Efficient solid waste treatment device

A solid waste and treatment device technology, which is applied in the field of high-efficiency solid waste treatment devices, can solve problems such as insufficient pressure, easy jamming, and incomplete crushing, and achieve the effects of improving efficiency, avoiding jamming, and protecting devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

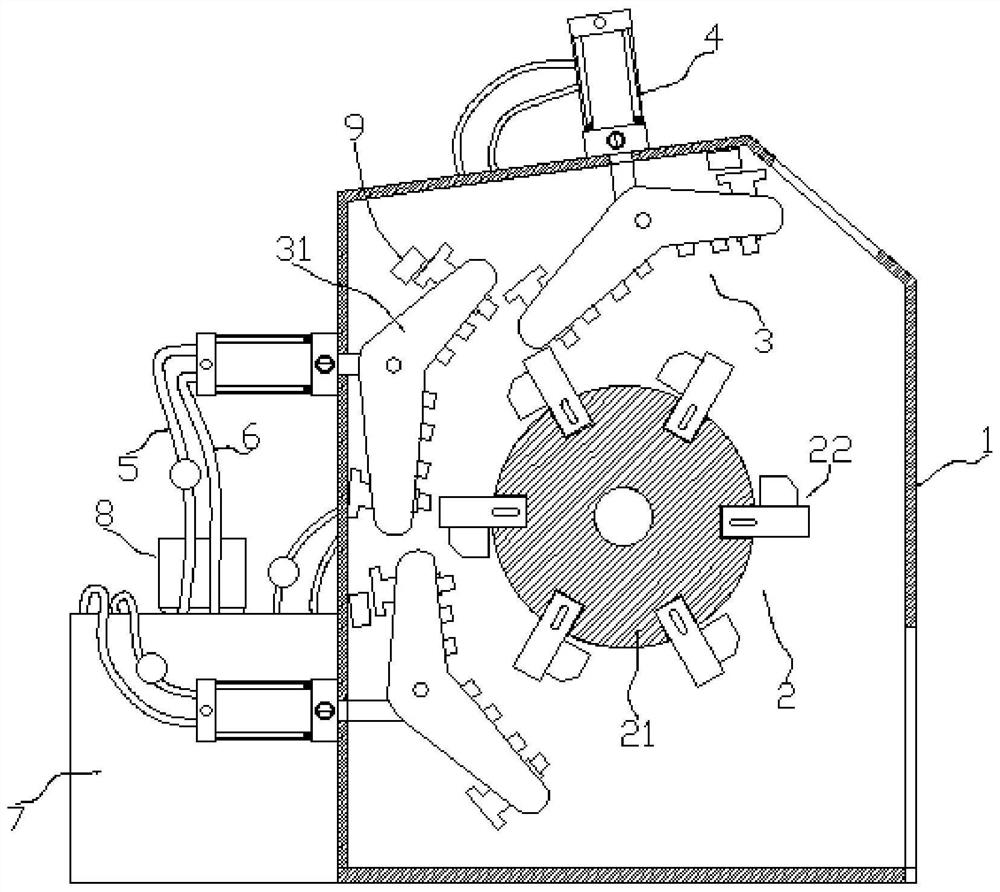

[0024] Such as figure 1 As shown, a high-efficiency solid waste treatment device of the present invention includes a crushing box 1, a central pressing roller 2 rotatably arranged in the crushing box 1, and at least one set of variable pressure loads arranged outside the central pressing roller 2. As for the component 3, a material inlet is opened on the crushing box 1, and the variable pressure loading component 3 located at the front end is arranged at the material inlet. The solid waste is guided and arranged between the variable pressure loading assembly 3 and the central pressing roller 2 through the channel, driven by the turning of the central pressing roller 2, and the variable pressure loading assembly 3 cooperates with the central pressing roller 2 to crush solid waste .

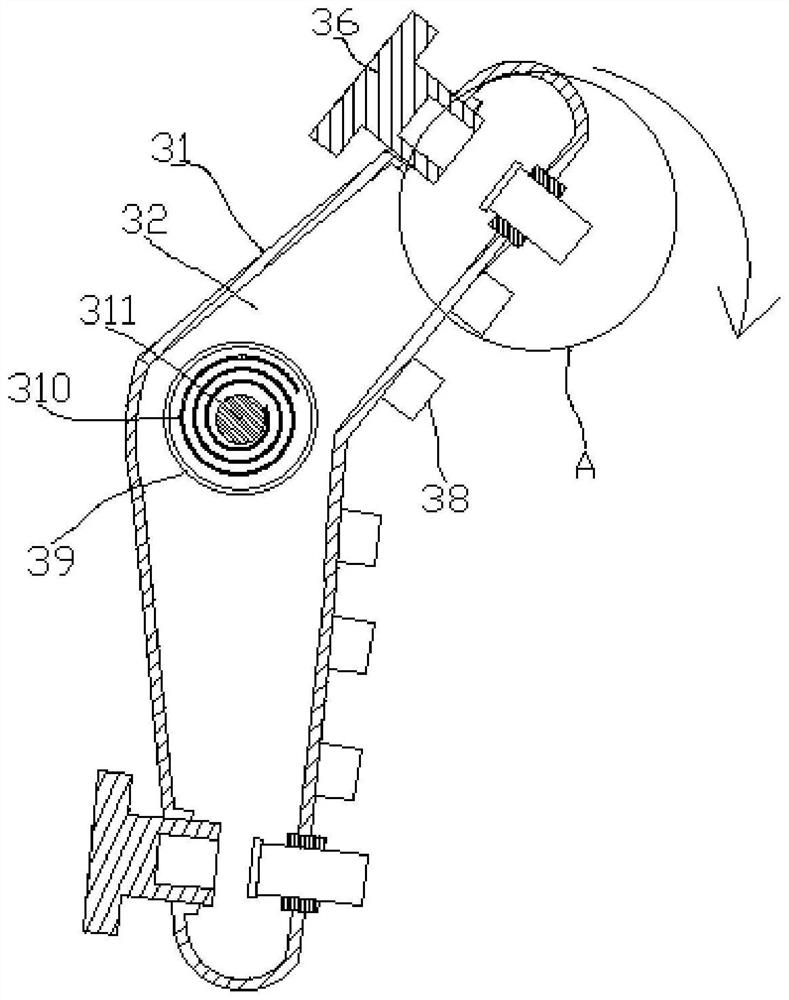

[0025] Specifically, such as figure 2 As shown, the variable pressure loading assembly 3 includes a pressure block 31, which is in the shape of a bent strip. The pressure block 31 is arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com