Anti-precipitation device for producing water-based paint on outer wall surface

A water-based paint and anti-precipitation technology, applied in the directions of transportation and packaging, dissolution, mixer, etc., can solve the problems that the quality of the paint cannot reach the best state, affect the mixing effect of the paint, and affect the use effect of the paint, etc. The effect of reducing precipitation and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

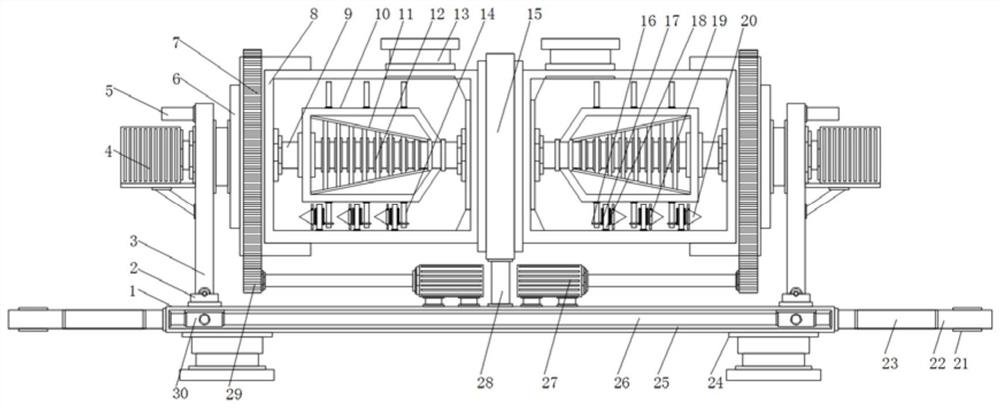

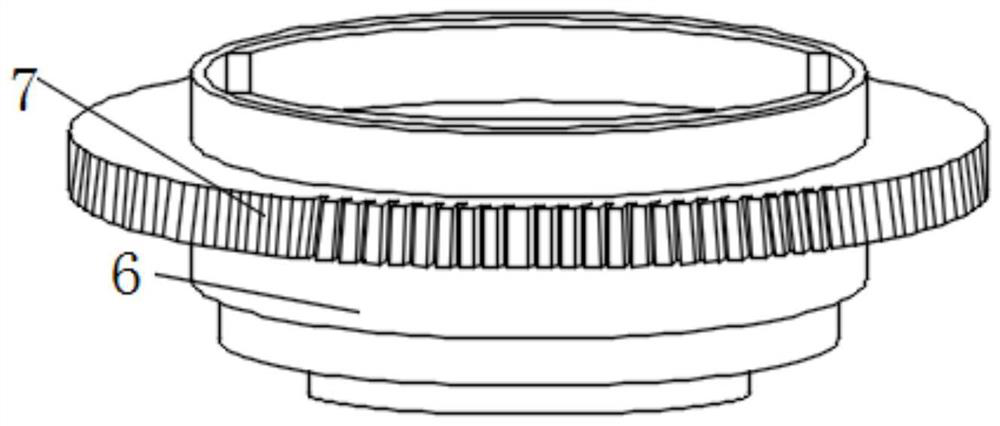

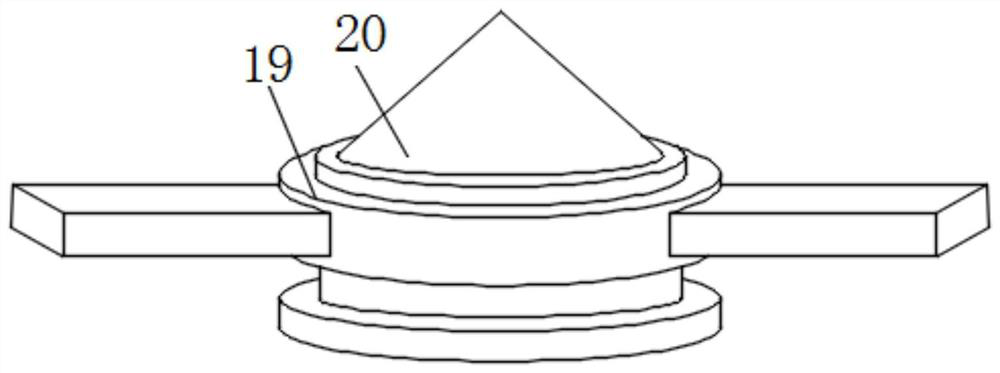

[0036] Embodiment one, with reference to Figure 1-7 , an anti-sedimentation device for the production of water-based paint on exterior walls, comprising a fuselage body 1 and support legs 24, a moving seat 2 is slidably installed on both sides of the top surface of the fuselage body 1, and the middle position of the top surface of the moving seat 2 is rotated by a rotating shaft Support rod 3 is installed, and the top position of one side surface of support rod 3 is fixedly installed with fixed rod 5, and the top position of support rod 3 other side surface is rotatably connected with turntable 6, and the outer periphery of turntable 6 is fixedly installed with gear ring 7, and one side of turntable 6 The middle position of the surface is clamped with a stirring tank 8, and the inner middle position of the stirring tank 8 is provided with a stirring paddle 9, one end of the stirring paddle 9 runs through the stirring tank 8 and one side of the support rod 3 is connected with t...

Embodiment 2

[0037] Embodiment two, refer to figure 1 , the middle position inside the fuselage body 1 is provided with a moving chamber 25, the middle position inside the moving chamber 25 is provided with a slide bar 26, the outer periphery of the slide bar 26 is sleeved with a positioning cylinder 30, and one end of the positioning cylinder 30 runs through one side of the fuselage body 1 and is connected to the mobile The seat 2 is welded in phase, and the completed mixing tank 8 can be easily moved out by moving the positioning cylinder 30, which is convenient for subsequent cleaning operations.

Embodiment 3

[0038] Embodiment three, refer to figure 1 with Image 6 , the stirring tank 8 is provided with two groups in total, and the positions between the two groups of stirring tanks 8 are sealed and clamped with a connecting pipe 15, and the middle position of the bottom surface of the connecting pipe 15 is fixedly installed with a welding plate 28, and the stirring tank 8 can be connected through the connecting pipe 15. connect them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com