Water replenishing device for new energy lead-acid battery

A technology of lead-acid battery and water replenishment device, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of labor-intensive and time-consuming, and achieve the effect of convenient water replenishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

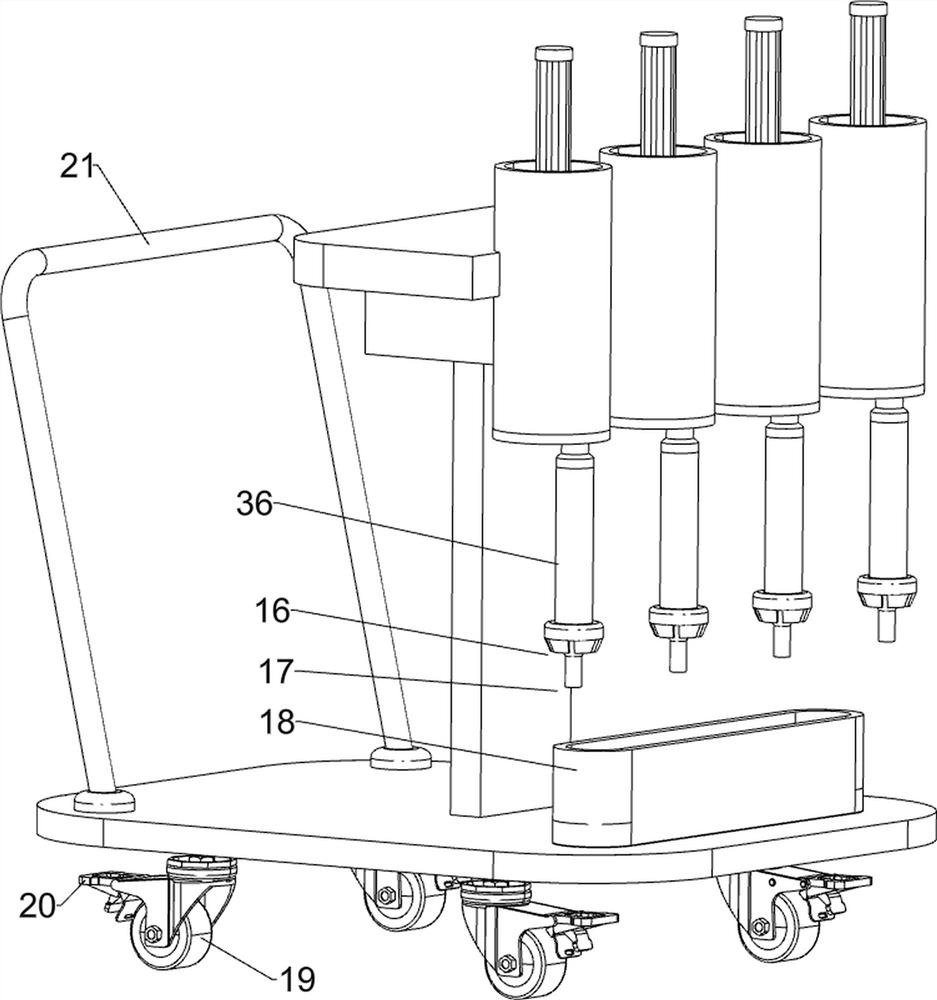

[0027] Such as figure 1 As shown, a new energy lead-acid battery water supply device includes a base frame 1, a support plate 2, an injection mechanism 3 and a drive mechanism 4, a support plate 2 is provided in the middle of the base frame 1, and an injection mechanism 3 is provided on the support plate 2 , The injection mechanism 3 is provided with a drive mechanism 4, and the injection mechanism 3 cooperates with the drive mechanism 4.

[0028] When the new energy lead-acid battery needs to be replenished with water, the staff will add a certain amount of water into the injection mechanism 3, and then the staff will start the driving mechanism 4, and the driving mechanism 4 will drive the injection mechanism 3 to move downward to inject water into the new energy lead. In the acid battery, the new energy lead-acid battery is replenished. After the new energy lead-acid battery is replenished, the staff controls the driving mechanism 4 to reverse, and the driving mechanism 4 s...

