Height-adjustable pipeline storage structure

A storage structure and adjustable technology, applied in bottle/can parts, containers to prevent mechanical damage, lifting devices, etc., can solve the problems of reducing the production efficiency of thermal insulation pipes, unable to realize automatic pipe hoisting, etc., to improve processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

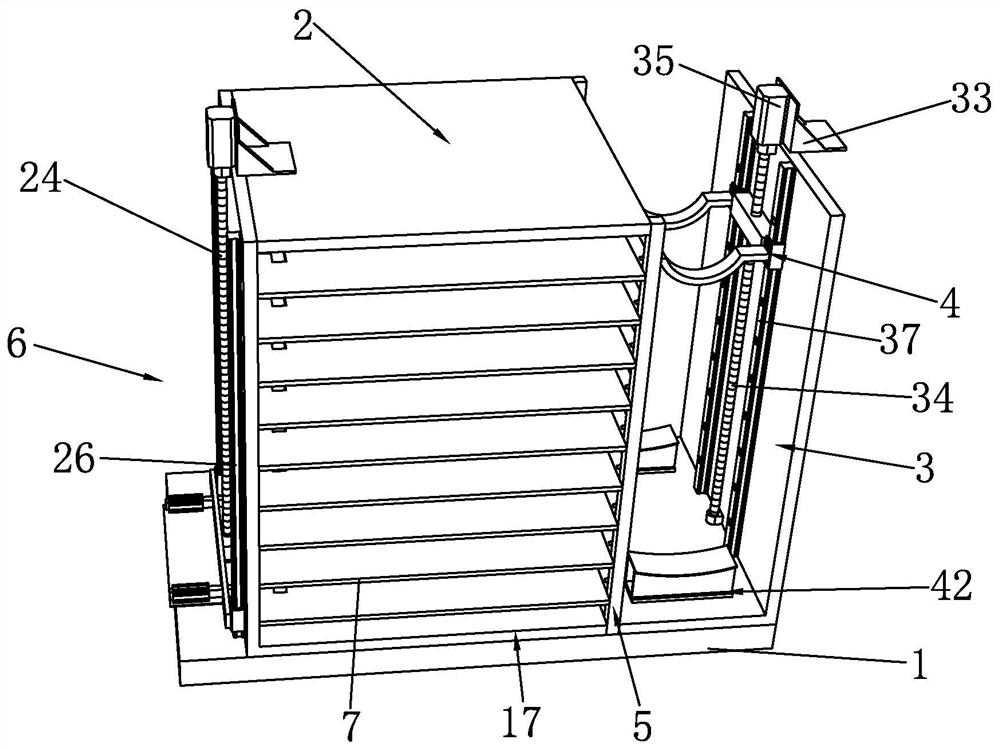

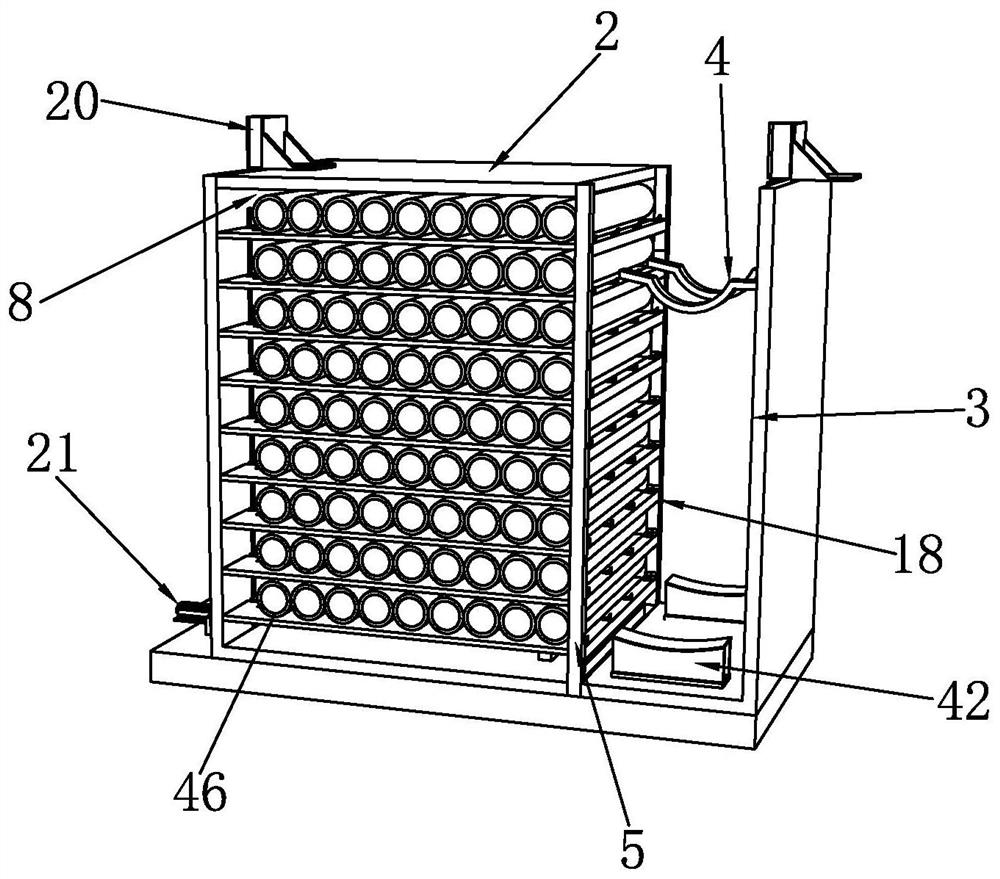

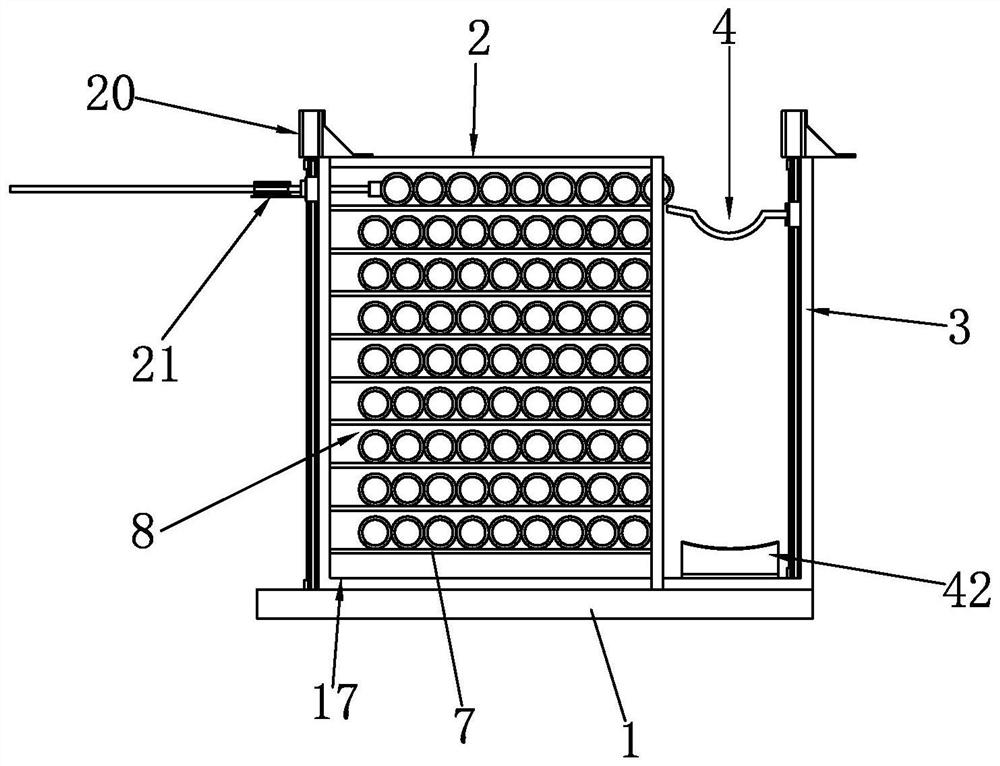

[0033] Such as Figure 1 to Figure 11 As shown, it is the height-adjustable pipeline storage structure of the present invention, which includes a storage rack 2 and a temporary storage rack 3 arranged on the base 1. The temporary storage rack 3 is arranged on one side of the storage rack 2, and the temporary storage rack 3 is close to the storage rack. One side of the storage rack 2 is provided with a transfer assembly 4, and the side of the storage rack 2 close to the temporary storage rack 3 is provided with a limit assembly 5. The limit assembly 5 is used to limit the pipeline 46 in the storage rack 2, and the other side of the storage rack 2 A pushing mechanism 6 is provided, and the pushing mechanism 6 transports the pipelines 46 in the storage rack 2 to the temporary storage rack 3 through the transfer assembly 4 one by one.

[0034] Partitions 7 are evenly distributed in the storage rack 2 , and the partitions 7 separate the storage rack 2 to form a storage cavity 8 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com