Method and device for judging particle defect source in semiconductor manufacturing process

A particle defect and process technology technology, used in semiconductor/solid-state device testing/measurement, image data processing, instruments, etc., can solve the problems of low efficiency and error in particle defect source judgment, improve timeliness and avoid human errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The metal wire digging structure and method proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

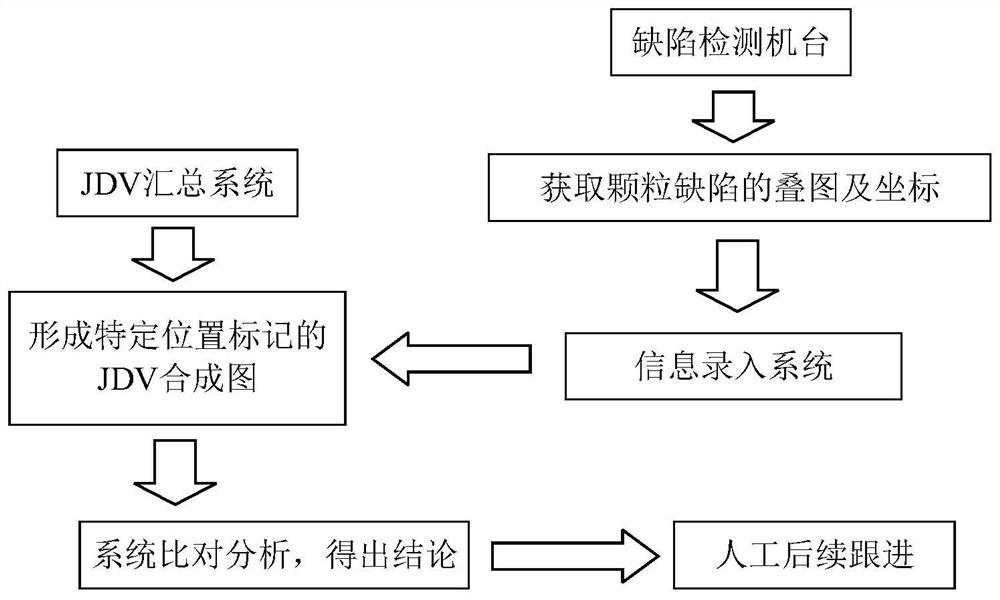

[0027] Please refer to Figure 1 to Figure 3 , an embodiment of the present invention provides a method for judging the source of particle defects in a semiconductor manufacturing process, including:

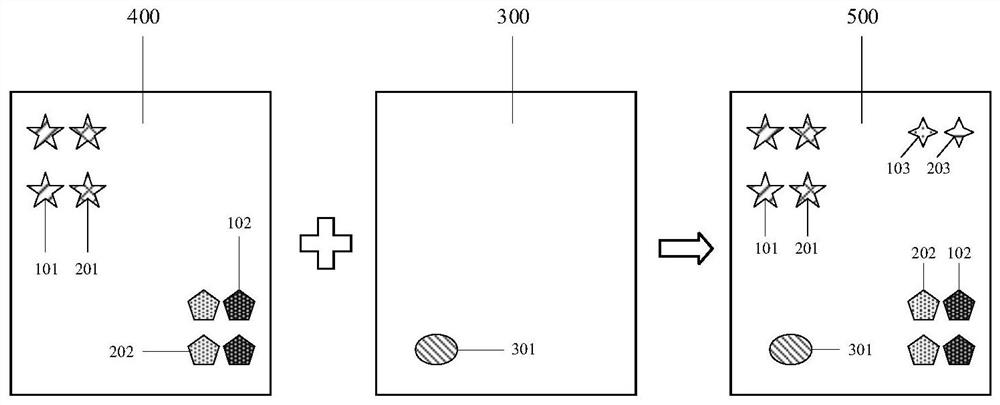

[0028] Step 710, please refer to figure 1 , in the wafer photolithography process, the JDV pattern 100 of the NMOS region and the JDV pattern 200 of the PMOS region of the photoresist layer in the ion implantation region are extracted, respectively compared w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap