Biomass negative carbon emission power generation system and working method thereof

A biomass power generation and power generation system technology, applied in the chemical industry, can solve problems such as restricting the large-scale application of direct combustion power generation technology, and achieve the effects of improving biomass utilization, high economic value, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

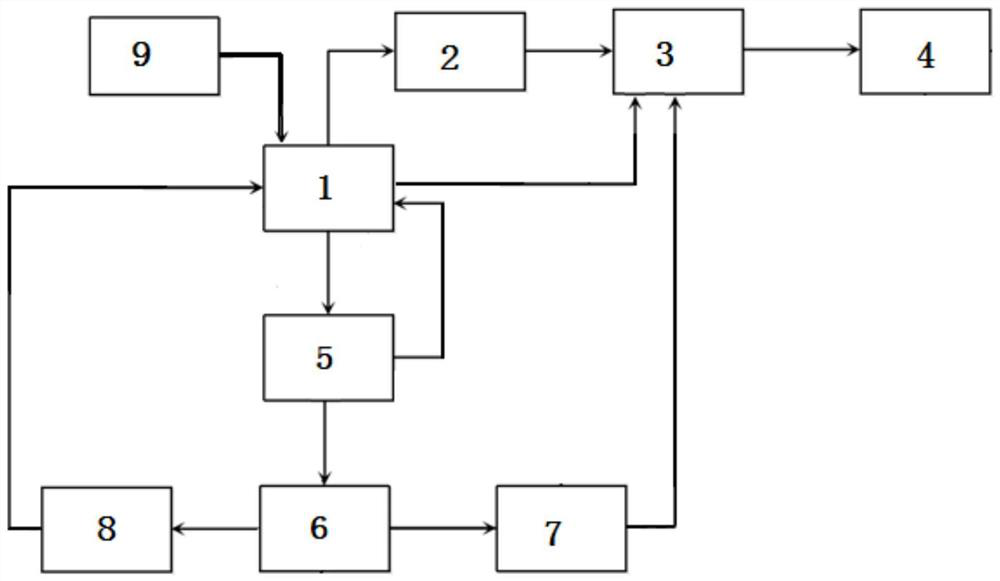

[0040] This embodiment provides a biomass negative carbon emission power generation system, such as figure 1 shown, including:

[0041] Biomass power generation unit 1;

[0042] The flue gas outlet of the biomass power generation unit 1 is connected to the inlet of the flue gas pretreatment unit 2, and the outlet of the flue gas pretreatment unit 2 is connected to the CO of the carbon nanotube unit 3 made of carbon dioxide. 2 Ingress connection;

[0043]The waste water outlet of the biomass power generation unit 1 is connected to the inlet of the water pretreatment unit 5, and the outlet of the water pretreatment unit 5 is connected to the water inlet of the electrolytic hydrogen production unit 6; the hydrogen outlet of the electrolytic hydrogen production unit 6 It is connected with the inlet of the hydrogen gas collection unit 7, and the outlet of the hydrogen gas collection unit 7 is connected with the hydrogen gas inlet of the carbon nanotube made of carbon dioxide unit...

Embodiment 2

[0054] This embodiment provides a working method utilizing the biomass negative carbon emission power generation system of Embodiment 1, including:

[0055] Biomass power generation is performed by the biomass power generation unit 1 to generate electric energy. During the power generation process, the flue gas and waste water generated by the biomass power generation unit 1 are processed and utilized through the following two routes:

[0056] The flue gas produced by the biomass power generation unit 1 enters the flue gas pretreatment unit 2 for treatment and then enters the carbon dioxide carbon nanotube unit 3, and the carbon nanotubes are prepared by electrochemical methods;

[0057] The waste water produced by the biomass power generation unit 1 enters the electrolytic hydrogen production unit 6 after being treated by the water pretreatment unit 5, and the hydrogen gas generated by the electrolytic hydrogen production unit 6 is collected by the hydrogen gas collection unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com