Preparation method of biomass photosynthetic hydrogen production mixed flora

A technology of mixing flora and biomass, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of ineffective hydrogen production by photofermentation, lack of application prospects, low hydrogen production efficiency, etc. Low cost, wide application prospect, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

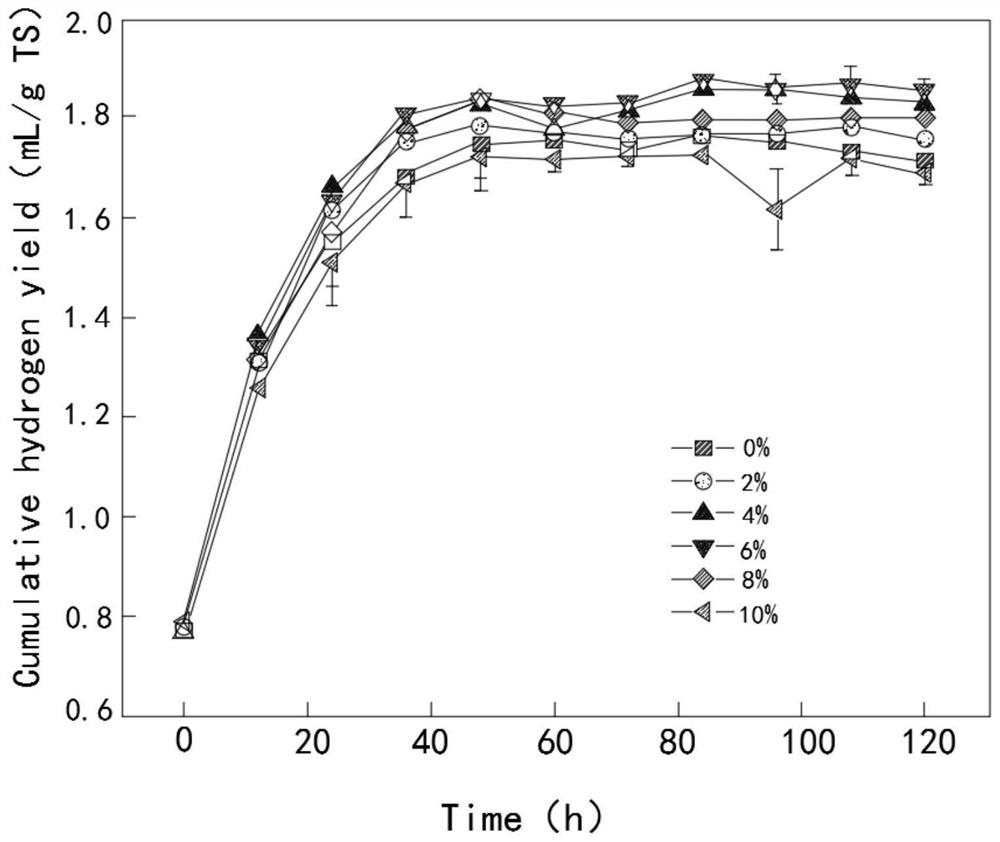

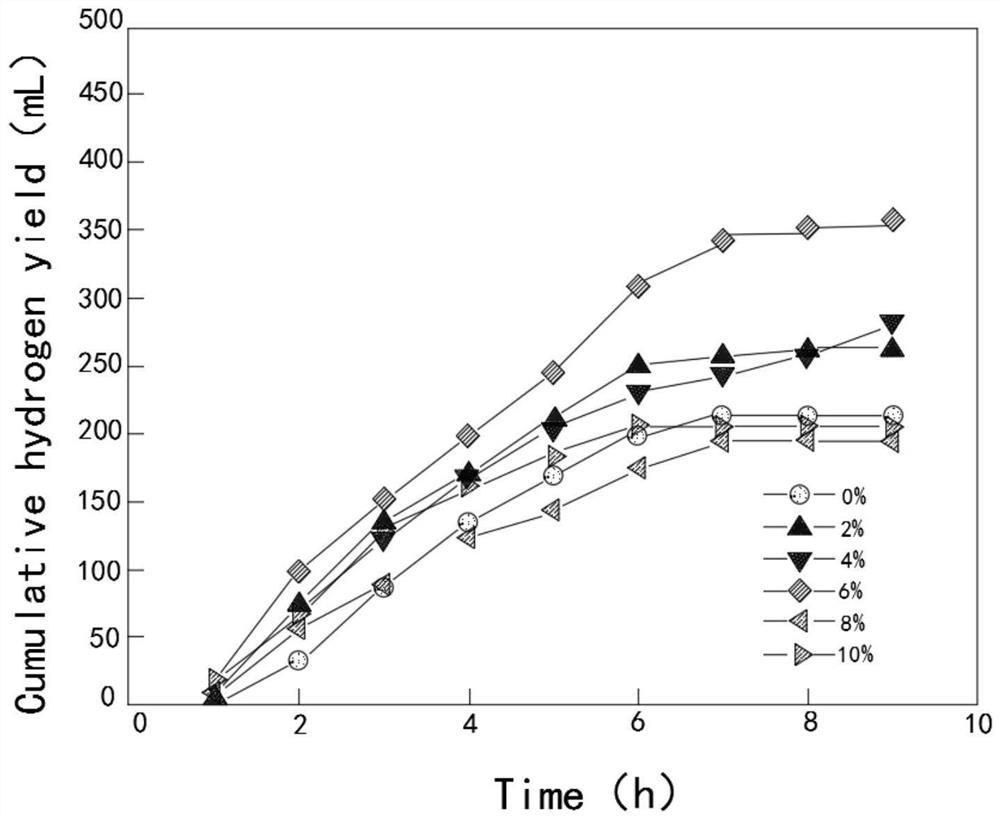

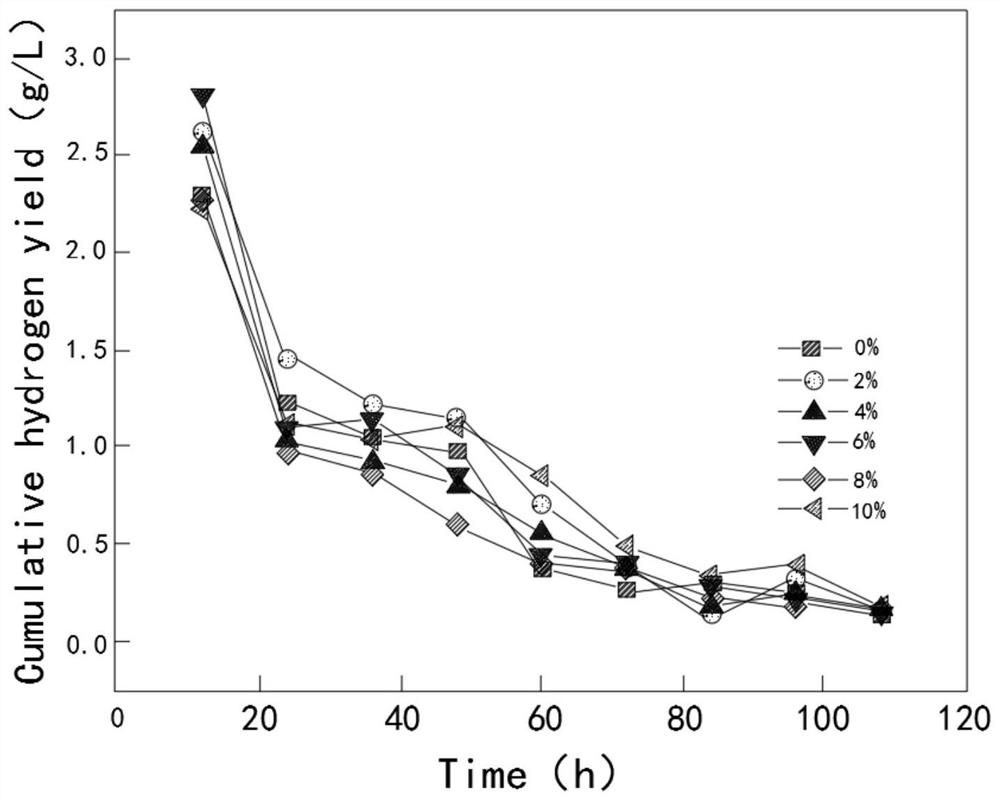

[0025] like Figure 1-3 As shown, the preparation method of the biomass photosynthetic hydrogen-hydrogenation mixed gel of the present invention includes the following preparation steps:

[0026] S1, preparing bacterial growth medium: including the following components and densities thereof: ammonium chloride (1 g · L -1 ), Sodium bicarbonate (2g · L -1 ), Yeast paste (1g · L -1 ), Hydrogen phosphate (0.2g · L -1 ), Sodium acetate (4g · L -1 ), Magnesium sulfate (0.2g · L -1 ) And sodium chloride (2g · L -1 );

[0027] S2, amplified bacteria: Novel photosynthetic bacteria with Hau-M1 photosynthetic bacteria to co-cultivate hydrogen bacteria, adding growth medium in anaerobic sealing culture vessel and co-cultivating hydrogen, placed under suitable conditions Culture amplification;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com