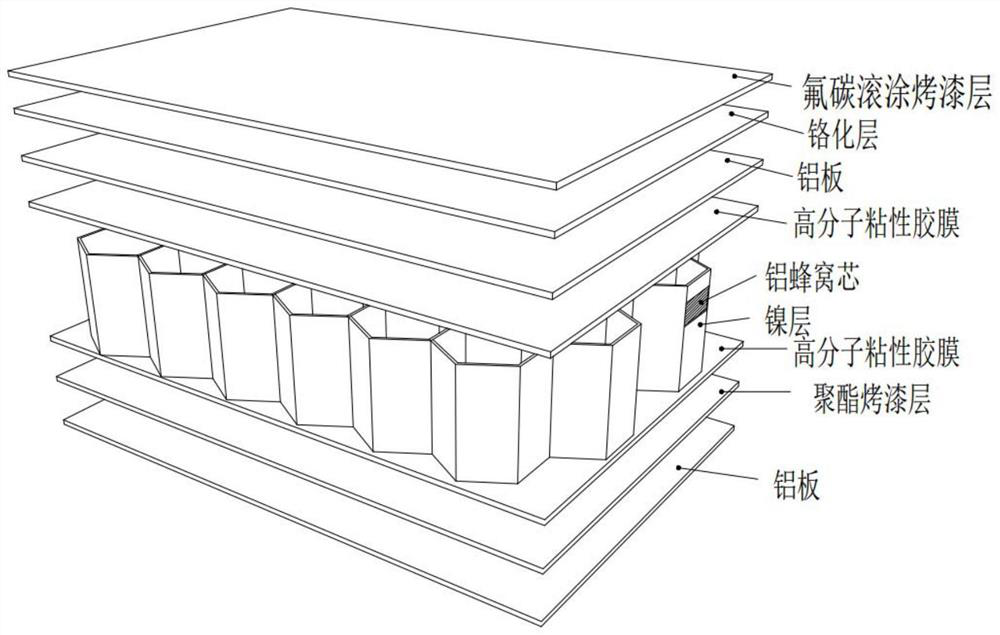

Honeycomb aluminum plate based on hot press molding and preparation process thereof

A technology of honeycomb aluminum plate and hot press forming, which is applied in metal material coating process, coating, construction, etc., can solve the problems of insufficient performance of honeycomb aluminum plate, and achieve the effect of avoiding glue cracking, simple process and enhanced performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] As an exterior wall honeycomb composite panel, the standard panel size is 1200mm x2400mm, and the thickness is: standard panel 20mm;

[0033] a) Cutting and surface cleaning: take two aluminum plates and aluminum honeycomb cores for size cutting, and after cutting, perform surface grinding and surface cleaning;

[0034] b) Laser cladding: take 100% pure nickel powder for drying treatment, preheat the inner and outer surfaces of the aluminum honeycomb core, the preheating temperature is 60°C, put the above nickel powder into the powder feeder, set the laser Cladding parameters, laser power 3000W, scanning speed 8mm / s, powder feeding rate 20g / min, spot diameter 5mm, lap rate 25%, nickel layer cladding on the inner and outer surfaces of the preheated aluminum honeycomb core, nickel The layer thickness is 5 μm;

[0035] c) Chromizing treatment: get an aluminum plate in step a), carry out chromizing treatment to one surface thereof, the steps of chromizing treatment are:

...

Embodiment 2

[0051] As an exterior wall honeycomb composite panel, the standard panel size is 1000mm x2000mm, and the thickness is: standard panel 20mm;

[0052] a) Cutting and surface cleaning: take two aluminum plates and aluminum honeycomb cores for size cutting, and after cutting, perform surface grinding and surface cleaning;

[0053] b) Laser cladding: take 100% pure nickel powder for drying treatment, preheat the inner and outer surfaces of the aluminum honeycomb core, the preheating temperature is 60°C, put the above nickel powder into the powder feeder, set the laser Cladding parameters, laser power 2500W, scanning speed 6mm / s, powder feeding rate 20g / min, spot diameter 3mm, lap rate 25%, nickel cladding on the inner and outer surfaces of the preheated aluminum honeycomb core, nickel The layer thickness is 8 μm;

[0054] c) Chromizing treatment: get an aluminum plate in step a), carry out chromizing treatment to one surface thereof, the steps of chromizing treatment are:

[0055...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com