Novel motor for high-power fan

A high-power, new technology, applied in the direction of electromechanical devices, electrical components, mechanical equipment, etc., can solve the problems of low motor power, high labor costs, and difficult maintenance, so as to reduce maintenance time, improve bearing lubrication performance, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

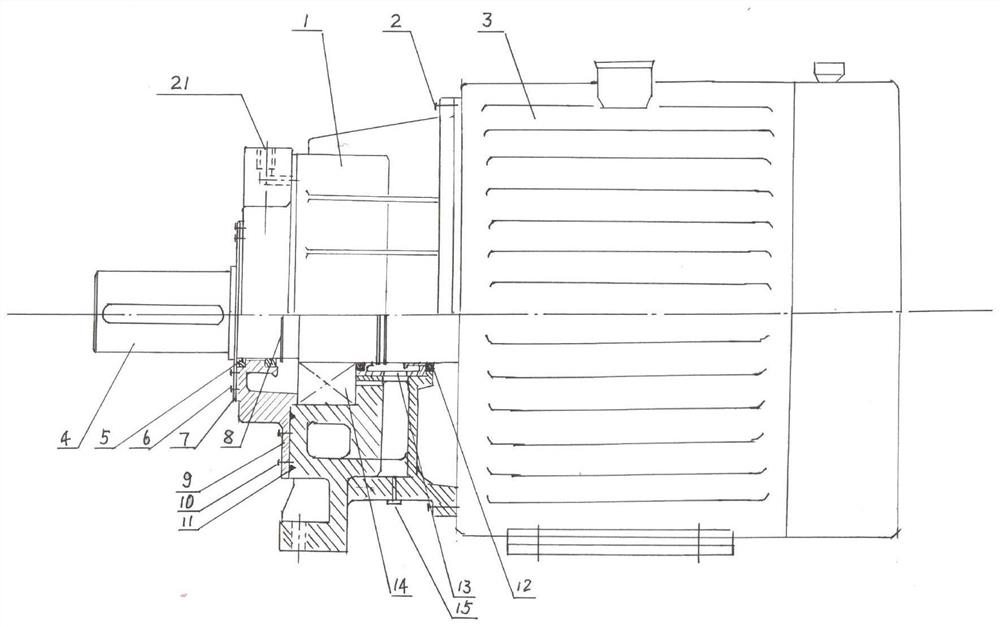

[0024] Such as Figure 1 to Figure 10 As shown, a new motor for a high-power fan includes a front bearing end cover 1, an end cover bearing gland 9, a motor housing 3, and a motor rotor 4. The front bearing end cover 1 is screwed to the motor with 8 M12 bolts 2. 3 on the casing.

