Automatic diaphragm pressing and pole piece pressing group lamination carrying device

A carrier device and pole piece group technology, applied in the direction of sustainable manufacturing/processing, electrochemical generators, electrical components, etc., can solve problems affecting production capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

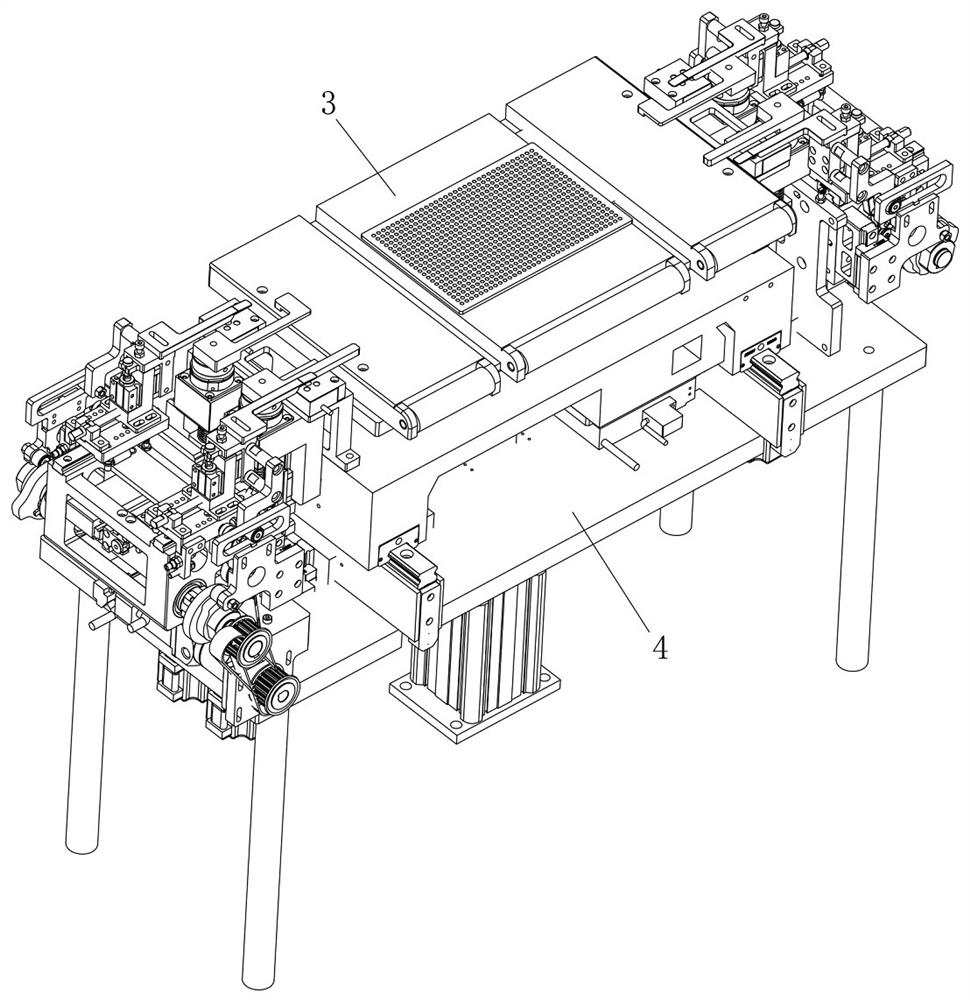

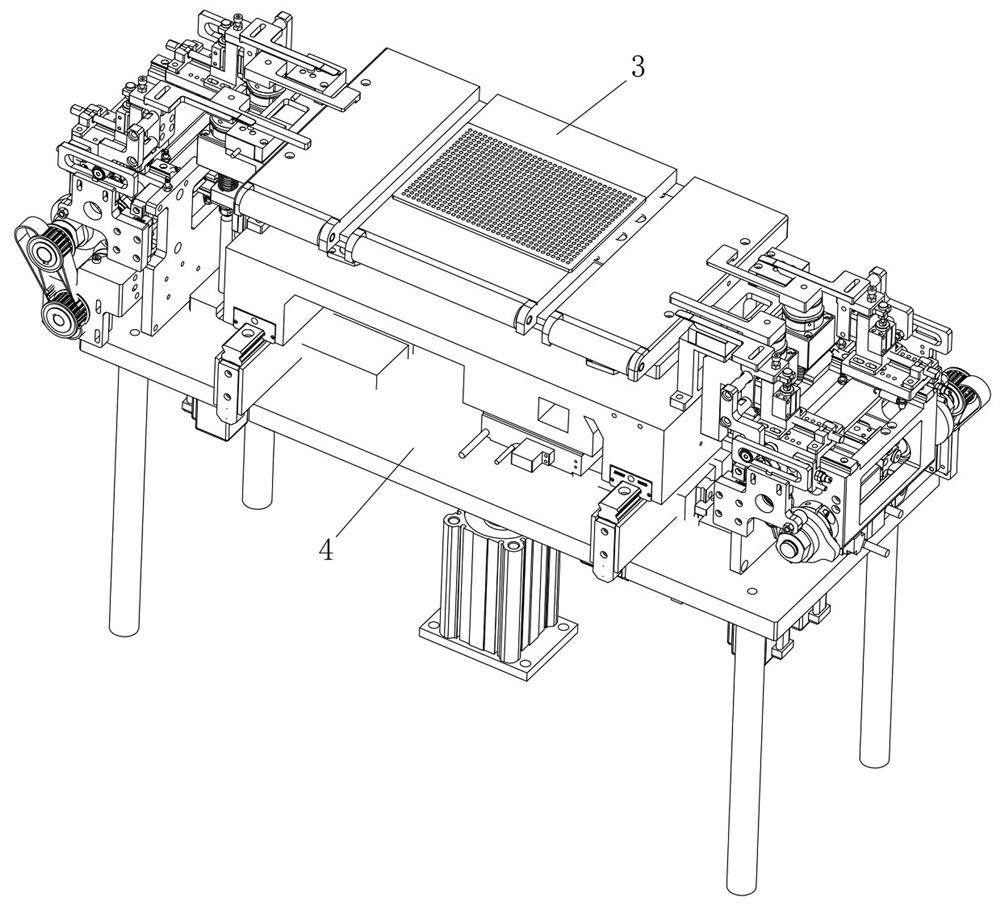

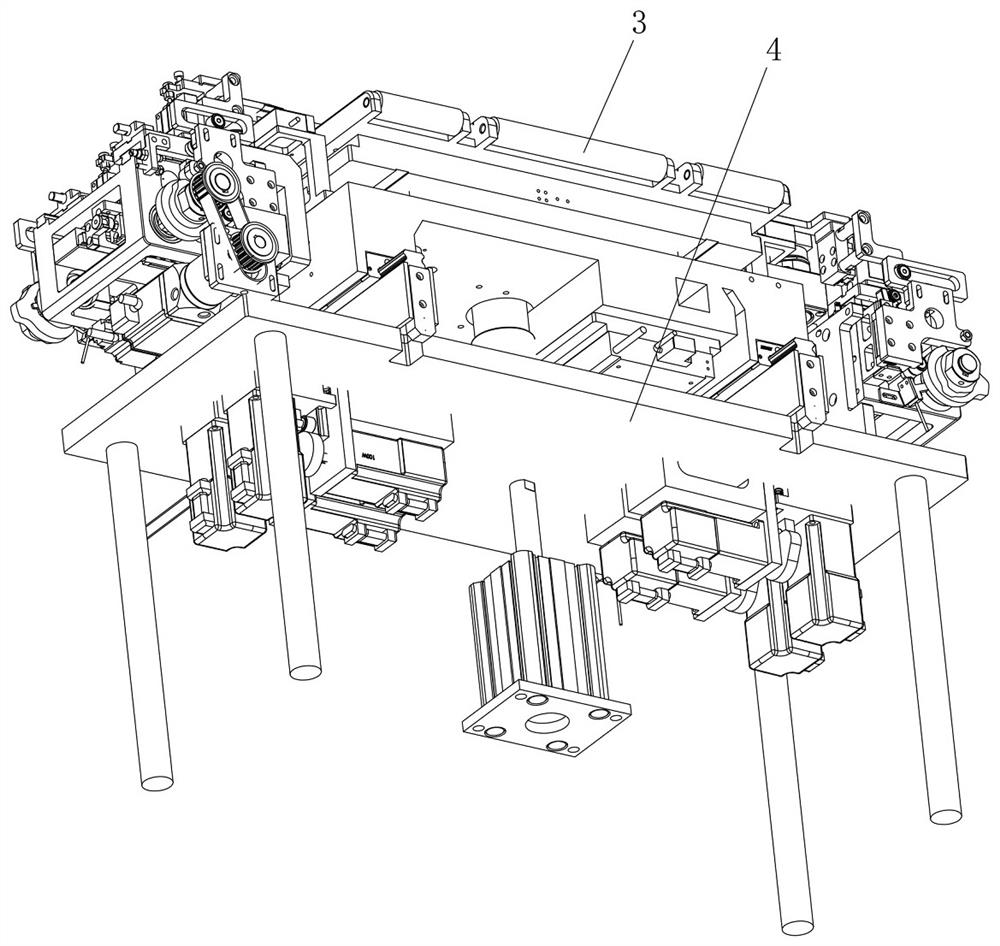

[0042] The present invention will be further described below in conjunction with accompanying drawing:

[0043] Such as Figure 1 to Figure 17 As shown, the technical solution adopted by the present invention is as follows: a lamination carrier device for automatically pressing diaphragms and pressing electrode groups, including a lamination platform 3 and a driving mechanism 4, wherein the above-mentioned driving mechanism 4 is horizontally arranged at the lamination station , which is provided with a platform space; the driving mechanism 4 includes a jacking assembly, a material cutting assembly and a film pressing assembly, the above lifting assembly is arranged below the platform space, and the material cutting assembly and film pressing assembly include two groups, which are respectively arranged in the platform space The left and right sides of the above-mentioned lamination platform 3 are movably arranged in the platform space, the lamination platform 3 includes a beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com