Wire winding support for bead wire winding machine

A bead wire and winding machine technology, which is applied in the field of bead wire processing, can solve the problems of easy bending of steel wire, small bending angle of steel wire, and bending of steel wire, etc., so as to increase the conveying effect, increase flexibility and improve conveying effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

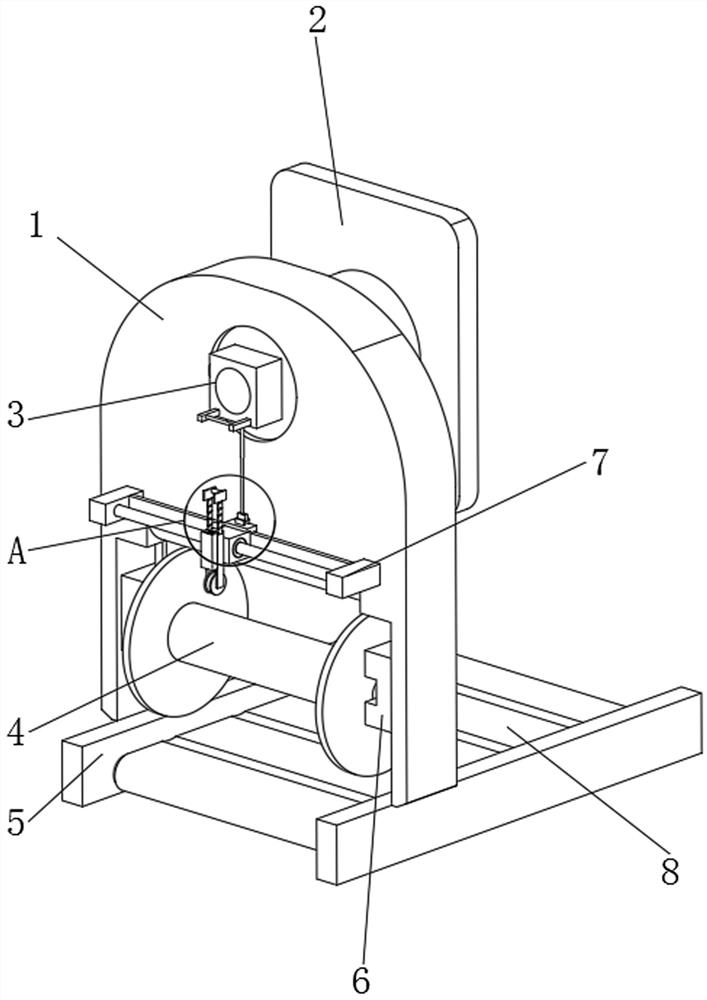

[0043] Such as Figure 1-Figure 13 As shown, the present invention provides a wire winding support for a bead wire winding machine, which includes a support plate 1, a conveyor belt fixing frame 5 is arranged under the support plate 1, a groove is opened under the support plate 1, and the support plate 1 The inner side of the lower groove is provided with a retracting wheel installation mechanism 6, the back of the support plate 1 is provided with a rear plate 2, the side of the support plate 1 away from the rear plate 2 is provided with a wiring guide assembly 7, and the outside of the support plate 1 is provided with a through hole , and a torsion mechanism 3 is arranged in the external through hole of the support plate 1;

[0044] The conveyor belt fixing frame 5 below the support plate 1 plays the role of fixing the conveyor belt 8, and the retracting wheel installation mechanism 6 in the groove below the support plate 1 can promote the workpiece retracting wheel 4, so tha...

Embodiment 2

[0058] Based on the wire winding support for a bead wire winding machine provided in the first embodiment of the present application, the second embodiment of the present application proposes another wire winding support for a bead wire winding machine. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0059] The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

[0060] Based on the first embodiment, the difference between the second embodiment and the first embodiment is that the second embodiment also has a winding wheel installation mechanism 6 .

