Automatic non-condensable gas discharging device of evaporator for producing anhydrous sodium sulphate

An automatic discharge and evaporator technology, which is applied in evaporator accessories, evaporator adjustment/control, evaporation, etc., can solve the problem of uncontrollable discharge of non-condensable gas from the evaporator, and achieve the effect of convenient discharge of non-condensable steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

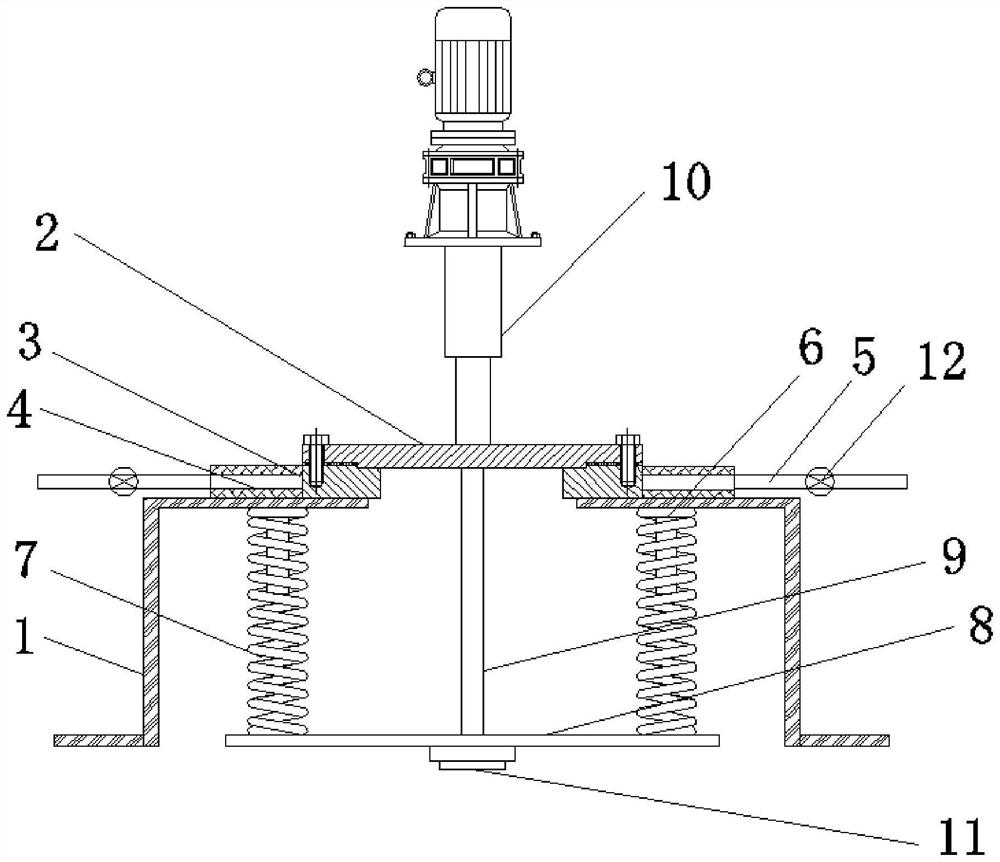

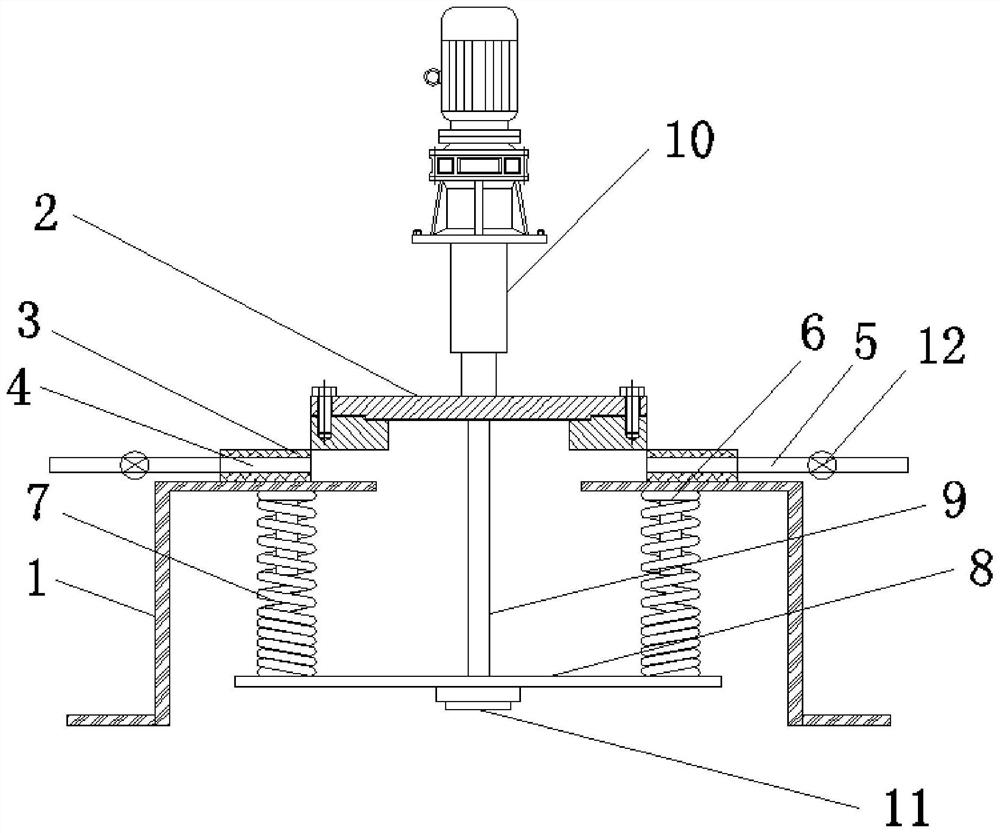

[0028] An automatic non-condensable steam discharge device for evaporators used in the production of sodium sulfate, comprising exhaust covers arranged on the outer walls of several exhaust seats of the evaporator, the outer edges of the exhaust covers are also sleeved with exhaust sleeves, the An exhaust hole is opened on the exhaust sleeve, and the exhaust hole is connected with an exhaust pipe. A number of fixed seats are arranged on the inner walls of both sides of the exhaust seat, and a number of springs are also arranged. The upper ends of the springs are sleeved On the fixed seat, the lower end of the spring is connected with a connecting plate, the middle part of the upper surface of the connecting plate is connected with a connecting rod, the other end of the connecting rod is connected with the lower wall of the exhaust cover, and an electric motor is arranged above the exhaust cover. Pull rod, the output end of the electric pull rod is connected to the upper wall of...

Embodiment 2

[0031]On the basis of Embodiment 1, a sealing ring is installed on the contact surface between the exhaust cover and the exhaust sleeve. Through this setting, when non-condensable gas is not discharged, a good seal between the exhaust cover and the exhaust sleeve is ensured.

Embodiment 3

[0033] On the basis of the above embodiments, a vacuum pump is installed on the exhaust pipe. This setting facilitates quick discharge of non-condensable steam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com