Internal turning device and method for heat insulation layer of low-temperature pipeline

A processing device and low-temperature pipeline technology, applied in the field of cutting processing, to achieve the effect of protecting service performance and service life, obvious processing efficiency, and realizing the effect of application and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

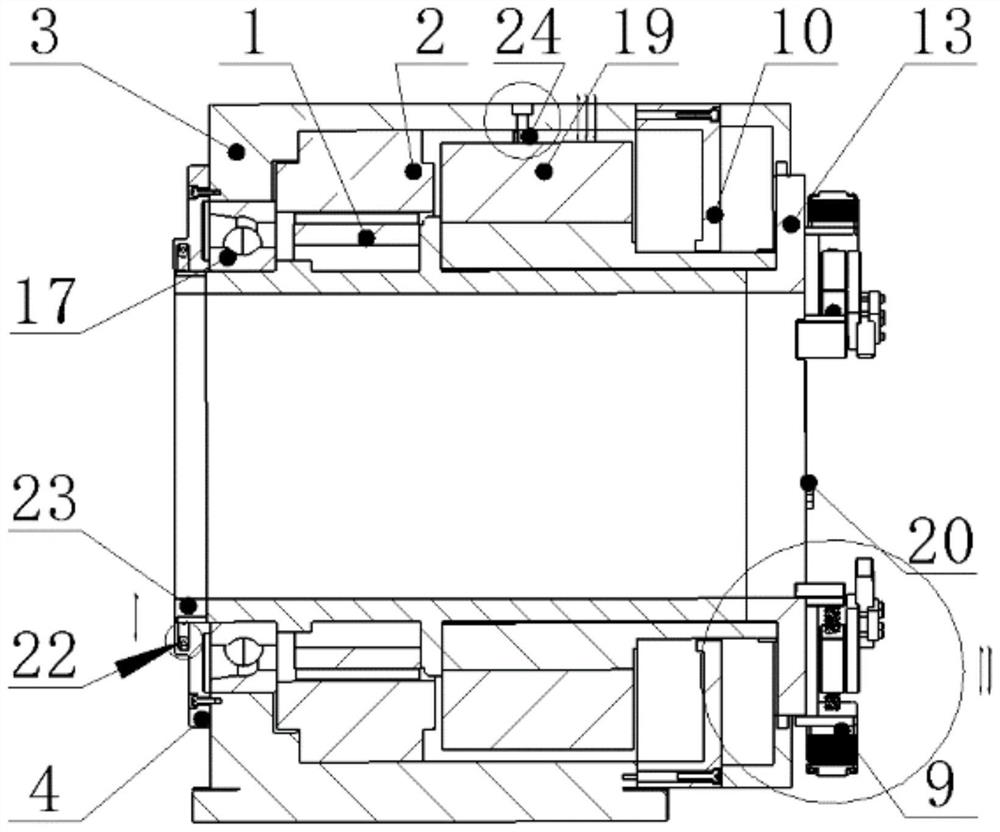

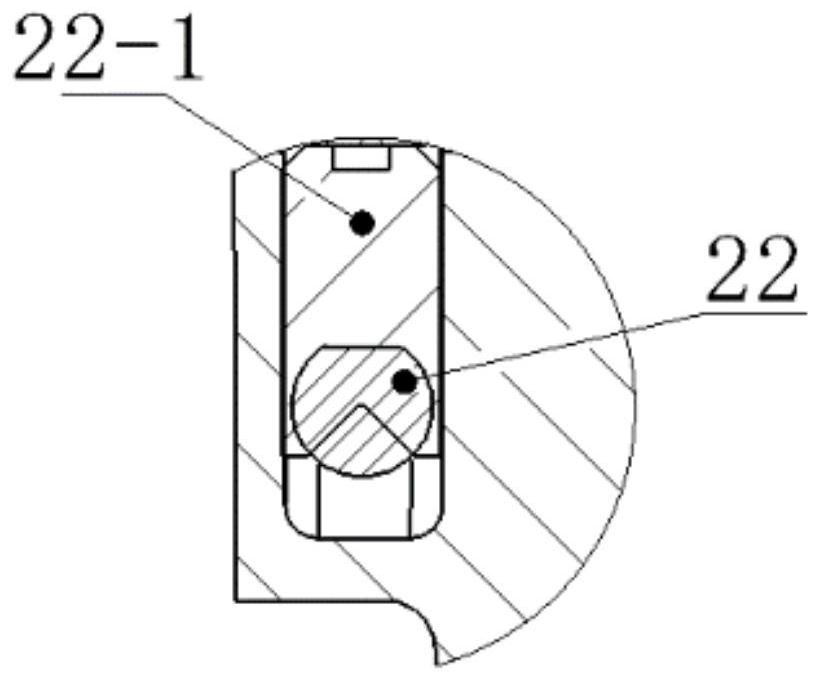

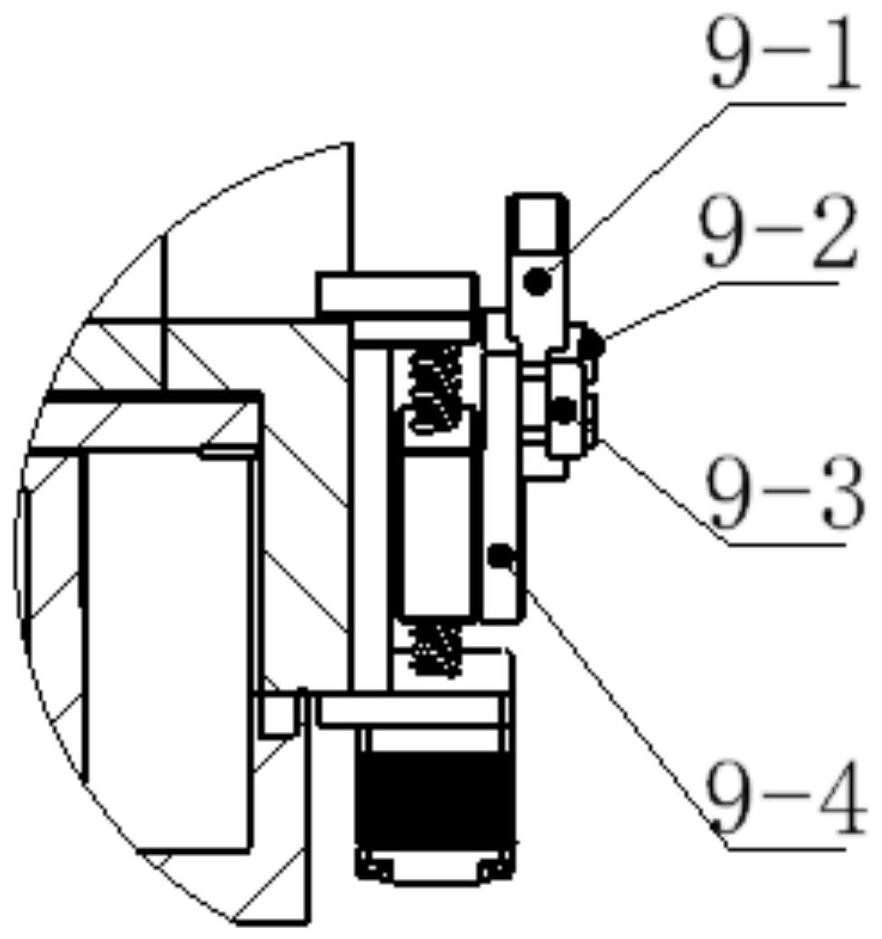

[0035] Aiming at the high-efficiency processing of the thermal insulation layer of the low-temperature pipeline in the aerospace field, the present invention has invented a turning processing device and method for the inner-turning processing of the low-temperature pipeline thermal insulation layer with a compact structure. Structure The two ends of the low-temperature pipeline are fixed and clamped, and the pipeline is fixed by multi-point floating support in the middle section of the pipeline to reduce the deflection and deformation of the heat-insulated pipeline due to its own weight and ensure the processing accuracy of the pipeline shape; figure 1 It is a cross-sectional view of the turning processing device in the heat insulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com