Blast burner oxygen supply device for heating in glass teacup production

An oxygen supply device and blowtorch technology, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve the problems of inability to adjust different positions of glass cups, blowtorch without oxygen supply equipment, and low flame temperature of gas spray guns, etc. , to achieve the effect of increasing practicability, easy control and improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

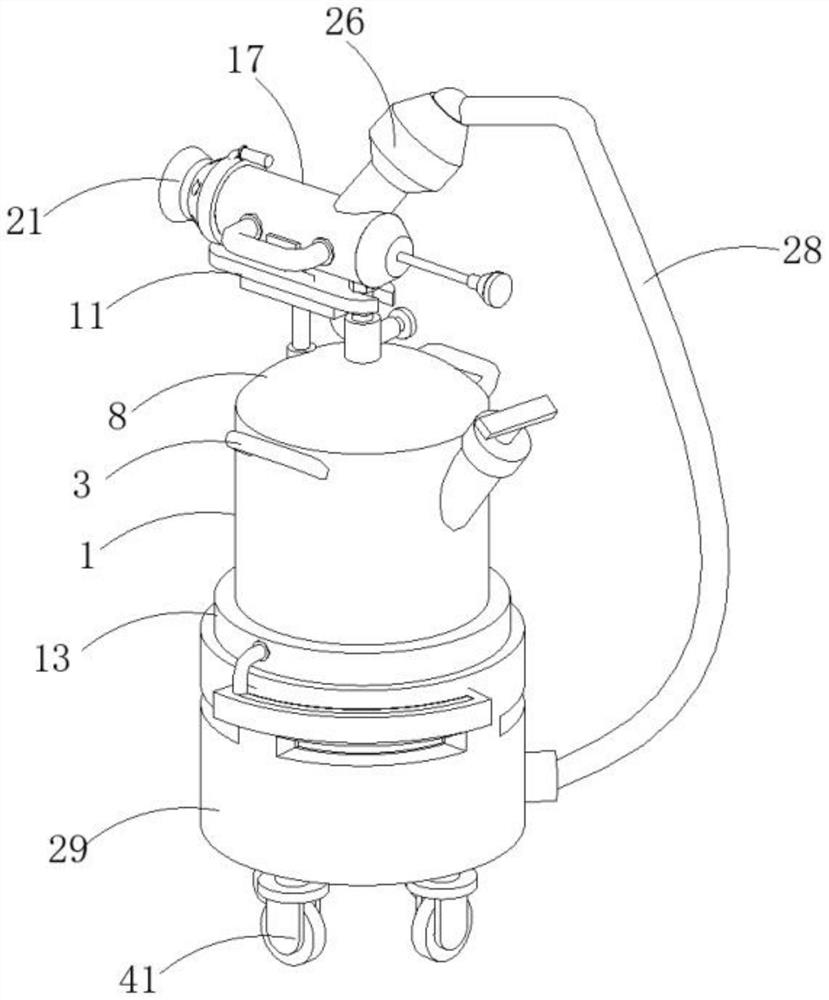

[0032] The present invention provides such Figure 1-4 The shown blowtorch oxygen supply device for glass teacup production and heating includes a gas tank 1, an inner compartment 4 is provided on the top of the gas tank 1, and a storage tray 6 is movable inside the inner compartment 4, and a ventilation soft box is installed inside the storage tray 6. The output end of the pipe 7 and the ventilation hose 7 are movably installed on the input end of the blowtorch 17, and the output end of the blowtorch 17 is fixedly installed with a nozzle 21, and the inside of the nozzle 21 is movable to install a rotating baffle 24, and the outer surface of the blowtorch 17 is fixedly installed with an oxygen charging rod 26, The input end of the oxygen charging rod 26 is movably connected to the bottom box 29 through the oxygen supply hose 28. The outer surface of the bottom box 29 is equidistantly provided with slots 30, and the inside of the bottom box 29 is equipped with a movable inner bo...

