A system and method for automatically sorting materials based on intelligent robots

A kind of intelligent robot and robot technology, applied in manipulators, comprehensive factory control, metal processing, etc., can solve the problems of manual identification of materials that are easy to be misdetected or missed, low production efficiency, low efficiency, etc., to reduce the risk of mixing materials, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

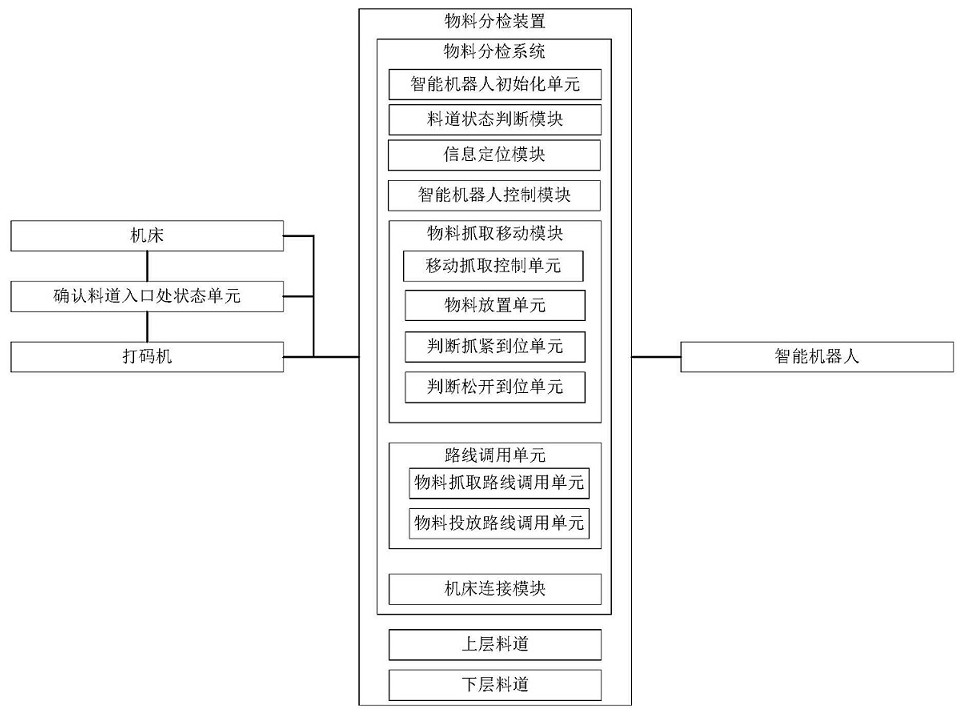

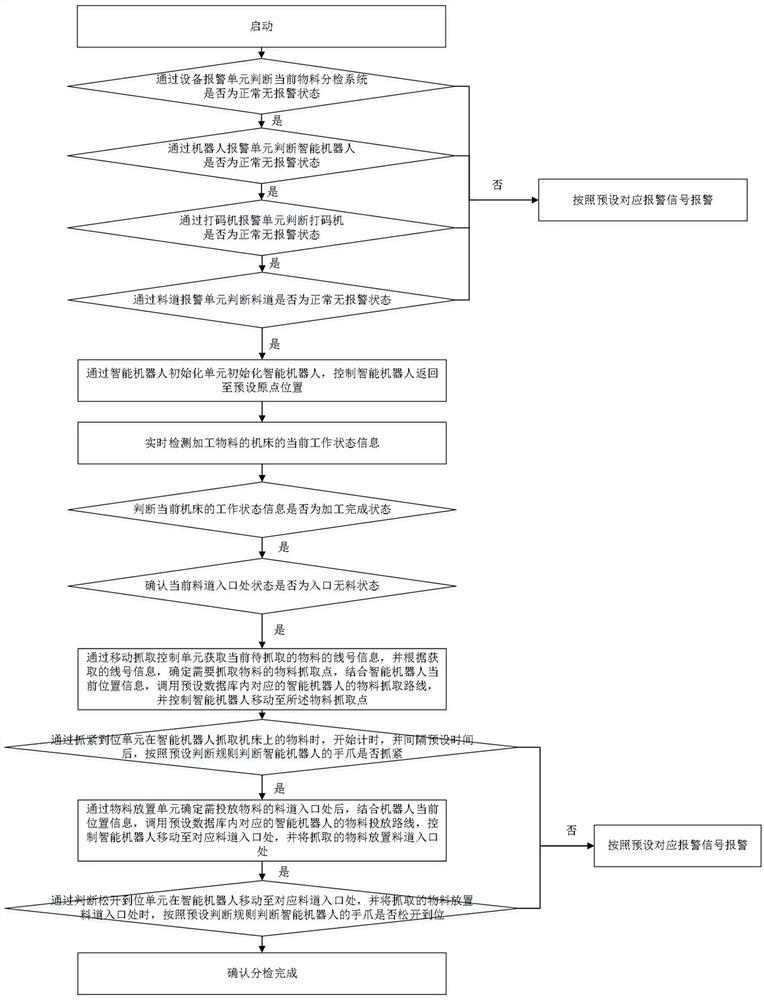

[0035] The present embodiment provides a system based on intelligent robot automatic material sorting, such as Figure 1 As shown, the system includes an intelligent robot, a material inspection device and a coding machine, the material separation device comprises a material separation system, an upper forehear and a lower forehear; The material separation system includes a machine tool connection module, a foretrack state judgment module, an information positioning module, and an intelligent robot control module;

[0036] The coding machine alternately engraves different line number information to the material, through the intelligent robot to the machine tool feeding, intelligent robot in the different machine tool completion signal, the robot through the program to judge, call the corresponding material grasping program, respectively, the material corresponding to the preset first line number machine tool and the preset second line machine tool materials placed to the correspond...

Embodiment 2

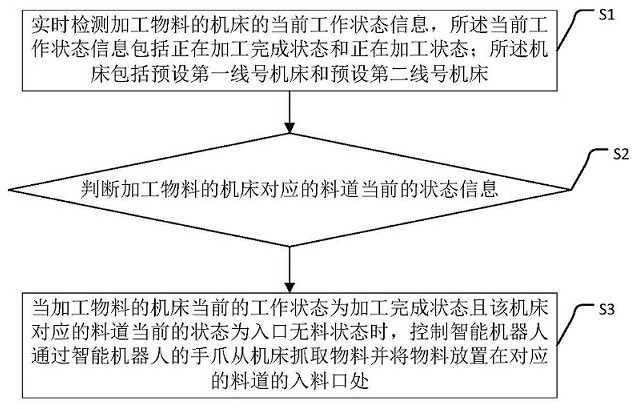

[0065] The present embodiment provides a method based on intelligent robot automatic sorting of materials, such as Figure 2 As shown, this method includes steps:

[0066] S1: Real-time detection of the current working state information of the machine tool of the processing material, the current working state information includes the processing completion state and the processing state; The machine tool comprises a preset first line number machine tool and a preset second line number machine tool;

[0067] S2: To determine the current state information of the machine tool corresponding to the machine tool for processing materials, the foreheel includes the inlet and outlet respectively; The current state information of the forehearth includes the inlet material state and the inlet materialless state;

[0068] The forehear includes an upper foretrack and a lower forehear, the upper forehear for placing the material processed by the preset first line machine tool, the lower forepass fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com