Portable stay wire hemp strand manufacturing tool

A tool-making and portable technology, applied in the direction of manufacturing tools, overhead line/cable equipment, wrench, etc., can solve the problems of easily damaged surface layer, uneven length, endangering the safety of distribution network lines, etc., to improve the quality of operation and maintenance, Change the safety risk and solve the effect of iron wire rusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

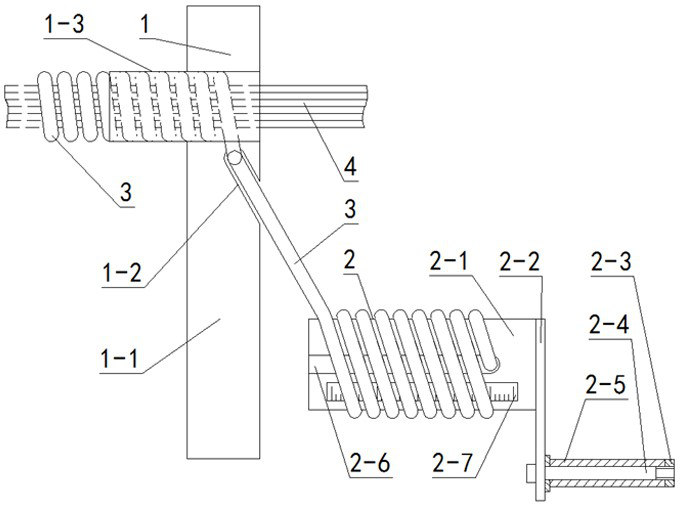

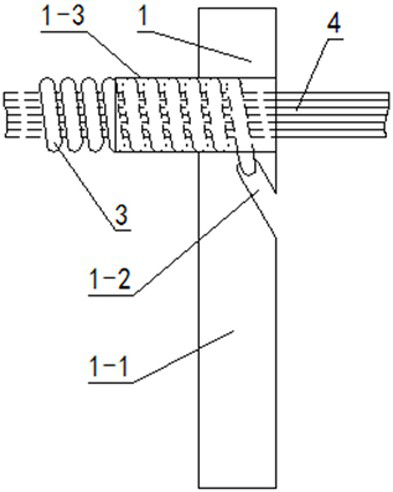

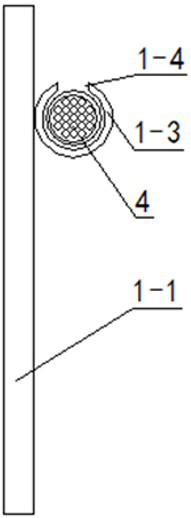

[0020] Example 1, such as Figure 1-Figure 6 As shown, the present invention provides a portable tool for making hemp strands, the structure of which includes a hemp strand binding device (1) and a wire winding device (2). The hemp strand binding device (1) consists of a wrench (1- 1) and a winding rod (1-3), the wrench (1-1) is square, with a gap A (1-2) on its left side, and the wrench (1-1) is perpendicular to the gap A (1 -2) A winding rod (1-3) is fixed on one side, the winding rod (1-3) is a hollow cylinder with a gap B (1-4) on the upper part, and the wire coiling device (2) It consists of a roller (2-1), a rocker (2-2), an end cover (2-3), a rocker shaft (2-4), a sleeve (2-5), and a baffle (2-8). The drum (2-1) is a hollow cylinder with a gap C (2-6) in its length, and a scale (2-7) is fixed at the bottom of the gap C (2-6). The drum ( 2-1) The right end is fixed with a crank handle (2-2), and the rocker handle (2-2) is a rectangular slat, and its lower end is sleeve...

Embodiment 2

[0024] Example 2, such as Figure 1-Figure 6 As shown, the present invention provides a portable tool for making hemp strands, the structure of which includes a hemp strand binding device (1) and a wire winding device (2). The hemp strand binding device (1) consists of a wrench (1- 1) and a winding rod (1-3), the wrench (1-1) is circular, with a gap A (1-2) on the left side, and the wrench (1-1) is perpendicular to the gap A ( 1-2) A winding rod (1-3) is fixed on one side. The winding rod (1-3) is a hollow cylinder with a gap B (1-4) on its upper part. The wire coiling device (2 ) consists of a roller (2-1), a rocker (2-2), an end cover (2-3), a rocker shaft (2-4), a sleeve (2-5), and a baffle (2-8) , the drum (2-1) is a hollow cylinder with a gap C (2-6) in its length, and a scale (2-7) is fixed at the bottom of the gap C (2-6). (2-1) A crank handle (2-2) is fixed on the right end, and the rocker handle (2-2) is a rectangular slat, and a rocker shaft (2-4) is sleeved on its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com