Open-loop adjusting control device for oil supply switching of combined pump

An open-loop adjustment and control device technology, applied in the direction of charging system, engine components, liquid fuel feeder, etc., can solve the problems of single gear pump mechanical power loss, adjustment and control device can not be used, etc., to reduce the loss of mechanical efficiency , improve the service life and ensure the effect of work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

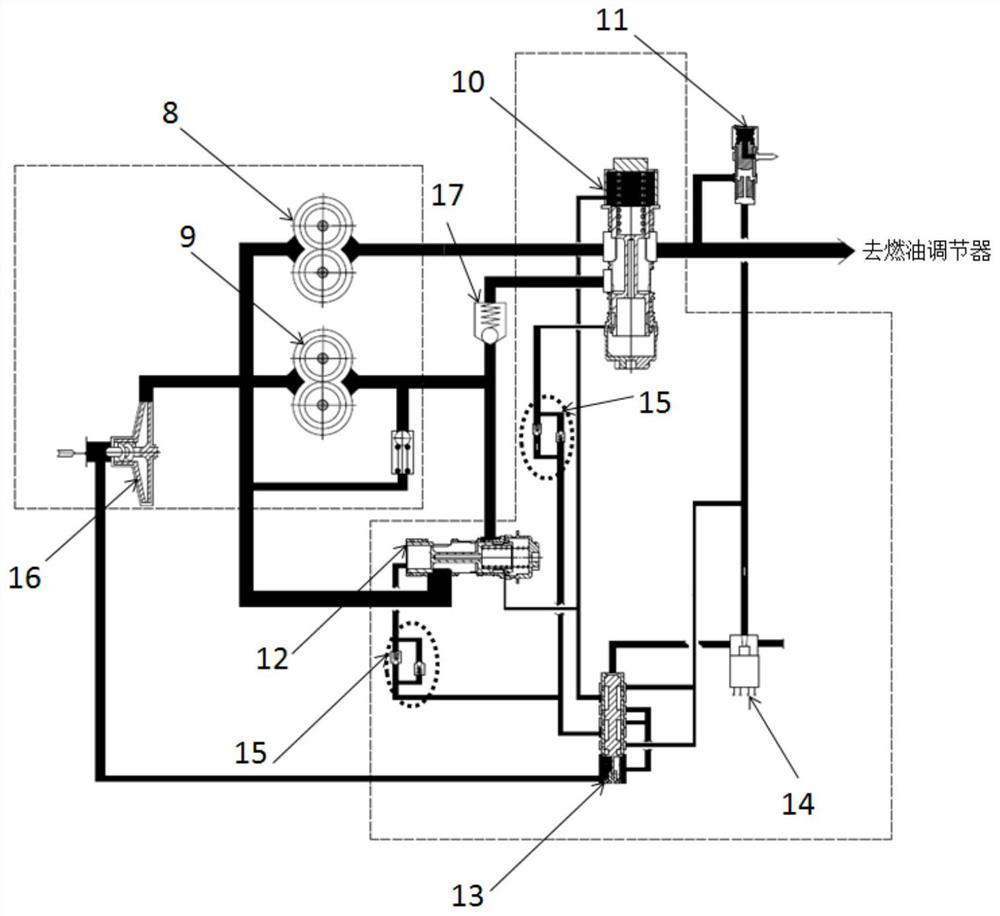

[0020] This embodiment provides an open-loop adjustment control device for oil supply switching of combined pumps, the open-loop adjustment control device includes a first gear pump 8, a second gear pump 9, a pump switching valve 10, and a constant pressure valve 11 , Oil return valve 12, switching valve 13 and pump switching solenoid valve 14.

[0021] Wherein, the first gear pump 8, the pump switching valve 10 and the constant pressure valve 11 are connected in sequence; the second gear pump 9, the pump switching valve 10 and the constant pressure valve 11 are connected in sequence; the second gear pump 9 is connected with the oil return valve 12; The oil return valve 12 returns to the front of the first gear pump 8 and the second gear pump 9; the conversion valve 13 communicates with the oil return valve 12, the pump switching valve 10 and the constant pressure valve 11 respectively; the pump switching solenoid valve 14 communicates with the constant pressure valve 11 , Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com