A kind of auxiliary equipment for coating vacuum cavity welding for low-e glass production

A vacuum chamber and auxiliary equipment technology, applied in glass production, climate change adaptation, window/door improvement, etc., can solve problems such as hidden dangers of construction safety for workers, splashes in high-temperature melting areas, and affecting the welding effect of materials, etc. Improve the welding effect, improve the spray width, and the effect of strong connection tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

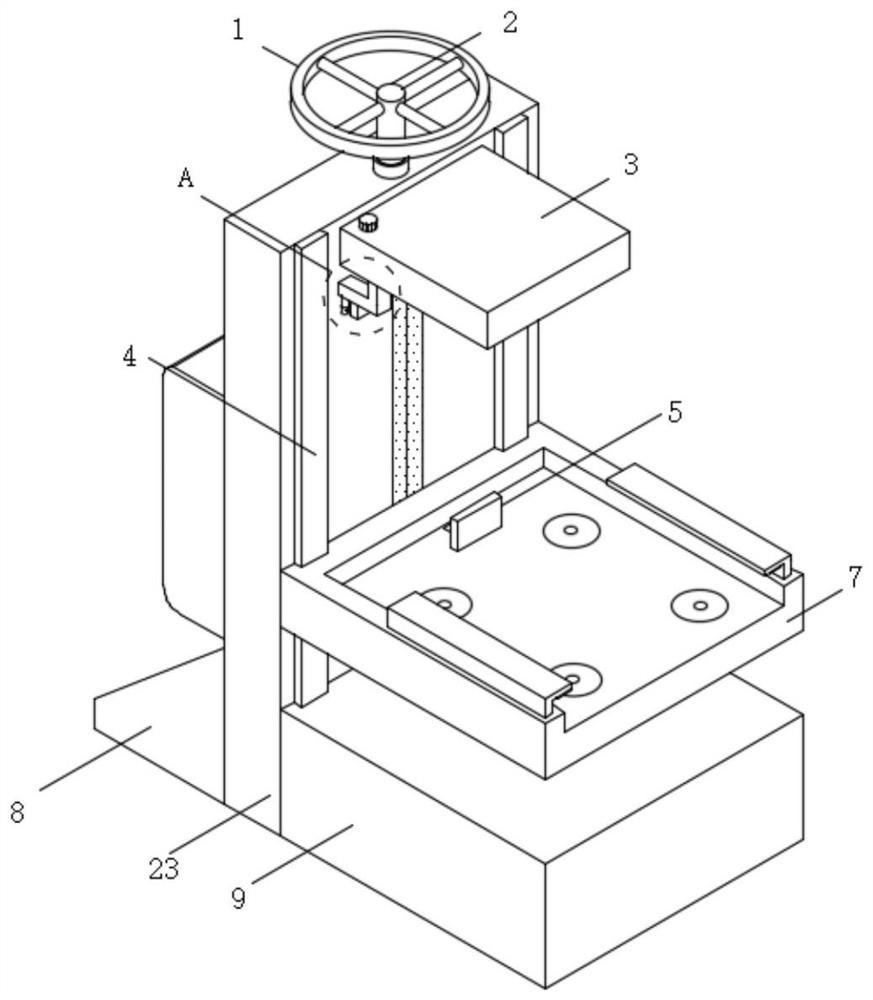

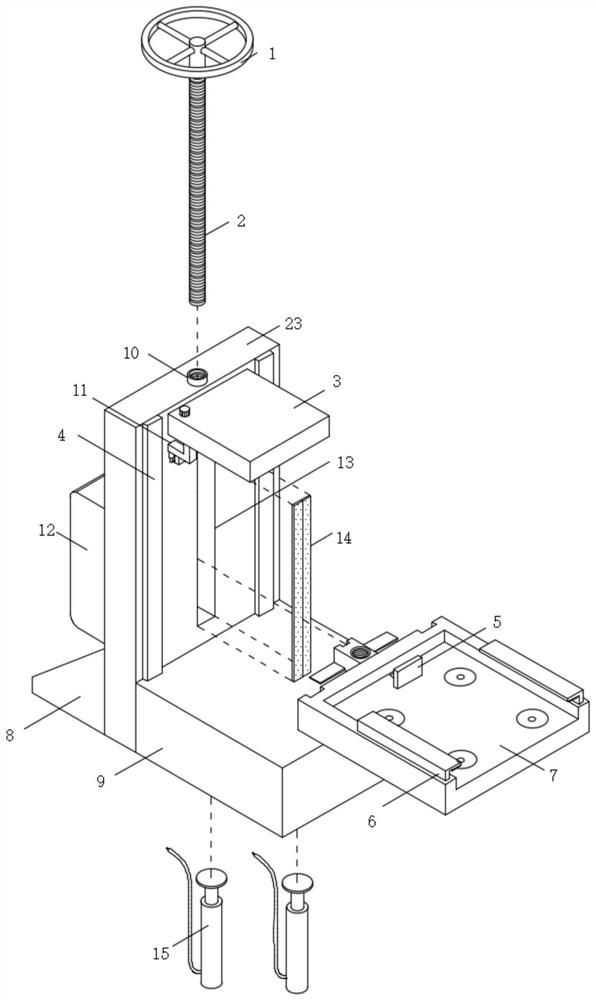

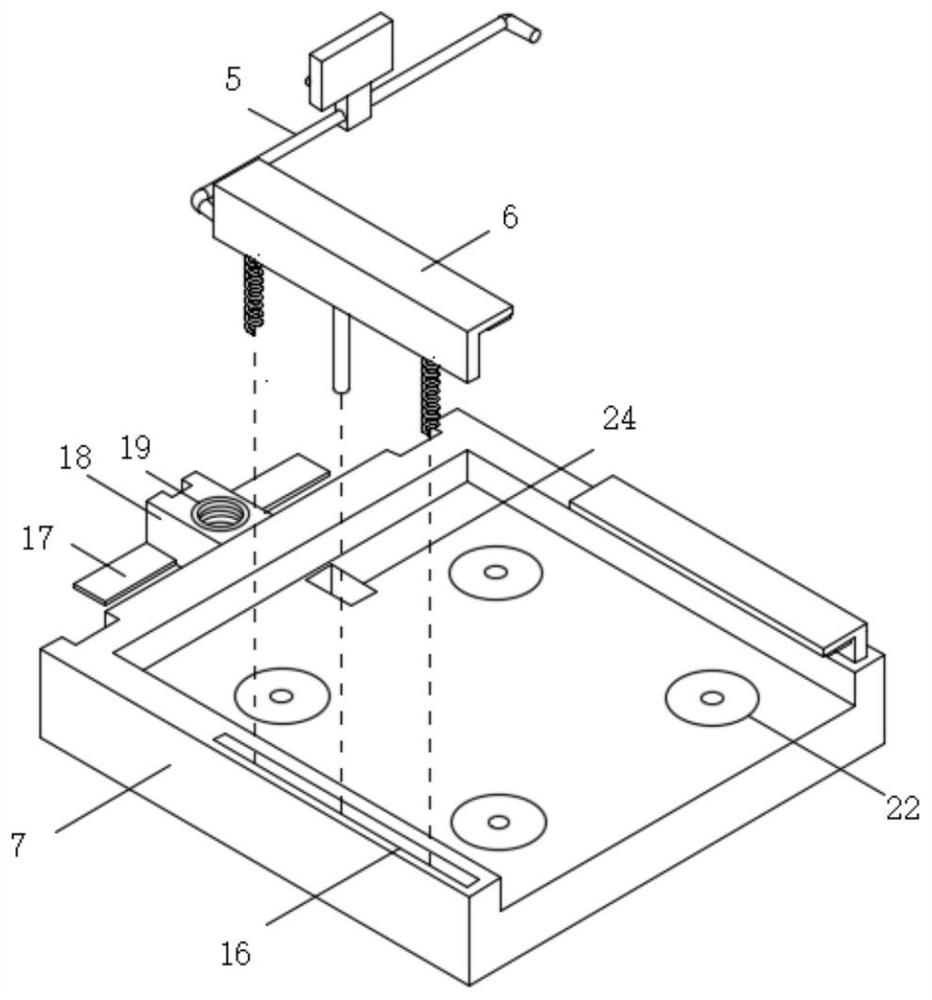

[0032] see Figure 1-8, the present invention provides a technical solution: a coating vacuum cavity welding auxiliary equipment for LOW-E glass production, including a glass mounting seat 7 and a main mounting frame 23, the two outer walls of the main mounting frame 23 are respectively fixed and installed on both sides There are a side support seat 8 and a base 9 , the upper part of the side support seat 8 and the base 9 are respectively provided with an air bag 12 and a material storage assembly 3 on the outer surface of the main mounting frame 23 , and an air tube is provided on the top of the air bag 12 20. The top of the air duct 20 is fixedly installed with a square duct 11, one end of the square duct 11 is fixedly connected to the bottom surface of the material storage assembly 3, and the bottom of the square duct 11 is provided with a thermal control assembly 21 for the square duct 11. Air flow control in conduit 11;

[0033] The thermal control assembly 21 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com