Embodiment 2

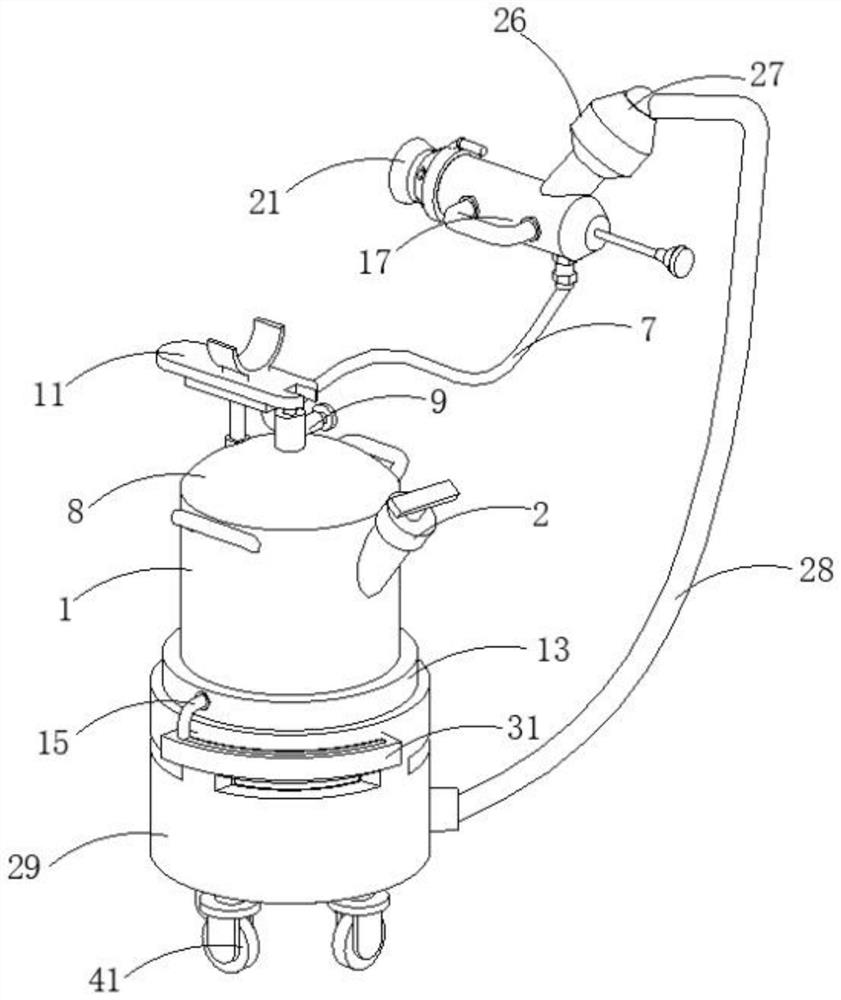

[0038] On the other hand, the present invention provides such as Figure 5-8 Shown is a blowtorch oxygen supply device for glass teacup production and heating. The lower part of the outer surface of the blowtorch 17 is fixedly installed with a limit connecting pipe 18, and the blowtorch 17 is movable and bolted inside the limit connecting pipe 18. The rod 19 and the outer surface of the blowtorch 17 are fixedly equipped with a mobile handle 20, and the limit connecting pipe 18 can ensure the stability of the output end of the ventilation hose 7. At the same time, the staff can adjust the internal pressure of the blowtorch 17 by rotating the pressure rod 19. To achieve the purpose of controlling the internal fuel injection efficiency, through the fixed installation of the mobile handle 20, the staff can better move the blowtorch 17 and control the use position of the blowtorch 17.

[0039] The outer surface of the nozzle 21 is equidistantly opened with air inlets 22, the front ...

Embodiment 3

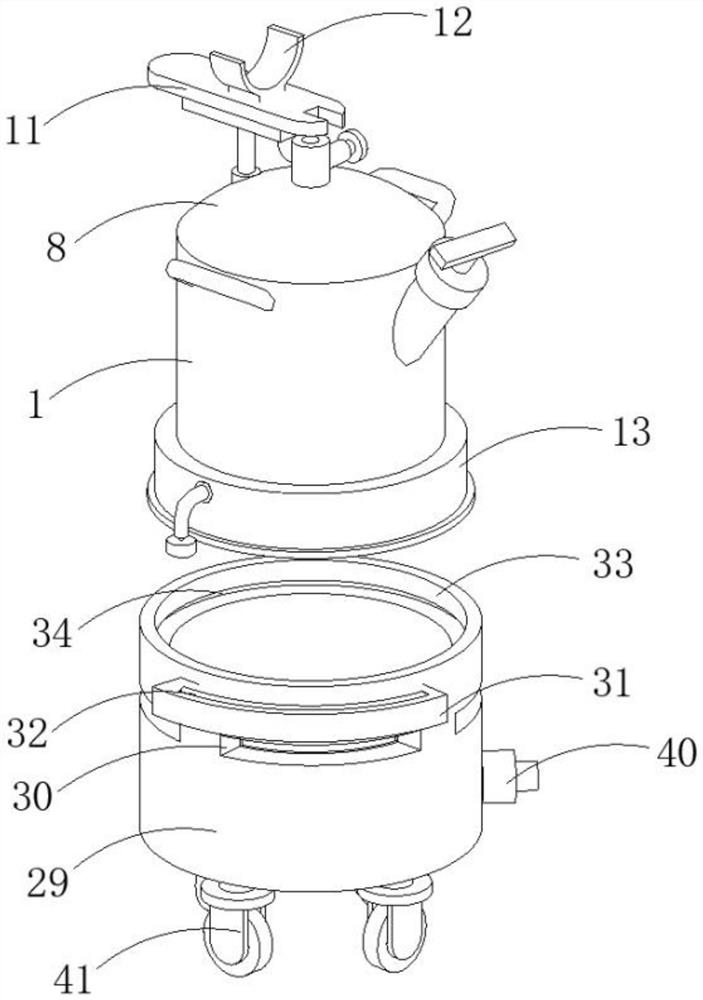

[0043] On the other hand, the present invention provides such as Figure 9-11 Shown is a blowtorch oxygen supply device for glass teacup production and heating. The outer surface of the bottom box 29 corresponds to the position of the control pole 15 and is fixedly installed with a limit block 31. The inside of the limit block 31 is provided with a chute 32, and the outer surface of the slide block 16 is pasted. The inner wall of the closing chute 32 is movable and installed, and the upper part of the bottom box 29 is provided with a placement table 33 corresponding to the position of the protective bottom cover 13, and the inside of the placement table 33 is provided with a limit chute 34 at a position corresponding to the limit plate 14, through the limit block 31 and the chute 32 The control pole 15 and the slide block 16 are limited, and the positioning platform 33 and the limit chute 34 cooperate with the limit plate 14 to limit the protection bottom cover 13, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com