Independent cleaning device and method for drafting shaft of flax drawing frame

A technology for cleaning devices and drafting shafts, applied in drafting equipment, spinning machines, textiles and papermaking, etc., can solve the problems of time-consuming and laborious, insufficient cleaning of drafting shafts, and restricted cleaning effect, etc., and achieve the overall structural design Simple and reasonable, superior cleaning effect, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0020] Example.

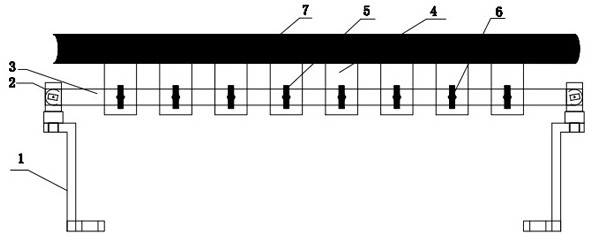

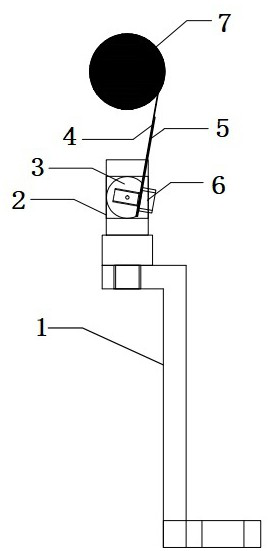

[0021] see Figure 1 to Figure 2 In this embodiment, the independent cleaning device for the drafting shaft of the linen drawing frame includes a shaft assembly 3, a cleaning sheet 4 and a spring sheet 5, and the shaft assembly 3 is arranged directly below each drafting shaft 7 of the drawing frame, Both the cleaning sheet 4 and the spring sheet 5 are plural, and the cleaning sheet 4 and the spring sheet 5 are fixed on the shaft assembly 3 , and the spring sheet 5 is attached to the outside of the cleaning sheet 4 .

[0022] The spring sheet 5 in this embodiment is made of stainless steel spring sheet; the cleaning sheet 4 is made of plastic or copper sheet; it is selected according to the actual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com