Fatigue crack initiation prediction method considering surface integrity

A technology for surface integrity and fatigue cracks, applied in measuring devices, force/torque/work measuring instruments, material analysis using radiation diffraction, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0156] In order to better illustrate the purpose and advantages of the present invention, the content of the invention will be further described below in conjunction with the accompanying drawings and examples.

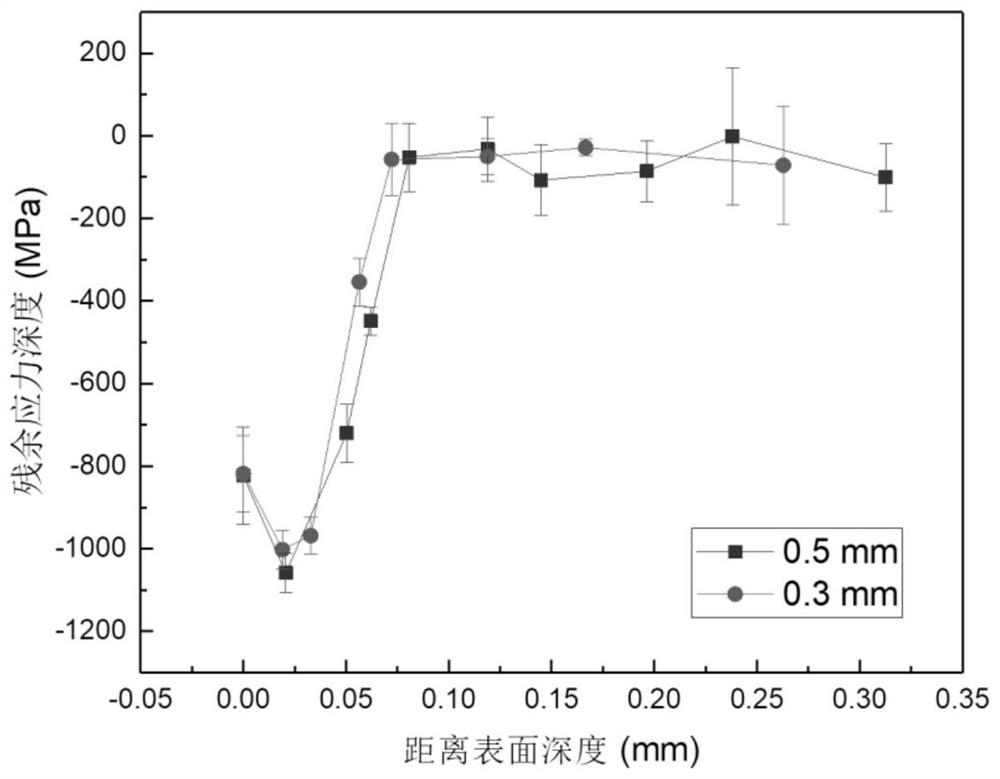

[0157] Such as figure 1 As shown, a fatigue crack initiation prediction method considering surface integrity disclosed in this embodiment is used to simulate and predict the initiation of tensile fatigue cracks in the shot-peened 45CrNiMoVA material, including the following steps:

[0158] Step 1. Obtain surface integrity parameters through experimental measurement, and the surface integrity parameters mainly include surface roughness, residual stress and surface layer microtexture.

[0159] Step 1.1. Measure the surface roughness through experiments, and use the maximum height R of the profile z and the average width of contour elements R sm Characterize surface roughness.

[0160] By measuring the surface profile features, calculate the maximum height R of the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com