Embodiment 2

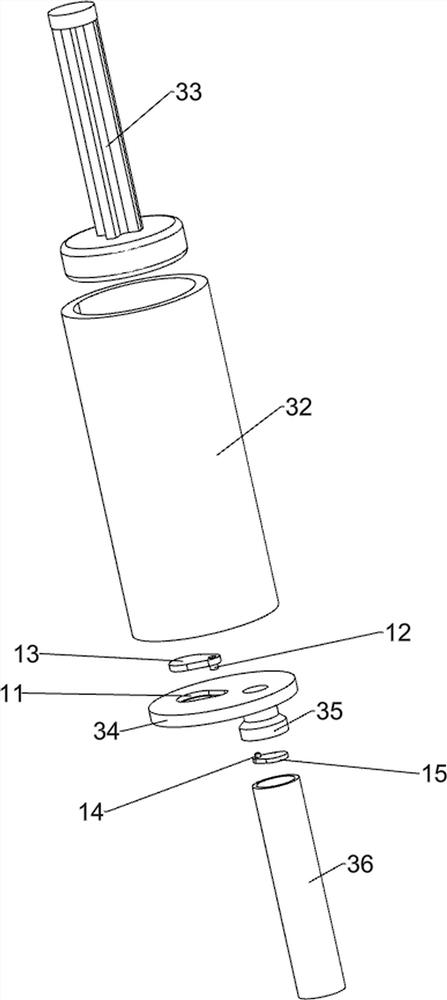

[0030] Such as figure 2 and image 3 As shown, on the basis of Embodiment 1, the injection mechanism 3 includes a fixed plate 31, a measuring cylinder 32, a piston assembly 33, a circular plate 34, a water outlet pipe 35 and a hose 36, and the support plate 2 is provided with a fixed plate 31, Four measuring cylinders 32 are evenly spaced on the right side of the fixed plate 31, and a piston assembly 33 is slidably arranged in the four measuring cylinders 32. The piston assembly 33 is composed of a piston and a piston rod. A piston is respectively arranged in the four measuring cylinders 32. Piston rod is all provided with on each piston, and four measuring cylinders 32 bottoms are all provided with disc 34, and four disc 34 right sides are all provided with outlet pipe 35, and four outlet pipe 35 bottom ends are all provided with flexible pipe 36.

[0031] When the new energy lead-acid battery needs to be replenished with water, the staff adds a certain amount of water into...

Embodiment 3

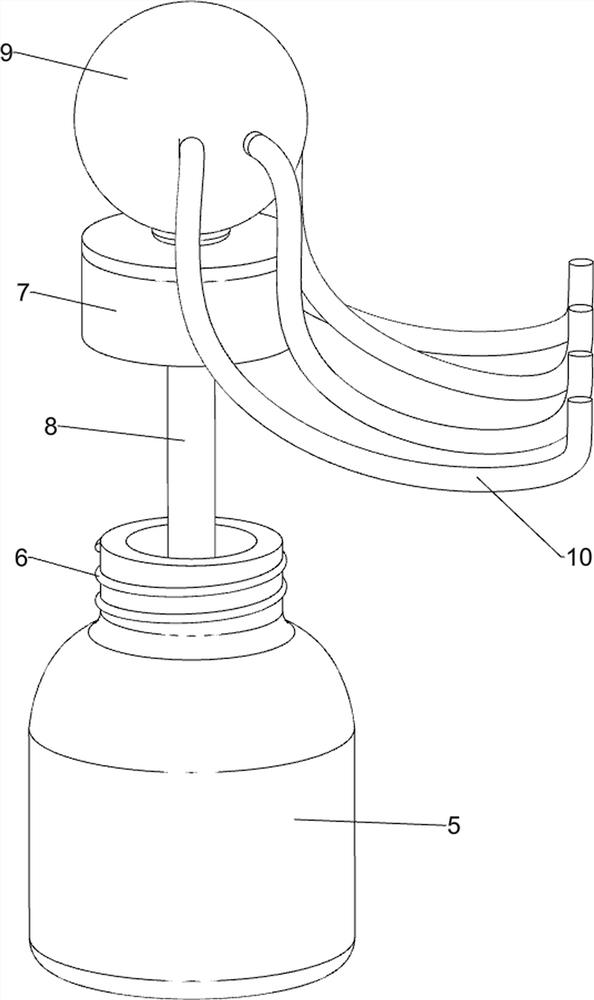

[0035] Such as Figure 4 , Figure 5 and Figure 6 As shown, it also includes a liquid storage bottle 5, a bottle cap 7, a water suction pipe 8 and a rubber liquid storage chamber 9. The left side of the bottom frame 1 is provided with a liquid storage bottle 5, and the liquid storage bottle 5 is provided with a thread 6, and the thread 6 is provided with a thread 6. Cooperate with bottle cap 7, bottle cap 7 is provided with water suction pipe 8, and the top of water suction pipe 8 is provided with rubber liquid storage cavity 9.

[0036]It also includes a connecting pipe 10, a first fixed pin 12, a first valve 13, a second fixed pin 14 and a second valve 15. The left sides of the four circular plates 34 are provided with special-shaped grooves 11, and the rubber liquid storage chamber 9 is evenly Four connecting pipes 10 are arranged at intervals, and the other ends of the four connecting pipes 10 are all connected to the special-shaped groove 11. The four circular plates 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com