Evaporation method of linear evaporation sources and evaporation equipment

An evaporation source, linear technology, applied to the field of evaporation method and evaporation equipment of the online evaporation source, can solve the problems of mechanical aging of the evaporation system, low utilization rate of evaporation materials, long scanning distance of evaporation source, etc. The effect of shortening the scanning path, reducing the mechanical loss, and improving the use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Aiming at the problems in the prior art of low utilization rate of evaporation materials and mechanical aging of the evaporation system due to the long scanning distance of the evaporation source, an embodiment of the present invention provides an evaporation method for a linear evaporation source and evaporation equipment.

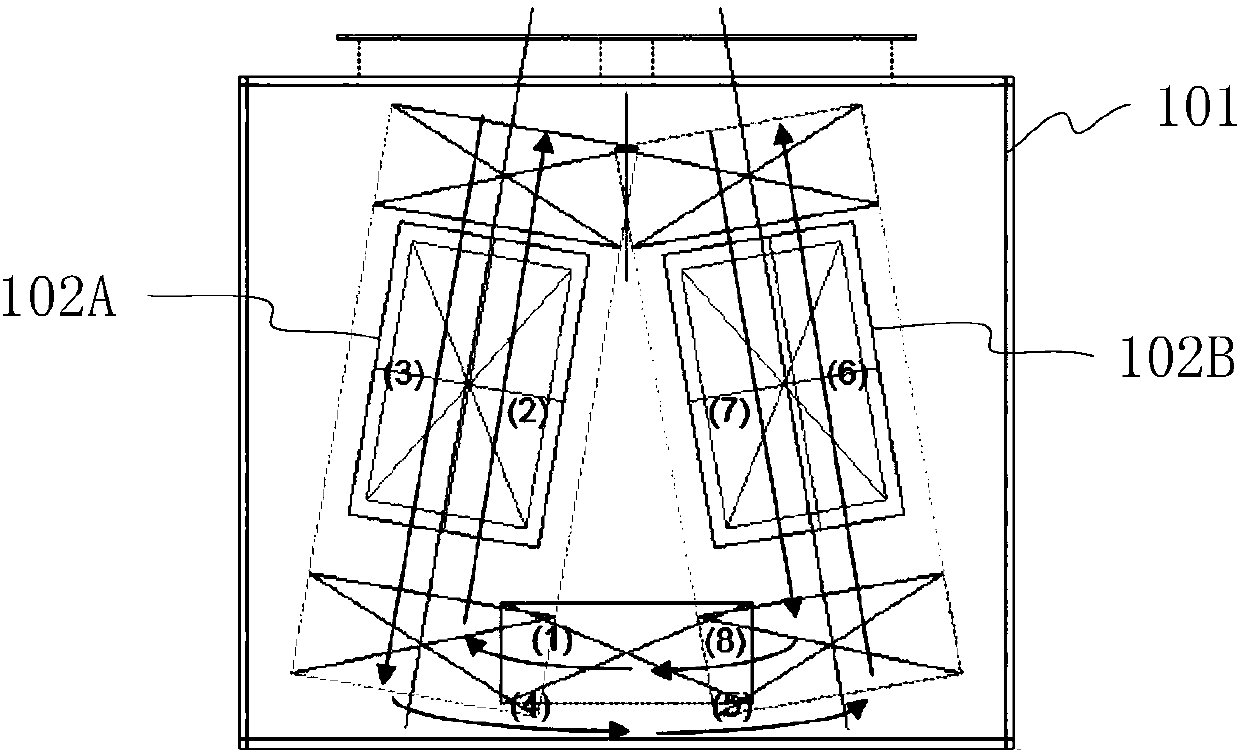

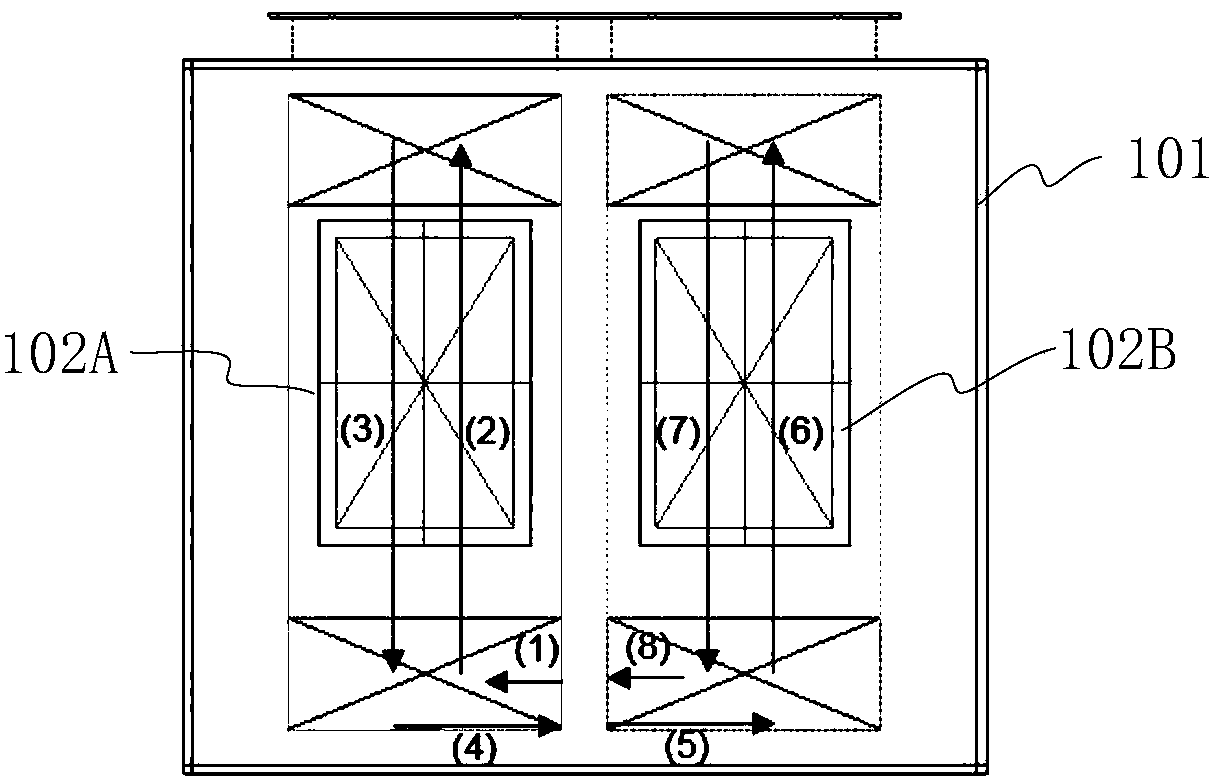

[0040] The specific implementation of a linear evaporation source evaporation method and evaporation equipment provided in the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The size and shape of each component in the drawings do not reflect the real scale, but are only intended to schematically illustrate the contents of the present invention.

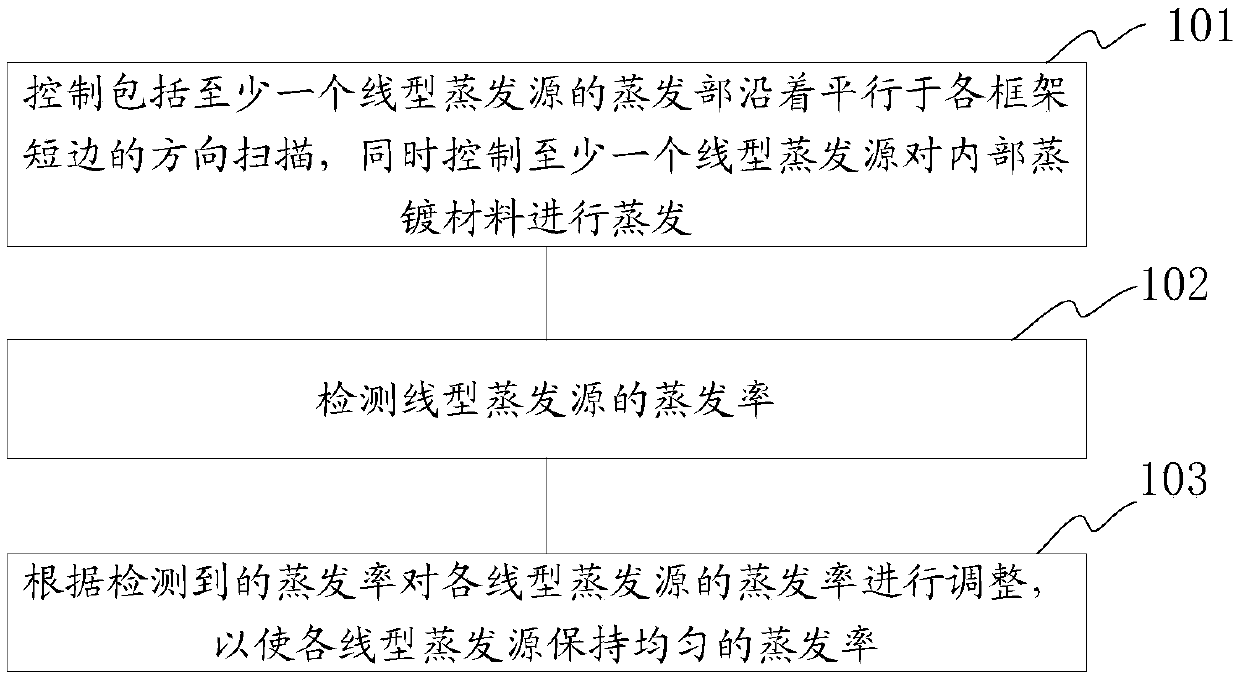

[0041] The embodiment of the present invention provides an evaporation method of a linear evaporation source, such as figure 1 shown, including:

[0042] S101. Control the evaporation part including at least one linear evaporation sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com