Special 3D printing equipment for printing hollow cylindrical component and printing method thereof

A technology of 3D printing and special equipment, applied in the field of additive manufacturing, can solve problems such as days or even a month, product deformation out of tolerance, no special equipment, etc., to improve production efficiency, simple structure, and improve product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

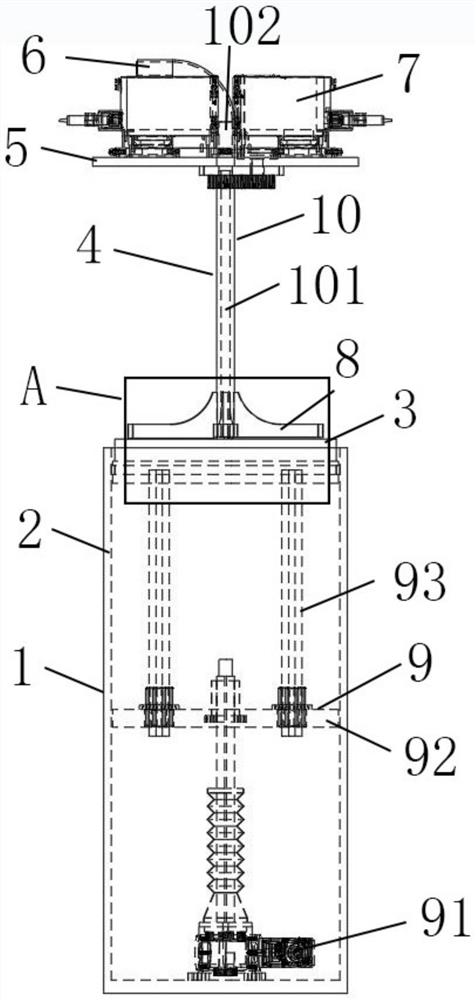

[0059] Such as figure 1 As shown, a 3D printing special equipment for printing hollow cylindrical components, including

[0060] A printing device 1, the printing device includes a device housing 2 and a printing substrate 3, the printing substrate is located inside the device housing and moves up and down inside the device housing, and the printing substrate is used to carry 3D Printing powder and formed products;

[0061] A powder spreading device 4, the powder spreading device is suspended above the printing device, the powder spreading device includes a whole platform 5, a powder feeding pipeline 6, several laser vibrating mirrors 7 and several scrapers 8,

[0062] The powder feeding pipeline is in communication with each of the scrapers, and the powder feeding pipeline is used to provide 3D printing powder to the scrapers;

[0063] Several of the laser galvanometers are located above the whole platform, and the laser galvanometers are used to emit laser light to irradia...

Embodiment 2

[0082] This embodiment is carried out on the basis of the first embodiment, and the similarities with the first embodiment will not be repeated.

