Dust falling and collecting device for thermosetting powder coating production

A technology of thermosetting powder and dust collection device, which is applied in the direction of combination device, separation method, and dispersed particle separation, etc., which can solve the problems of quality degradation of thermosetting powder coatings, affect the quality of thermosetting powder coatings, and affect the use of thermosetting powder coatings, etc., and achieve improved dust reduction the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

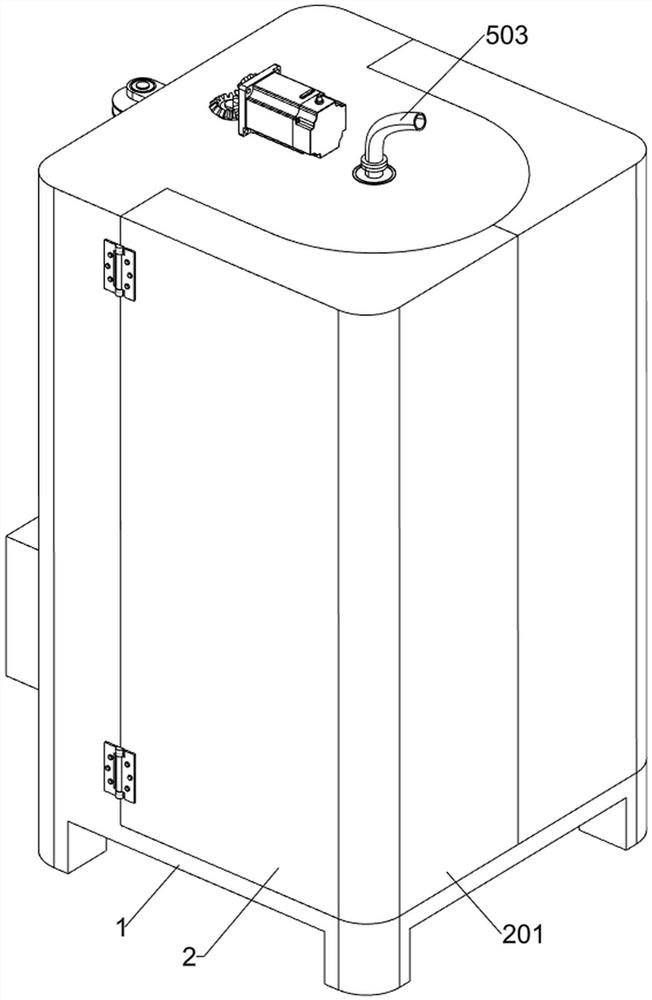

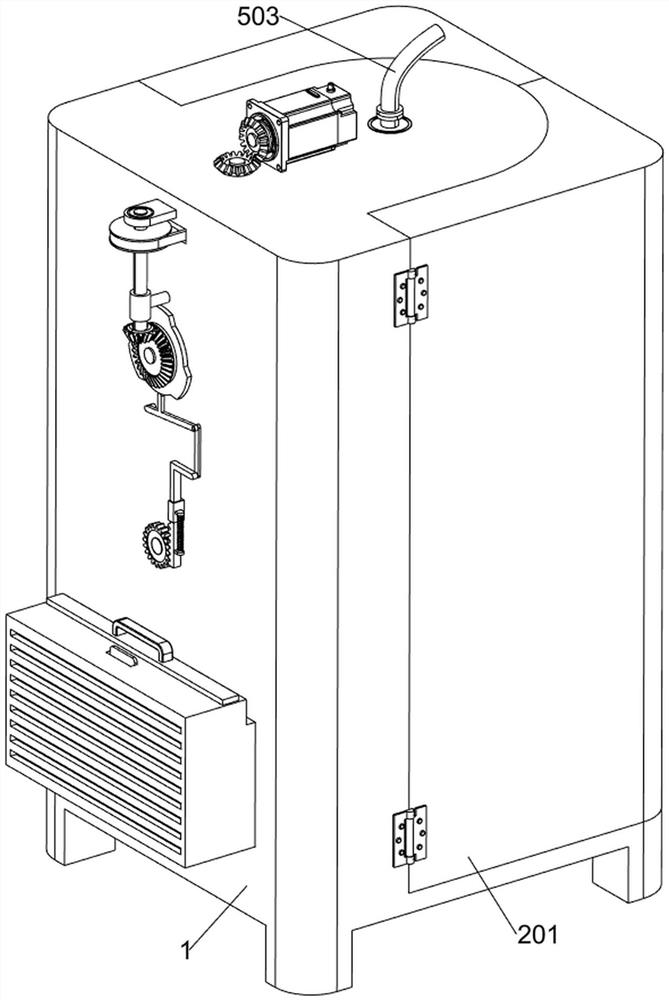

[0035] A thermosetting powder coating production dust dust collector, such as Figure 1 - Figure 10 Shown, comprises a housing 1, opening and closing assembly 2, the dust collecting assembly 3, a fixed frame 4, dust spray nozzle assembly 5 and 6, a shutter assembly housing 12, the housing 1 is provided in the lower left dust collection assembly for filtering dust collector 3, the housing 1 is provided with a fixed top frame 4, provided on the fixed frame 4 dust assembly 5 is provided with four evenly spaced for atomizing spray dust on dust assembly 5 nozzle 6.

[0036] Opening and closing assembly 2 comprises a rotary gate 201, an electric push rod 202 and the first pawl 203, the front and rear sides of the left portion of the housing 1 are provided with rotary revolving door 201, 201 contact with each revolving door, inside the housing 1 upper left front and rear symmetrical with electric push rod 202, between the top of the left side electric push rod telescoping rod 202 adjacent...

Embodiment 2

[0041] On the basis of Example 1, such as Figure 11 - Figure 16 As shown, there is a drive assembly 7, the drive assembly 7 includes a pulley 701, a first axis 702, a double slot transmission wheel 703, a servo motor 704, a first cone 705, a first belt 706, a second axis 707, The second leather belt 708, the second cone gear 709, the contact wheel 710 and the third cone gear 711, the upper left rotation of the housing 1 is provided with the first axis 702, and the lower portion of the first shaft 702 is provided with a double groove transmission wheel 703, housing 1 The top left side is provided with a servo motor 704. When the servo motor 704 is activated, the atomizing nozzle 6 can be rotated, so that the water mist can be uniformly sprayed inside the housing 1, and the servo motor 704 is located on the right side of the first shaft 702, The first cone 705 is provided on the output shaft of the servo motor 704 and the first rotating shaft 702, and the first tapered gear 705 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com