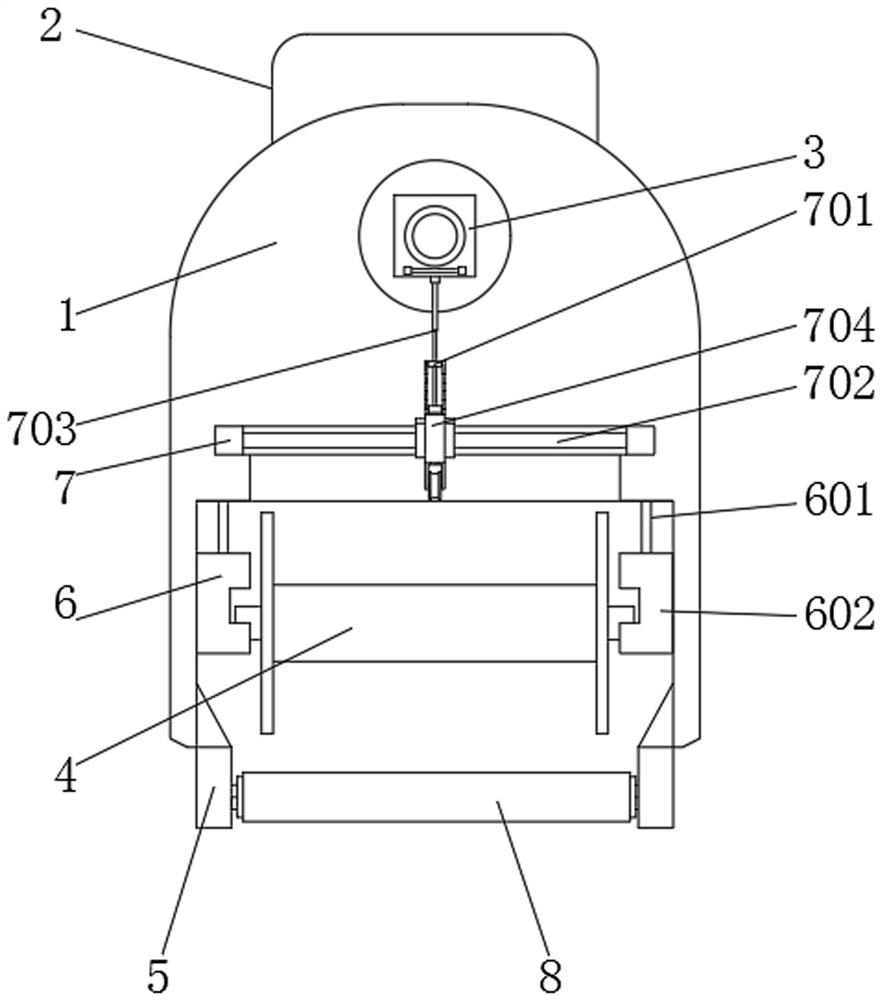

[0061] The retracting wheel installation mechanism 6 includes telescopic electric cylinders 601. There are two groups of telescopic electric cylinders 601. The two groups of telescopic electric cylinder...

Embodiment 3

[0066]Based on the wire winding support for a bead wire winding machine provided in the first embodiment of the present application, the third embodiment of the present application proposes another wire winding support for a bead wire winding machine. The third embodiment is only a preferred manner of the first embodiment, and the implementation of the third embodiment will not affect the independent implementation of the first embodiment.

[0067] The third embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

[0068] Based on the first embodiment, the difference between the third embodiment and the first embodiment is that the third embodiment also has a wiring guide assembly 7 .

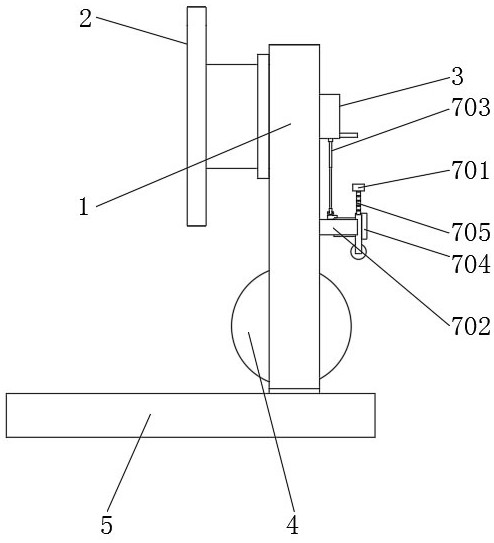

[0069] Specifically, the wiring guide assembly 7 includes a screw slide table 702, and a sliding base 707 is provided for sliding on the outside of the screw slide table 702, a guide seat 704 is provided on the outer wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com