Machining process for thin-wall cylindrical part with boss in inner hole

A mechanical processing, cylindrical technology, applied in the field of mechanical processing, can solve the problems of long slotting processing time, large processing allowance, poor cutting state, etc., and achieve the advantages of saving processing time, large processing allowance and long processing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

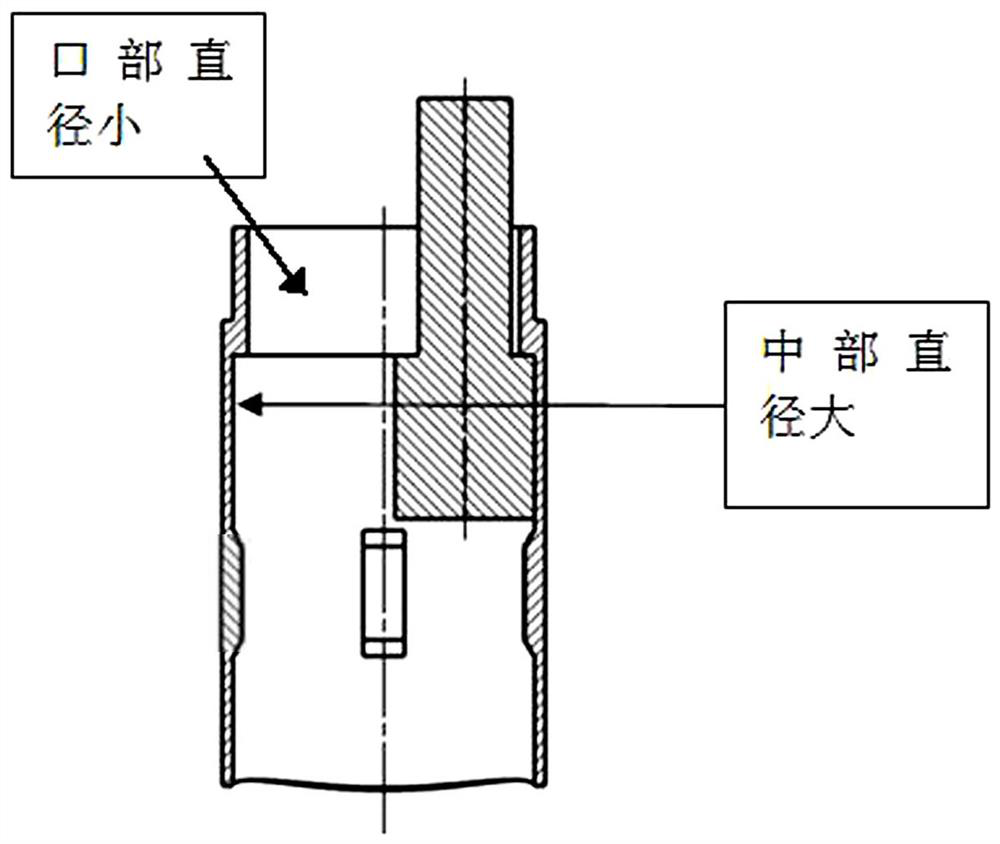

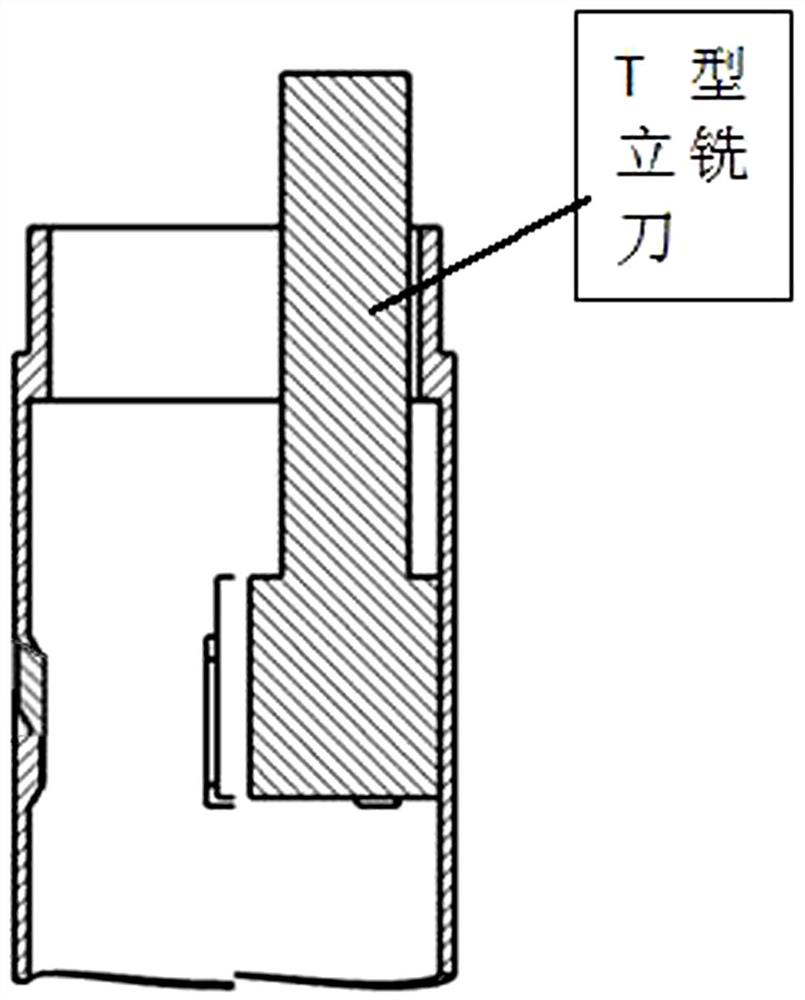

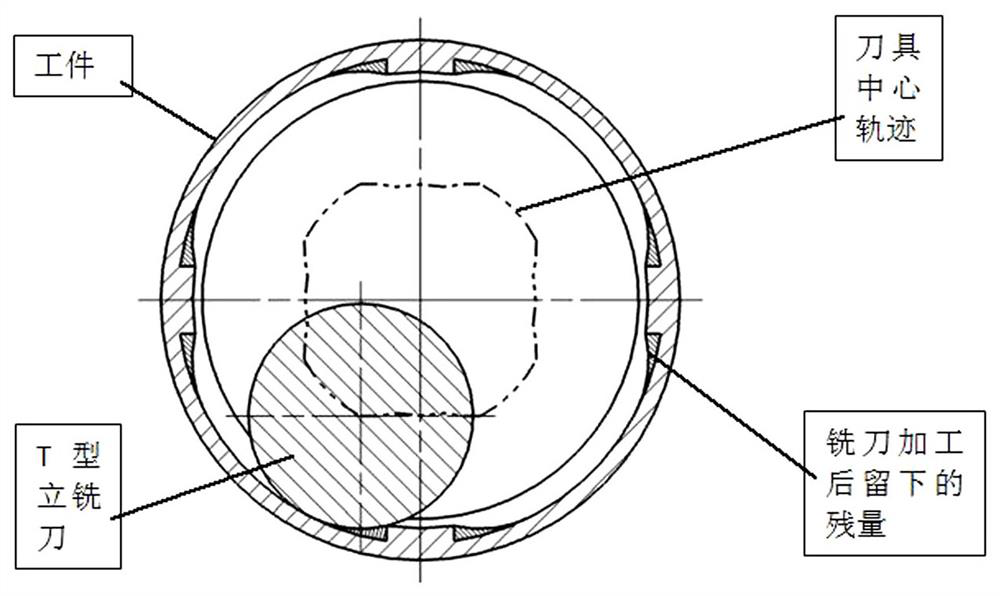

[0022] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. Such as Figure 1-5 Shown: a machining process for a thin-walled cylindrical part with a boss in the inner hole, including the following steps:

[0023] Step 1. First complete the rough turning inner shape of the pipe body-rough turning shape-half turning outer circle datum of the pipe body on an ordinary numerical control lathe;

[0024] Step 2. Select four-axis processing equipment with a turntable or dividing head, and use self-made special fixtures to wrap the semi-circular part of the tube body workpiece. After one clamping, perform fine boring at both ends of the inner shape-milling inner shape-milling The inner product of the boss - the chamfering finished product at both ends of the milling boss - the step of inserting the boss;

[0025] Step 3: Use a common CNC lathe to finely bore the end faces of both ends of the pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com