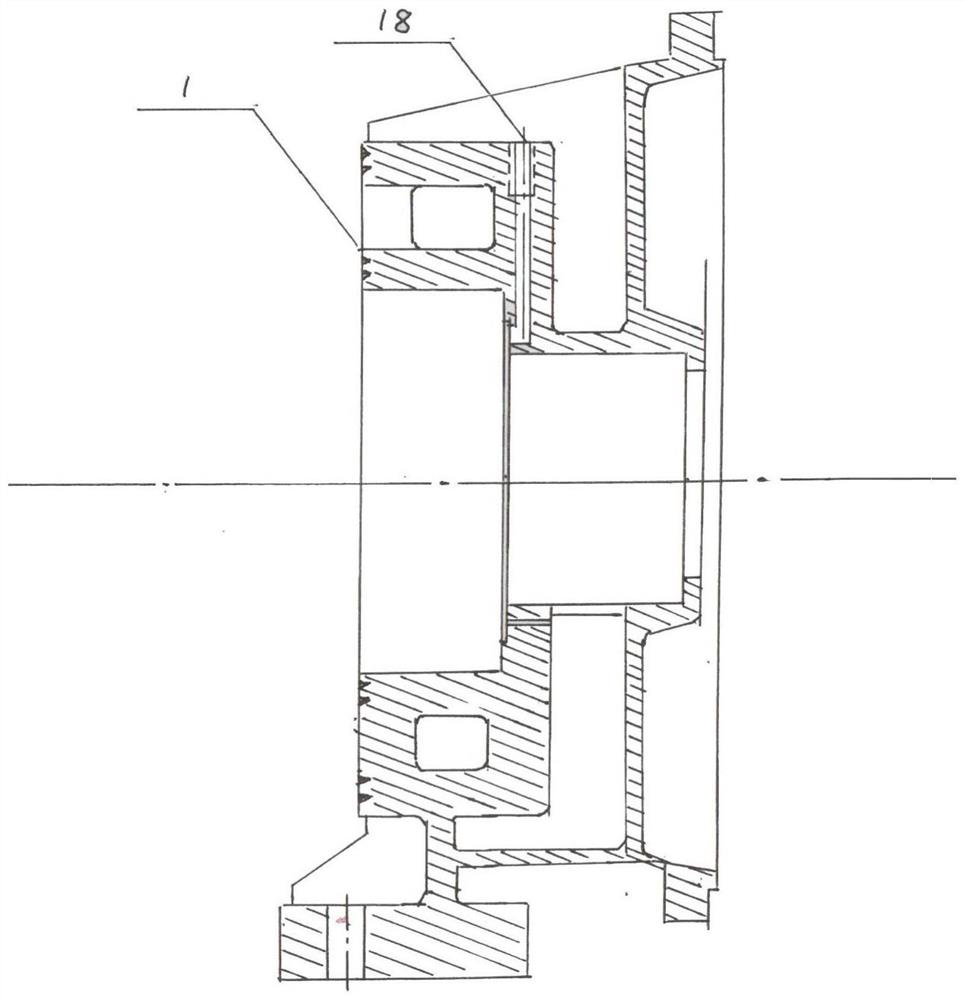

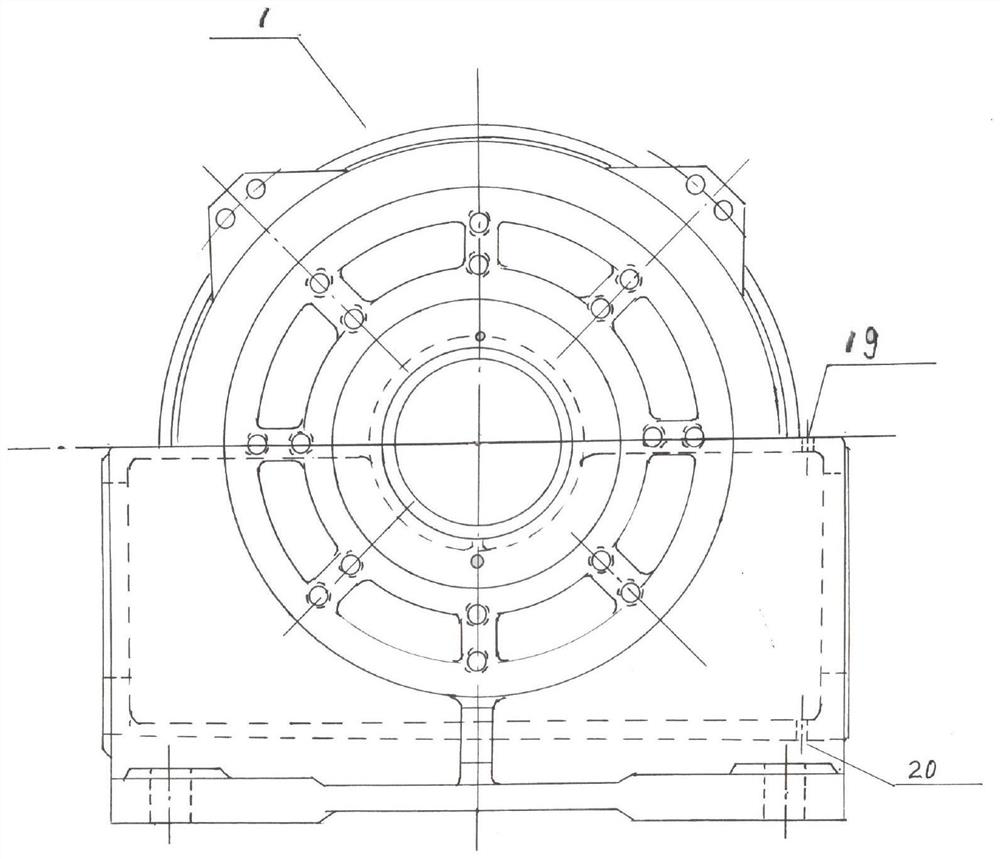

[0025] A bearing 14 is press-fitted into the front bearing end cover 1, and the bearing 14 adopts a non-destructive self-aligning roller bearing, such as image 3 As shown, the upper end surface of the front bearing end cover 1 is provided with an oil filling hole 19 blocked by M12 bolts 2, and the lower end surface of the front bearing end cover 1 is provided with an oil discharge hole 20 blocked by an M12 oil plug 15, and on the front bearing end cover 1 is provided with a vent hole 18, and the front bearing end cover 1 is equipped with an oil seal sleeve 13 with 4 oil return holes with a diameter of 8mm below, and the two ends of the oil seal sleeve 13 are respectively equipped with J-type oil se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com