Hydrogen long-distance transportation system and combined process

A combined process and conveying system technology, applied in the fields of hydrogen production and hydrogenation, can solve the problems of high equipment requirements, small transportation volume and low transportation efficiency, and achieve the effects of good safety, easy transportation and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0029] According to a preferred embodiment of the present invention, the forward conveying system and the reverse conveying system are mutually independent and controlled separately.

[0030] The present invention also provides a hydrogen long-distance transport combined process, which is carried out by using the hydrogen long-distance transport system, including the following steps:

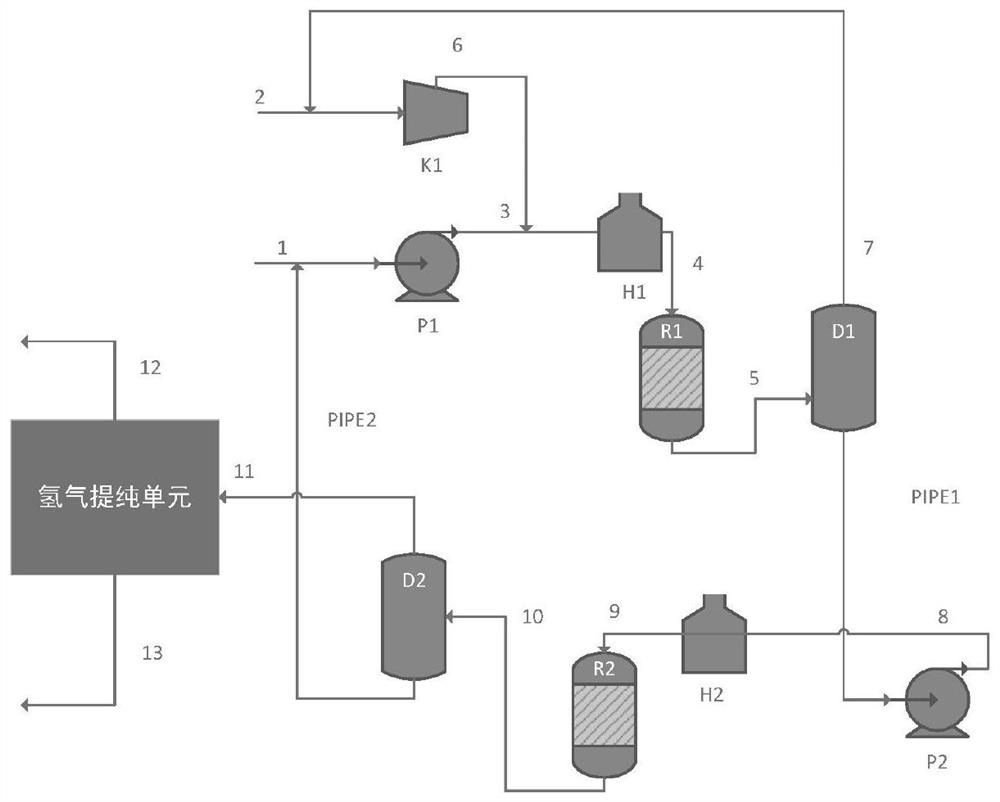

[0031] (i) The hydrogen-poor solvent 1 is fed into the hydrogen-poor solvent feed pump P1 by the hydrogen-poor solvent feed line to boost the pressure and sent into the hydrogen gas compressor K1 compressed by the hydrogen gas feed line The hydrogen 2 from the hydrogen producing area is mixed, and then sent to the hydrogenation reactor R1 after being heated by the hydrogen-poor solvent feeding furnace H1;

[0032](ii) The hydrogen-poor solvent after boosting and heating and the hydrogen 2 from the hydrogen production area after compression and heating are subjected to a catalytic hydrogenation s...

Embodiment 1

[0042] Such as figure 1 As shown, the present invention provides a long-distance hydrogen transportation process and system, the process and system comprising: the hydrogen-poor solvent 1 is fed into the hydrogen-poor solvent feed pump P1 by the hydrogen-poor solvent feed line to boost the pressure mixed with the hydrogen gas 2 compressed by the hydrogen compressor K1 from the hydrogen gas feed pipeline, and sent to the hydrogenation reactor R1 after being heated by the hydrogen-poor solvent feed heating furnace H1 , carry out catalytic hydrogenation saturation reaction in described hydrogenation reactor R1, obtain the first reaction product I5 and enter described 1# separating tank D1 to carry out gas-liquid separation, the first gas phase 7 obtained by top separation passes through described first gas phase The discharge pipeline returns to the inlet of the hydrogen compressor K1, and the hydrogen-rich solvent separated at the bottom is transported to the destination through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com