Centralized control system for electrical test equipment

A centralized control system and electrical testing technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems that affect production line operation efficiency, product quality problems, and low efficiency of equipment data utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Shown in conjunction with accompanying drawing, the technical scheme of the present invention is further described:

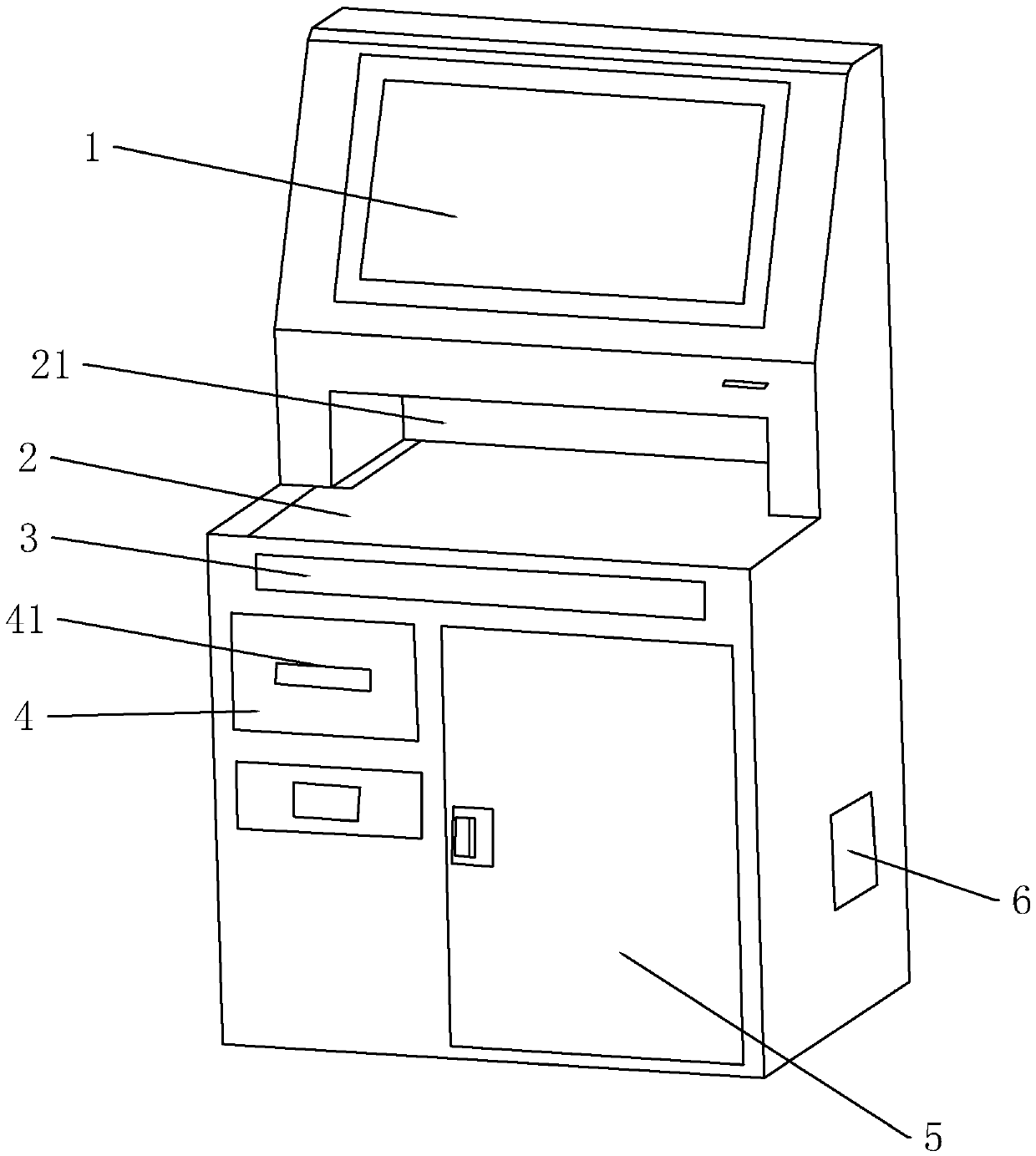

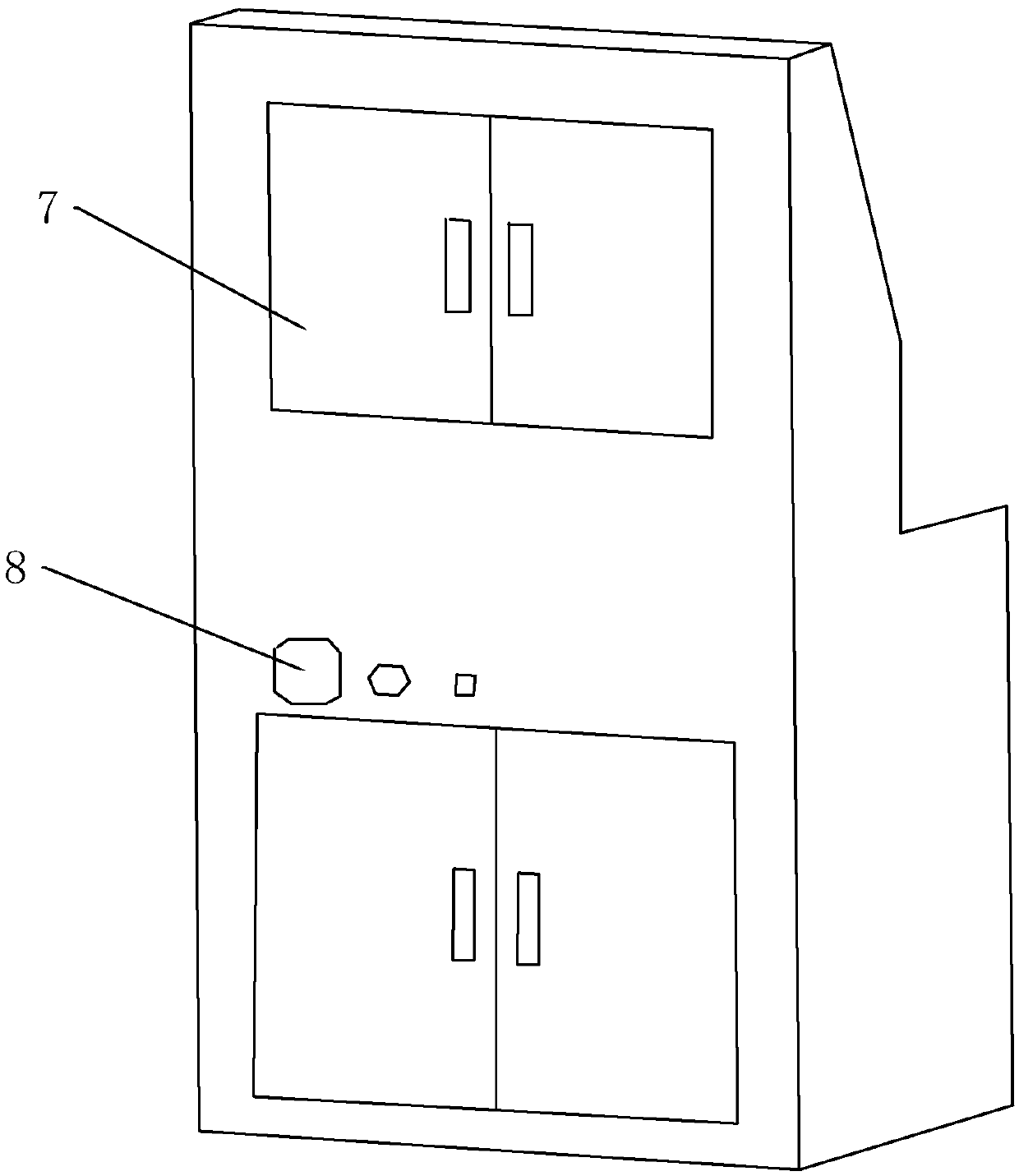

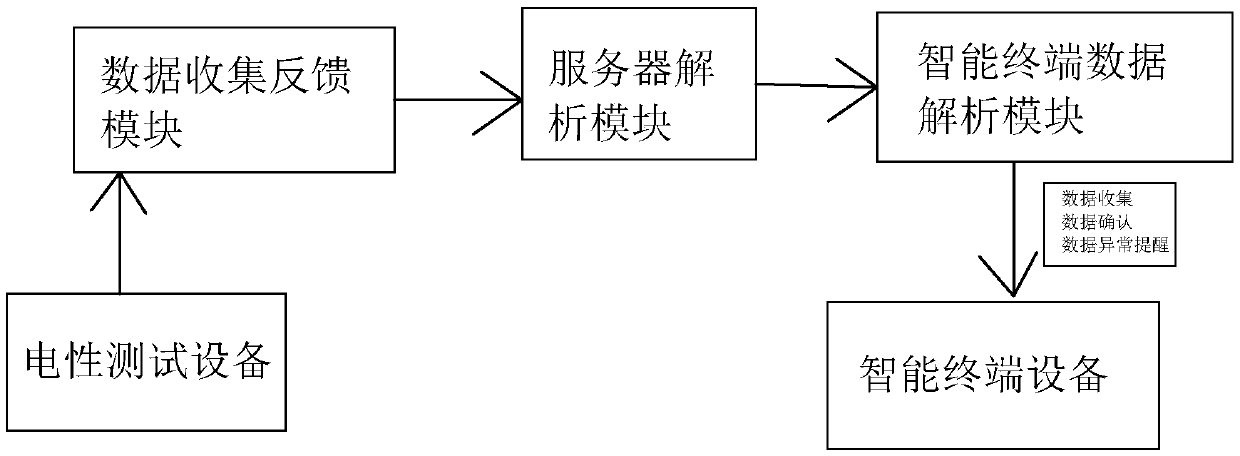

[0020] A centralized control system for electrical testing equipment, comprising a system hardware unit and a system software unit, the system software unit is arranged inside the system hardware unit, the hardware unit is provided with a working surface 2, and a touch screen display is arranged above the working surface 2 1. There is a product placement opening 21 between the touch screen display 1 and the work surface 2. A keyboard drawer 3 is provided on the front under the work surface 2. An item placement area 5 and a label printer drawer 4 are arranged below the keyboard drawer 3. The work surface 2. A heat dissipation fan 6 is arranged on the lower side, and a power supply and a network interface 8 are arranged on the back of the system hardware unit. The system software unit includes a data collection and feedback module, and the electrical testin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com