An improved pay-off frame structure

A pay-off stand, an improved technology, is applied in the manufacture of electrical components, circuits, cables/conductors, etc. It can solve the problems of poor outlet, more scratches on cables, and cable quality problems, and achieves simple and reliable structure, Ensuring a clean environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

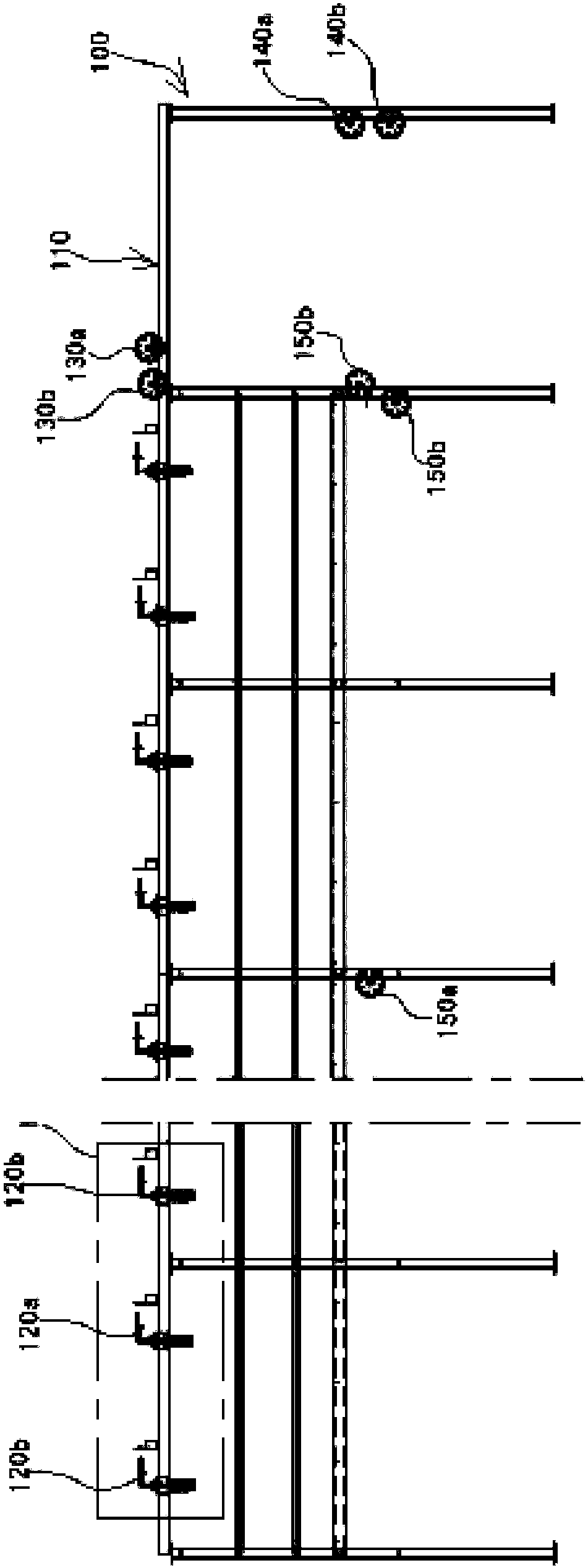

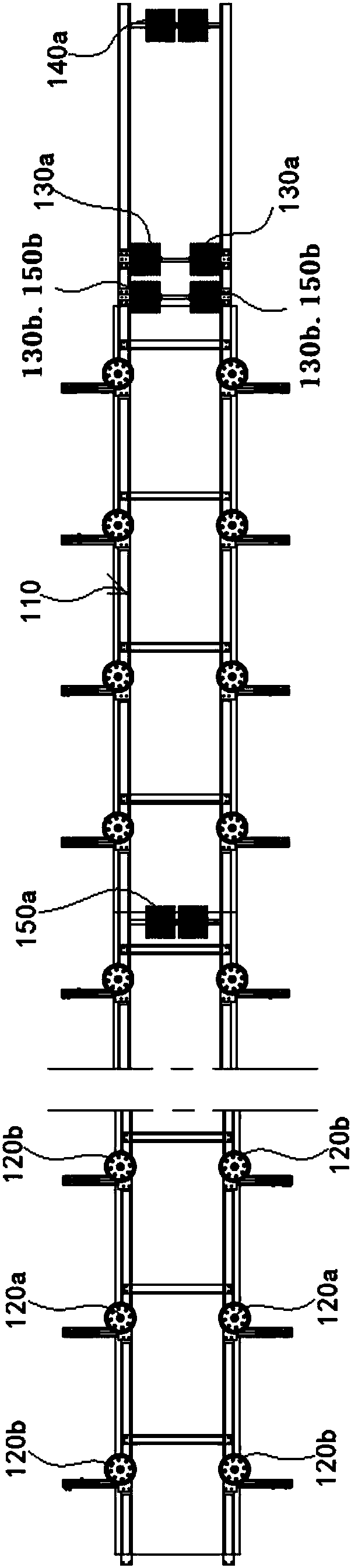

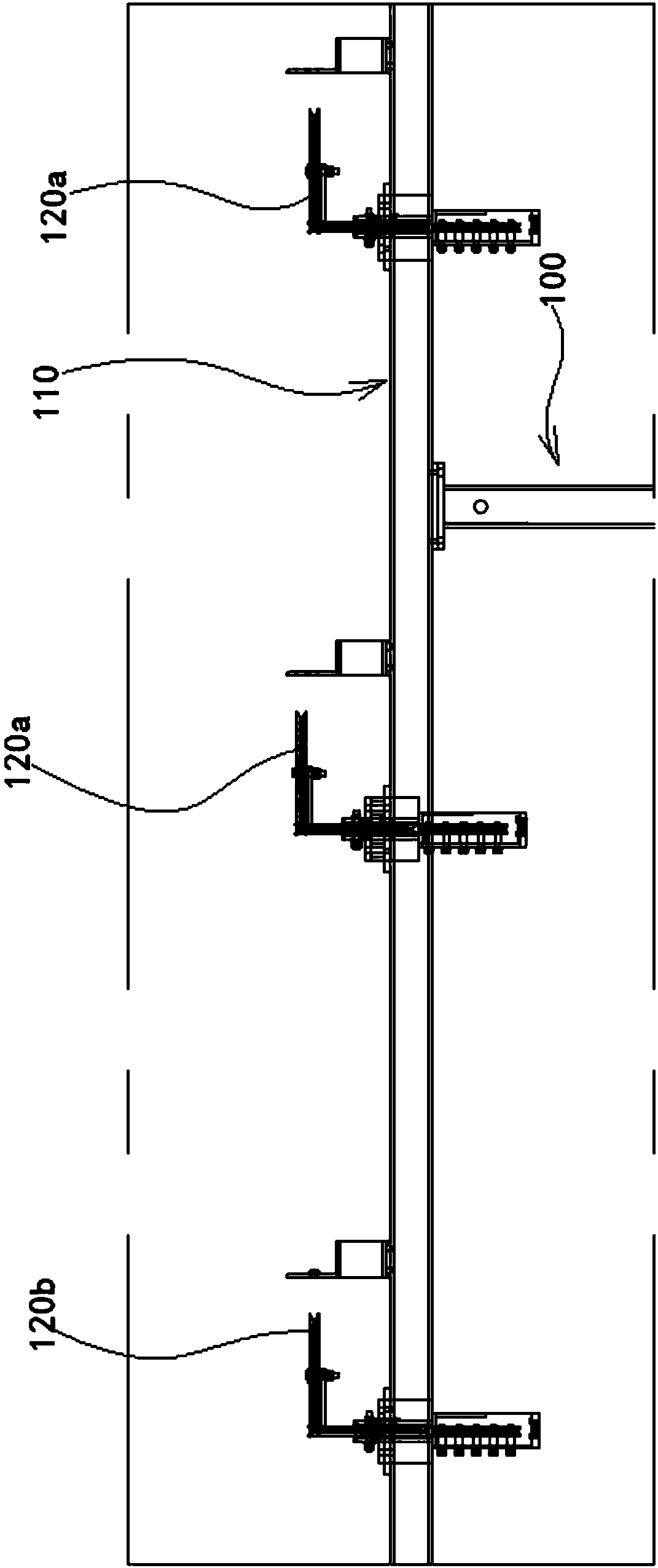

[0027] see Figure 1 to Figure 7 An improved pay-off frame structure shown includes a long pay-off frame 100 extending along the pay-off direction, and installation beams 110 are arranged on the tops of both sides of the long pay-off frame 100 along the length direction, and each installation beam 110 has an upper edge A number of high guide wheels 120a and low guide wheels 120b are arranged at staggered intervals in the length direction. Ten high guide wheels 120a and ten low guide wheels 120b are arranged at staggered intervals along the length direction on each mounting beam 110 in this embodiment, and the high guide wheels 120a and low guide wheels 120b are arranged horizontally, and the high guide wheels 120a The height is higher than that of the low guide wheel 120b. This e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com