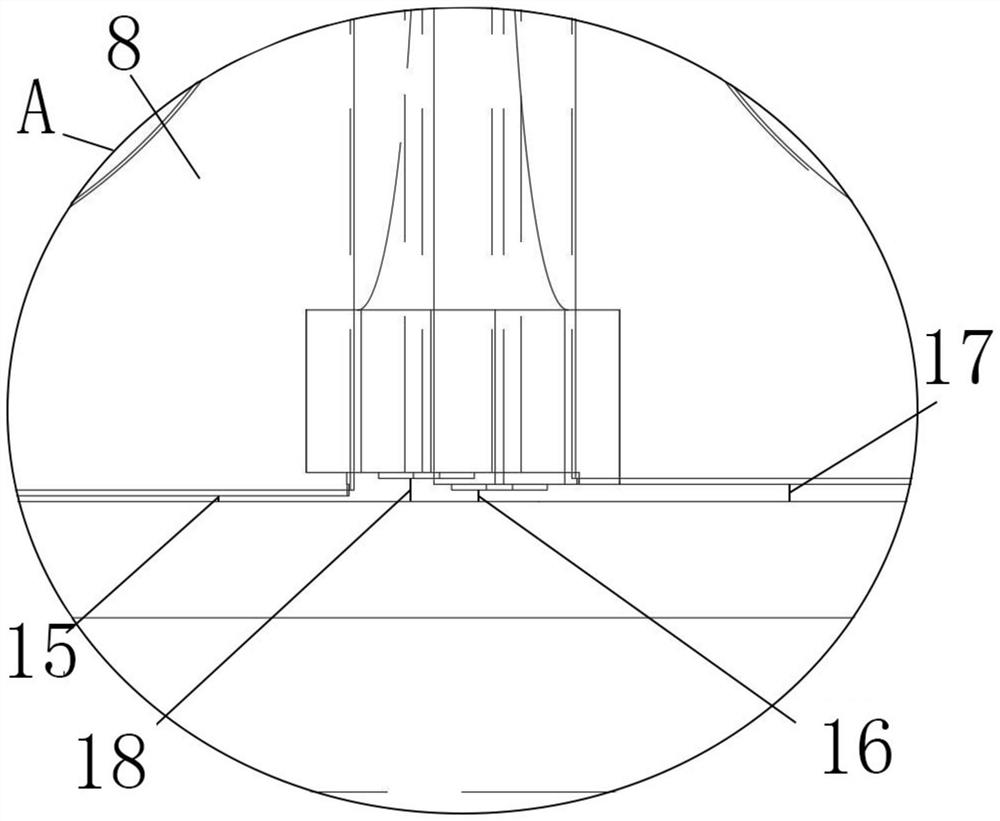

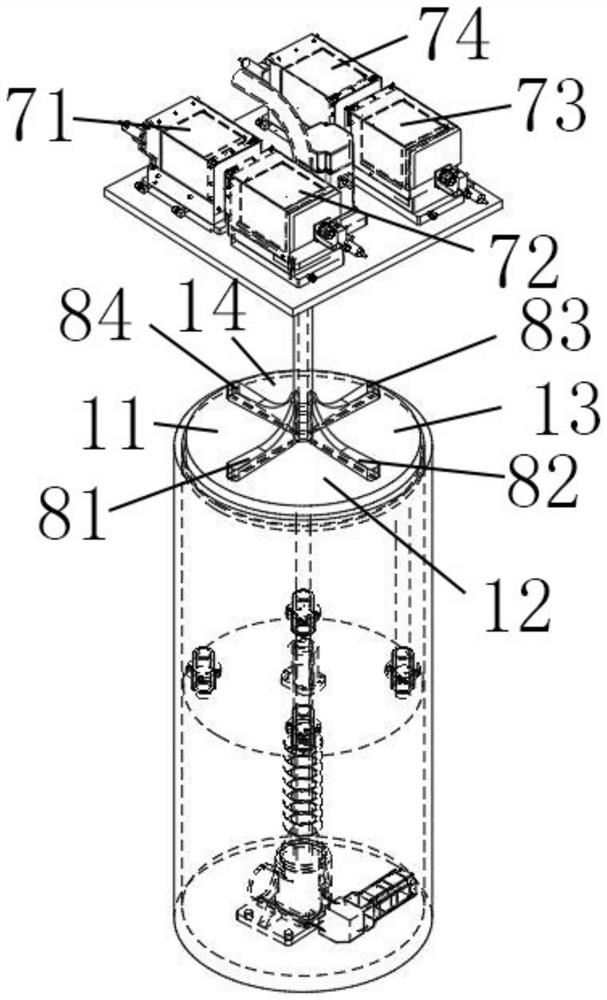

[0083] Such as Figure 2-Figure 3 As shown, the number of the scrapers is the same as the number of the laser vibrating mirrors, which are 4; the 4 scrapers are respectively a first-level step scraper 81, a second-level step scraper 82, a third-level step scraper 83 and a fourth-level step scraper. Step scraper 84; the included angle between two adjacent scrapers is 90°; 4 scrapers divide the printing substrate into printing area A11, printing area B12, printing area C13 and printing area D14; 4 The laser vibrating mirrors are respectively laser vibrating mirror A71, laser vibrating mirror B72, laser vibrating mirror C73 and fourth laser D74, the laser vibrating mirror A is located directly above the printing area A, and the laser vibrating mirror B Located directly above the printing area B, the laser vibrating mirror C is located...

Embodiment 3

[0087] This embodiment is carried out on the basis of Embodiment 1 or Embodiment 2, and the similarities with Embodiment 1 or 2 will not be repeated.

[0088] This embodiment relates to a 3D printing method for printing hollow cylindrical components, using the 3D printing special equipment described in Embodiment 1 or 2, including the following steps:

[0089] S1. Establish a three-dimensional structure model of the product to be printed, slice and layer the three-dimensional structure model, and import the layered data into the special equipment for 3D printing;

[0090] S2. Select the operating parameters and the number of partitions of the 3D printing special equipment through the layer thickness set in step S1, including the laser pulse width, power density, beam focal spot, scraper speed, printing substrate moving speed, printing layer of the laser galvanometer Thickness and printing speed;

[0091] S3. Perform initialization according to the operating parameters selecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com