Variable universe fuzzy PID extrusion type 3D printer slurry extrusion control method and device

A 3D printer and control device technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as unstable extrusion pressure, achieve rapid extrusion pressure stability, improve printing and forming accuracy, and improve The effect of robust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

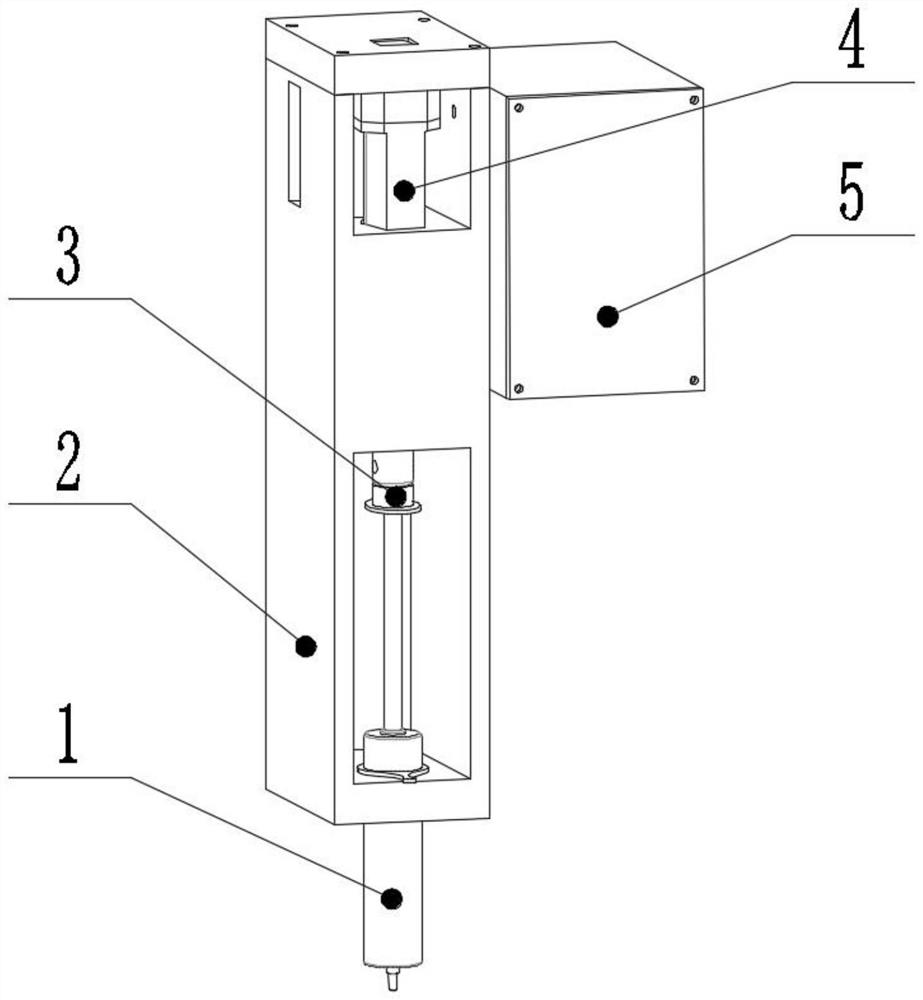

[0033] Such as figure 1 As shown, a variable universe fuzzy PID extrusion type 3D printer slurry extrusion control device is characterized in that it includes a base 2, a stepping motor push rod 4 coaxially arranged in the base, and a syringe 1. A load cell 3 is arranged between the stepping electric push rod and the injector, a control cabinet 5 is installed on the right side of the base, and a control unit is arranged in the control cabinet, and the control unit is respectively connected with the stepping motor pusher. The rod and the load cell are connected, the stepping electric push rod, the load cell and the syringe are from top to bottom and the three are coaxial to ensure that the stepping electric push rod will not be disturbed by other directions during the extrusion process.

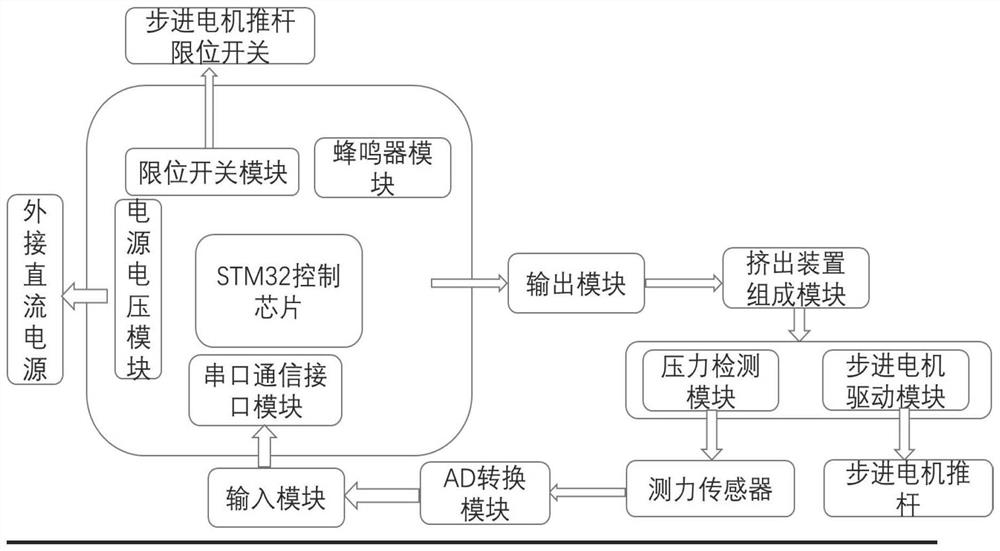

[0034] Such as figure 2 As shown, the control unit includes a sequentially connected STM32 control module, an output module, a pressure detection module, a stepper motor drive module, an A / D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com