Construction method of high pier column straining beam

A construction method, high pier column technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of slow construction speed, safety accidents, long construction period, etc., reduce the number of materials and machinery, speed up construction speed, shorten The effect of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

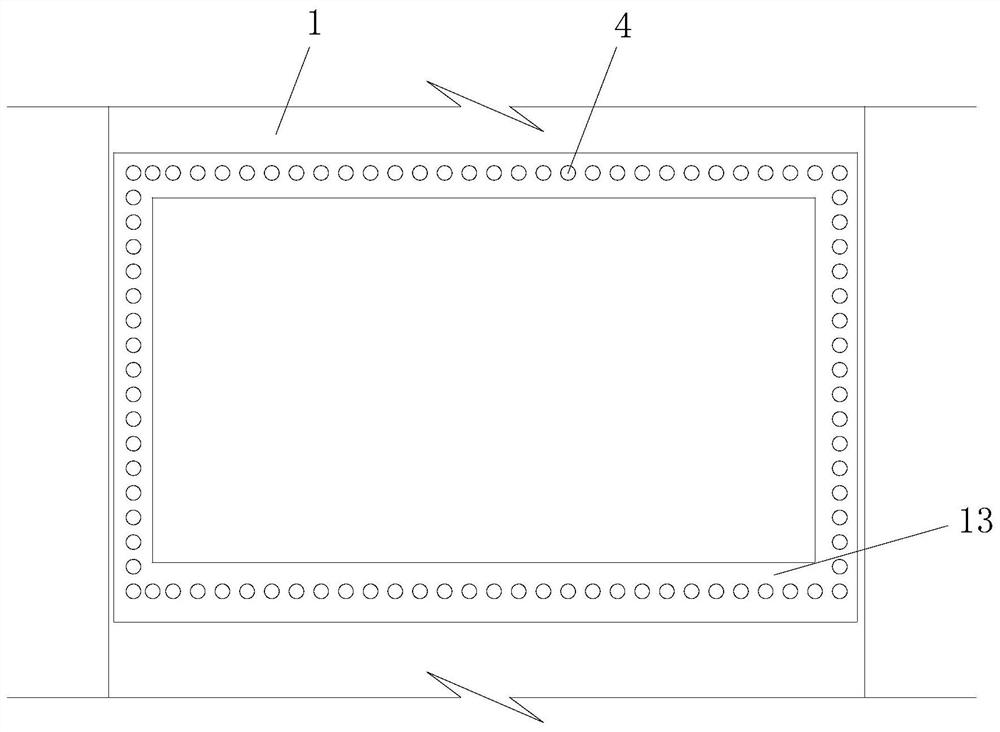

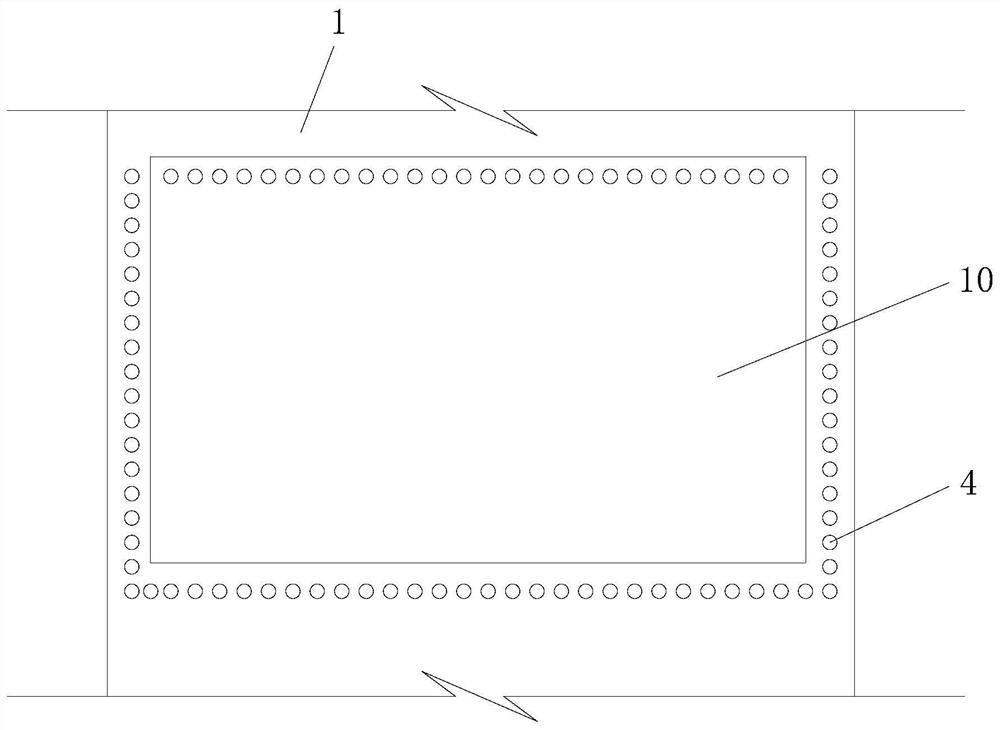

[0026] The construction method of the high pier column system beam and the embodiment of the construction method thereof will be described below with reference to the accompanying drawings. As those skilled in the art would realize, the described embodiments may be modified in various different ways, all without departing from the spirit and scope of the present invention. Accordingly, the drawings and description are illustrative in nature and not intended to limit the scope of the claims. Also, in this specification, the drawings are not drawn to scale, and like reference numerals denote like parts.

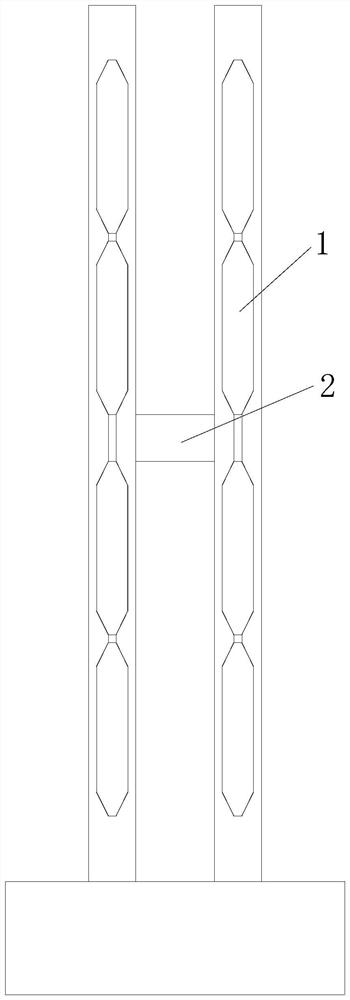

[0027] figure 1 It is a structural schematic diagram of a high pier involved in an embodiment of the present invention. In the figure, a tie beam 2 connecting the two high pier columns 1 is arranged between the two high pier columns 1 . In the traditional method, formwork needs to be set up at the tie beam 2, and the steel bar binding and concrete pouring of the tie beam 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com