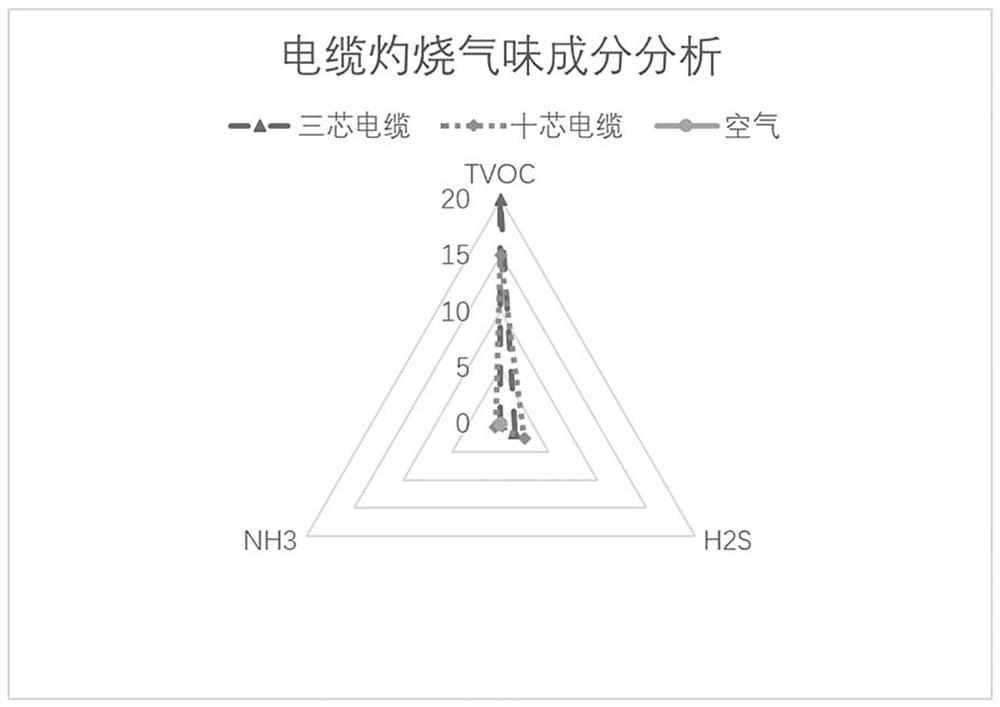

[0046] Two different cables are selected. In this example, two samples of three-core fireproof soft leather cable (hereinafter referred to as three-core) and ten-core fireproof hard cable (hereinafter referred to as ten-core) are selected as experimental materials. The appearance of the two cables, There is a noticeable difference in feel but the material is the same.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

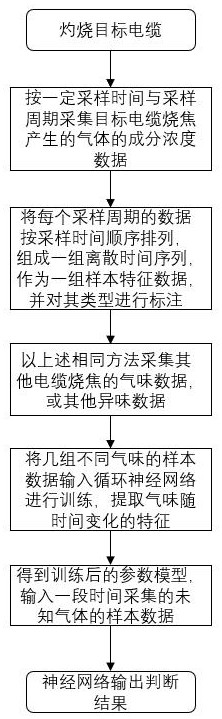

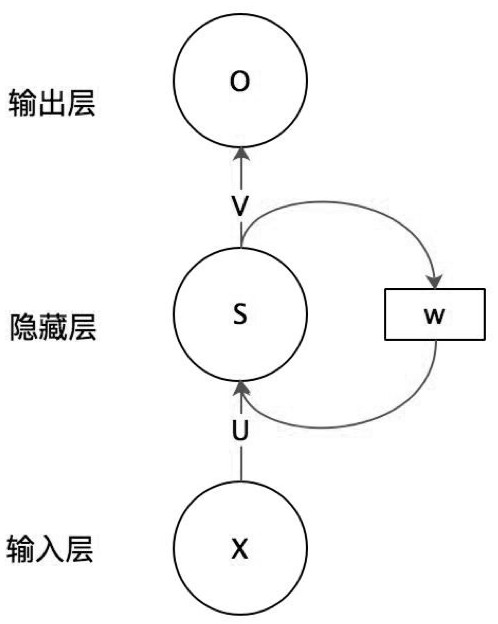

The invention discloses a method for continuously detecting cable burnt smell based on an inspection robot, which uses high temperature to burn different types of cables, and then a gas sensor module detects the gas generated by high-temperature burning of cables, collects corresponding smell data samples, and forms Discrete time series signal, and marked as the burning smell of the cable in the smell environment, the smell data is used as a sample to train through the cyclic neural network, that is, the smell concentration data is collected continuously, and the smell data is composed of a time series in chronological order Signal, as the input of the cyclic neural network, and then combined with mathematical algorithms to allow the cyclic neural network to self-fit to the information state that can highlight the changes in the characteristics of the detected gas over time. At this time, the concentration characteristics can be quickly extracted and classification decisions can be made after the gas data is input. , to realize the detection and classification of gases.

Description

technical field [0001] The invention belongs to the gas detection technology, in particular to a method for continuously detecting cable burnt smell based on an inspection robot. Background technique [0002] Cable burnt odor identification belongs to specific odor identification. At present, for odor data collection, most of them use sensitive membrane materials to absorb gas molecules to generate vibration, and what is sampled is a complex time series signal. This signal will be affected by various factors such as sensitive membrane material, gas type and concentration, and external environment (such as temperature and humidity). For the sampled data, manually designed features are usually used, combined with wavelet decomposition, support vector machine and other methods for identification; some improved algorithms independently design feature extraction and classification, and the process of feature extraction includes manual design features, wavelet decomposition and pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N33/00G06F30/27G06N3/08

CPCG01N33/0034G01N33/0067G06F30/27G06N3/08

Inventor 陈玖霖刘爽闵济海

Owner NANJING TETRAELC ELECTRONICS TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com