Method for treating sulfate pulping black liquor by using black liquor coal water slurry prepared from dilute black liquor

A treatment method and technology for pulping black liquor, which are applied in the regeneration of pulping liquid, regeneration of alkali liquor, and fiber raw material treatment, etc. The effect of reducing costs and eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

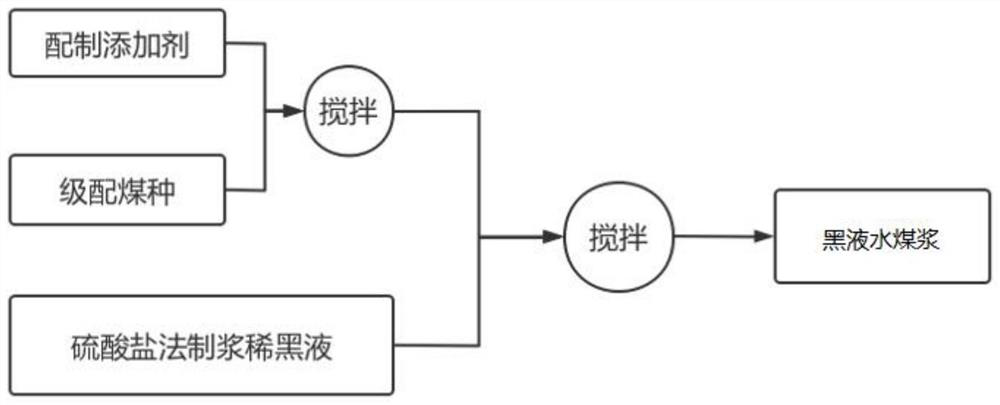

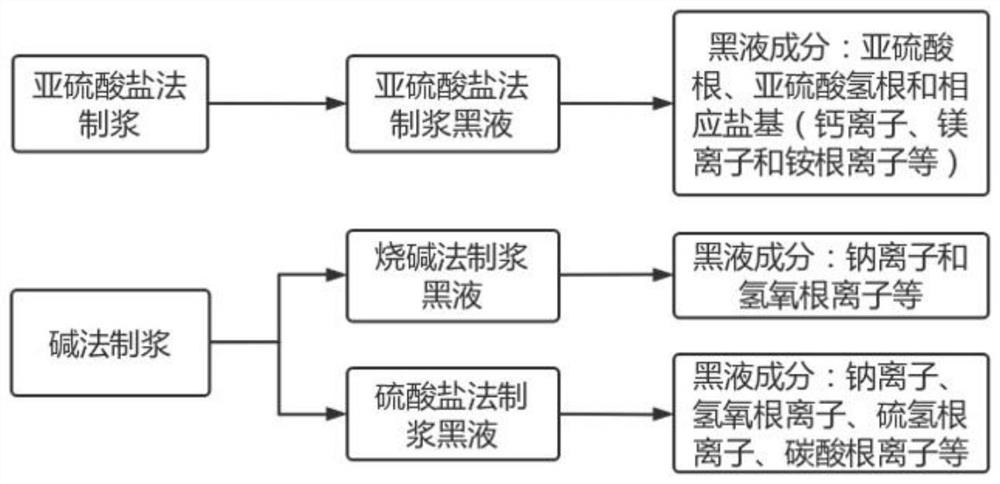

Method used

Image

Examples

Embodiment 1

[0027] Preparation of coal powder: Take raw coal with a calorific value of 24.03MJ / kg, an ash content of 15%, and a volatile content of 40%, and pulverize it with a ball mill, and sieve the pulverized coal powder through a 40-mesh sieve to obtain coal pink.

[0028] Preparation of additives: the stabilizer is sodium carboxymethyl cellulose, the dispersant is sodium polynaphthalene sulfonate, add sodium carboxymethyl cellulose: sodium polynaphthalene sulfonate at a ratio of 2:3, and then fully stir.

[0029] Add additives to coal powder: Add additives according to 1% of the mass of coal powder, stir while adding, so that coal powder and additives are fully mixed.

[0030] Mix the pulverized coal with additives and black liquor: Add the pulverized coal with additives to the black liquor for stirring, the solid content of the black liquor is: 10%, the pulverized coal with additives: the mixing ratio of black liquor: 1 :0.6.

[0031] Combustion: The prepared black liquor coal-wa...

Embodiment 2

[0033] Preparation of coal powder: Take raw coal with a calorific value of 26.67MJ / Kg, an ash content of 8.25%, and a volatile content of 27.68%, and pulverize it with a ball mill, and sieve the pulverized coal powder through a 40-mesh sieve to obtain coal pink.

[0034] Preparation of additives: the stabilizer is sodium carboxymethyl cellulose, the dispersant is sodium polynaphthalene sulfonate, add sodium carboxymethyl cellulose: sodium polynaphthalene sulfonate at a ratio of 2:3, and then fully stir.

[0035] Add additives to coal powder: Add additives according to 1% of the mass of coal powder, stir while adding, so that coal powder and additives are fully mixed.

[0036] Mix the pulverized coal with additives and black liquor: Add the pulverized coal with additives to the black liquor for stirring, the solid content of the black liquor is: 12%, the pulverized coal with additives: the mixing ratio of black liquor: 1 :1.2.

[0037] Combustion: The prepared black liquor co...

Embodiment 3

[0039] Preparation of coal powder: Take raw coal with a calorific value of 35MJ / Kg, an ash content of 7%, and a volatile content of 10%, and pulverize it with a ball mill, and sieve the pulverized coal powder through a 40-mesh sieve to obtain coal powder .

[0040] Preparation of additives: the stabilizer is sodium carboxymethyl cellulose, the dispersant is sodium polynaphthalene sulfonate, add sodium carboxymethyl cellulose: sodium polynaphthalene sulfonate at a ratio of 2:3, and then fully stir.

[0041] Add additives to coal powder: Add additives according to 1% of the mass of coal powder, stir while adding, so that coal powder and additives are fully mixed.

[0042] Mix the pulverized coal with additives and black liquor: Add the pulverized coal with additives to the black liquor for stirring, the solid content of the black liquor is: 20%, the pulverized coal with additives: the mixing ratio of black liquor: 1 :1.7.

[0043] Combustion: The prepared black liquor coal-water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com