Device and method for drawing and forming thin-walled capillary tube assisted by ultrasonic vibration with controllable temperature and speed

An ultrasonic vibration and capillary technology, applied in the direction of wire drawing dies, etc., can solve the problems of small wall thickness, achieve the effect of small wall thickness, prevent fracture failure, and reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as there is no conflict with each other.

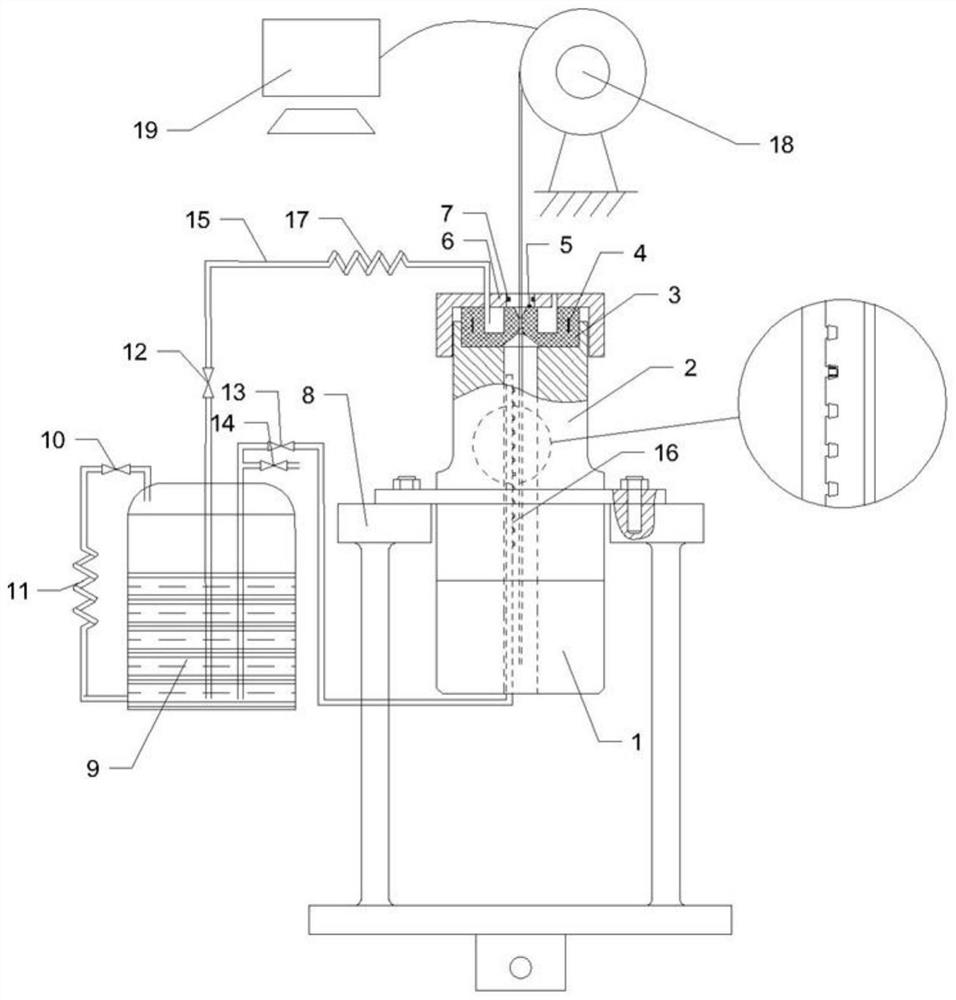

[0032] The embodiment of the present invention provides a temperature-controlled and speed-controlled ultrasonic vibration-assisted thin-walled capillary drawing and forming device, such as figure 1 As shown, it includes a bracket 8, an ultrasonic component, a temperature control component, a speed control component and a computer 19, wherein:

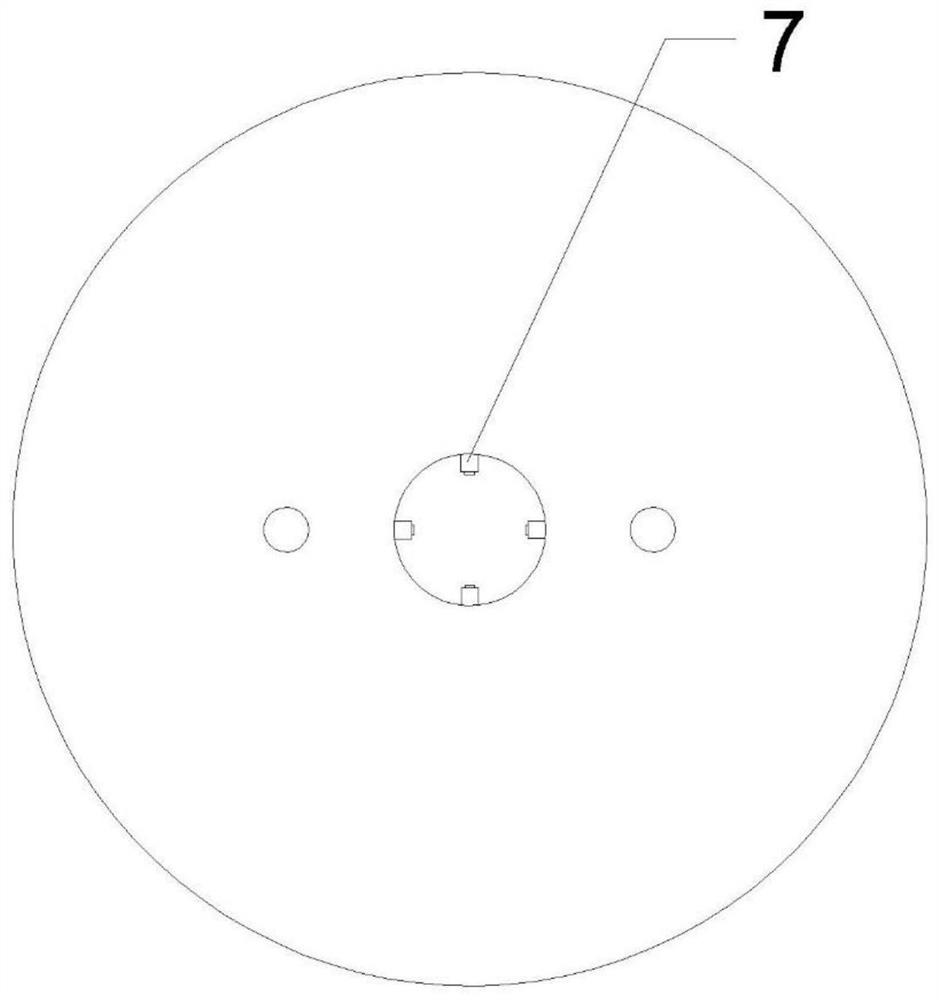

[0033] Described ultrasonic assembly comprises ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com