Anti-floating-free combined core mold for hollow floor slab

A technology of hollow floor slabs and mandrels, applied in the field of floor slabs, can solve the problems of building formwork damage, affecting service life, and high labor intensity, and achieve the effects of reducing anti-floating costs, light weight, and reducing pouring costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

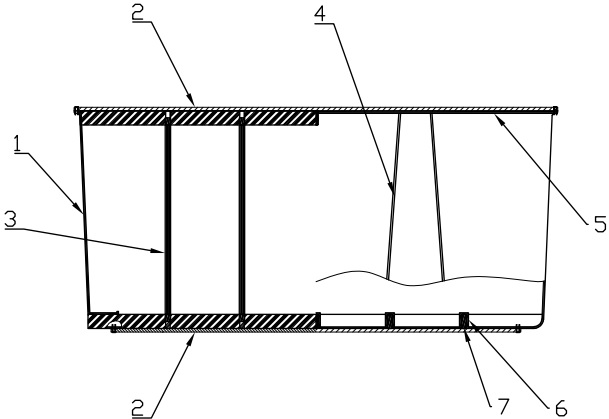

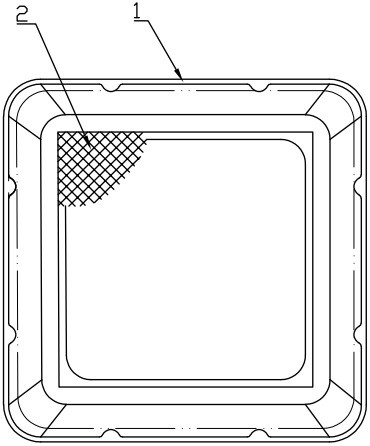

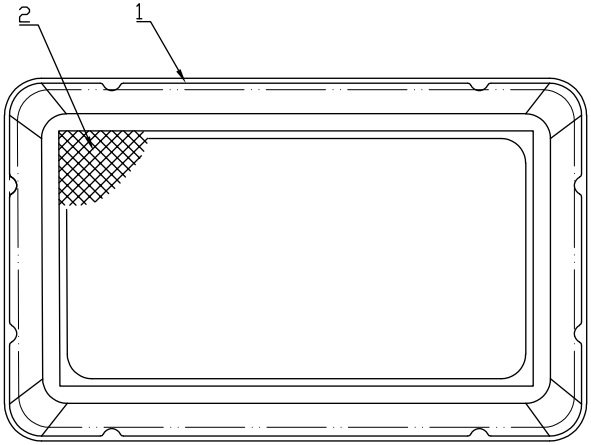

[0021] like figure 1 As shown, an anti-floating composite mandrel for a hollow floor slab in this embodiment includes a mandrel body 1 , a grid plate 2 , a lateral support bar 7 , and a vertical support bar 3 . The upper and lower sides of the core mold body 1 are open, and the surrounding walls are densely plate-shaped; the grid plate 2 covers the upper and lower openings of the core mold body 1 and fixes the nails with the core mold body through the grid plate. 1 is fixedly connected, the grid plate 2 is provided with regular or irregular mesh holes, the size of the mesh holes is smaller than the diameter of the fine sand used for building concrete, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com