Intelligent parking pile lifting system capable of sensing width of vehicle body

A lifting system and parking pile technology, applied in the field of parking piles, can solve problems such as scratching, inability to park at will, and parking piles occupying parking spaces, and achieve the effect of increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

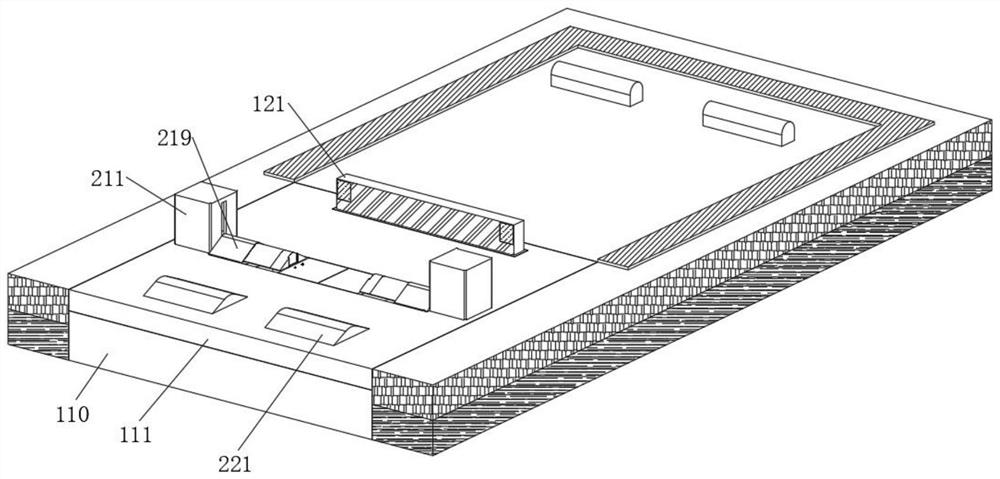

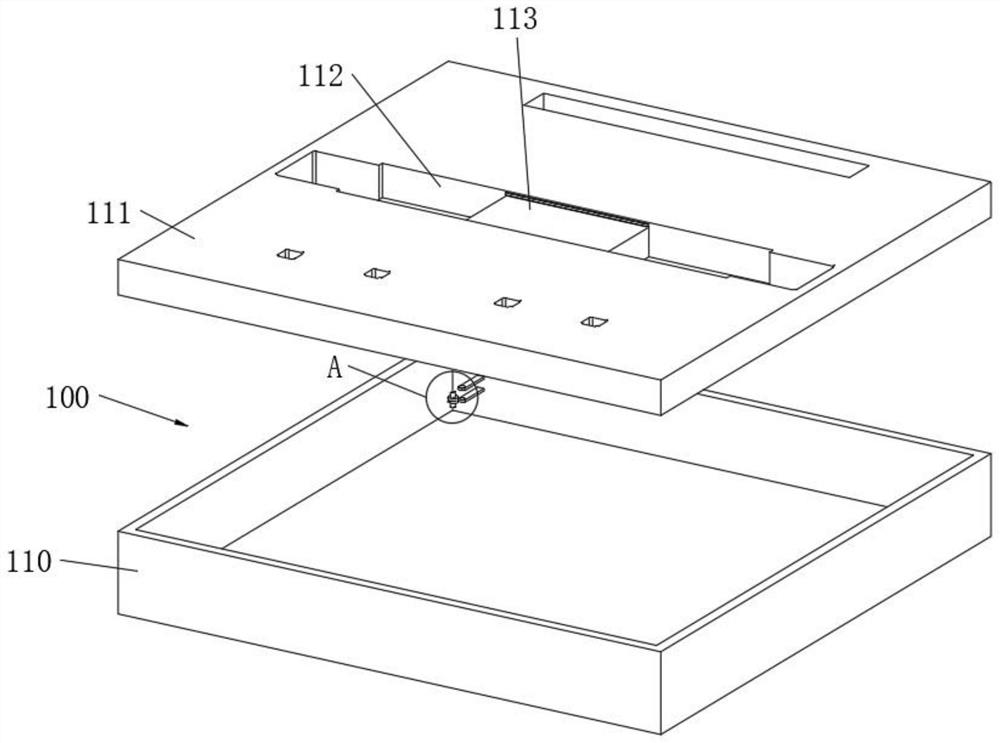

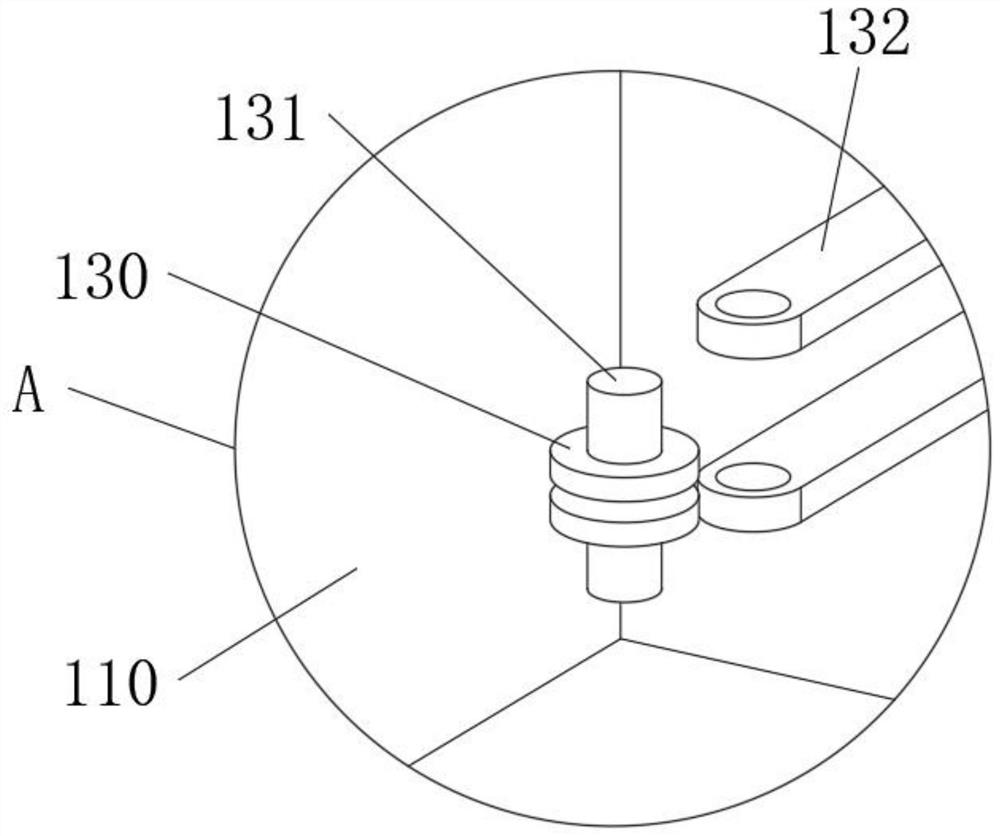

[0048] see Figure 1-Figure 9 As shown, an intelligent parking pile lifting system with vehicle body width sensing is provided, including a mounting device 100 and a lifting device 200 disposed in the mounting device 100, the mounting device 100 includes a housing 110 and a connecting block 120, the housing 110 The top is provided with a top plate 111, the surface of the top plate 111 is provided with a groove 112, the connecting block 120 is arranged on one side of the housing 110, a sliding cavity is opened in the connecting block 120, and a baffle plate 121 is slidably connected in the sliding cavity. The side wall of the baffle plate 121 is provided with a plurality of slots 122, the two sides of the connection block 120 are provided with a through groove 123 communicating with the sliding cavity, and a push block 124 is slidably connected in the through groove 123, and the push block 124 is close to the baffle plate 121 One end of the connecting block 120 is inclined, and...

Embodiment 2

[0059] In order to improve the speed of lifting the baffle plate 121, the machine is improved as follows on the basis of Embodiment 1:

[0060] see Figure 10-Figure 11 As shown, wherein, the bottom of the groove 112 is provided with a box body 240, the inner wall of the box body 240 is slidably connected with a pressure plate 241, the top of the pressure plate 241 is connected with the bottom of the connecting platform 219, and the bottom of the box body 240 is connected with a connecting pipe 242, and the connecting pipe 242 passes through the top plate 111 and is connected with a cylinder barrel 243. The cylinder barrel 243 is arranged in the connection block 120. The cylinder barrel 243 is slidably connected with a cylinder column 244. The top of the cylinder column 244 is connected with the bottom of the baffle plate 121. When the connecting platform 219 When moving down, the connection table 219 drives the pressure plate 241 to move down, at this time, the gas in the box...

Embodiment 3

[0062] In order to realize the automatic control of driven table 231, on the basis of embodiment 1, the machine is improved as follows:

[0063] see Figure 12 As shown, wherein, the lifting device 200 also includes an induction system, an induction system controller, the controller is connected to the electric push rod 230, the output end of the controller is connected to a distance measuring sensor, and the distance measuring sensor is installed on the side wall of the box body 211, The output end of the ranging sensor is connected to an analysis module, and the output end of the analyzing module is connected to the controller. When the front of the vehicle moves to the box 211, the ranging sensor measures the distance to the vehicle, and then sends the measured data to the analysis unit. In the module, the analysis module analyzes the data, and when the data value is greater than the preset value, the analysis module sends a voltage signal to the controller. The controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com