Conveyor belt longitudinal tearing detection method and device based on machine vision

A technology of longitudinal tearing and machine vision, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problem of inability to accurately calculate the longitudinal tear width and longitudinal tear length of the conveyor belt surface, and the inability to accurately calculate Problems such as the appearance size of the conveyor belt and the low detection rate of longitudinal tearing on the surface of the conveyor belt have been solved, and the effect of obvious and intuitive presentation, simple image processing process and high detection rate has been achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

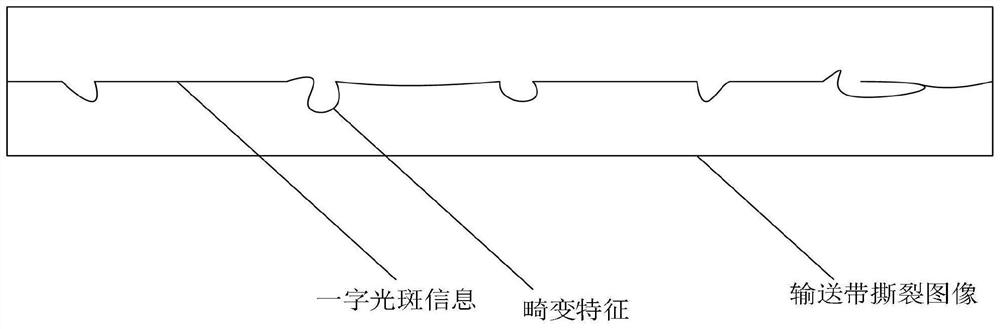

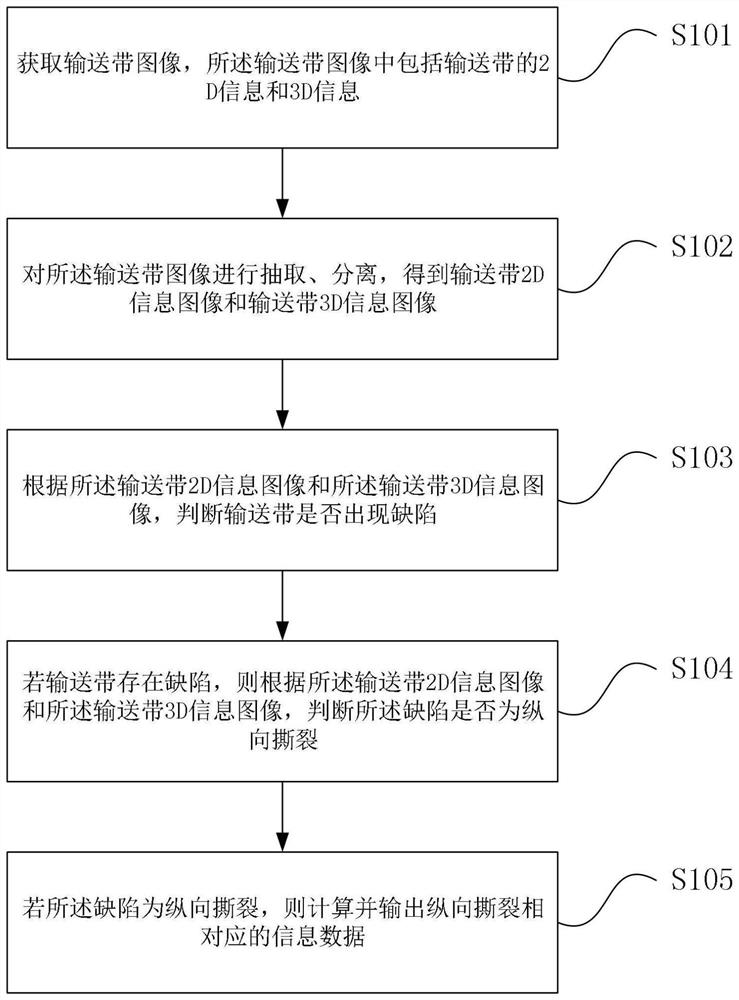

[0074] see figure 2 , the application provides a machine vision-based conveyor belt longitudinal tear detection method, including:

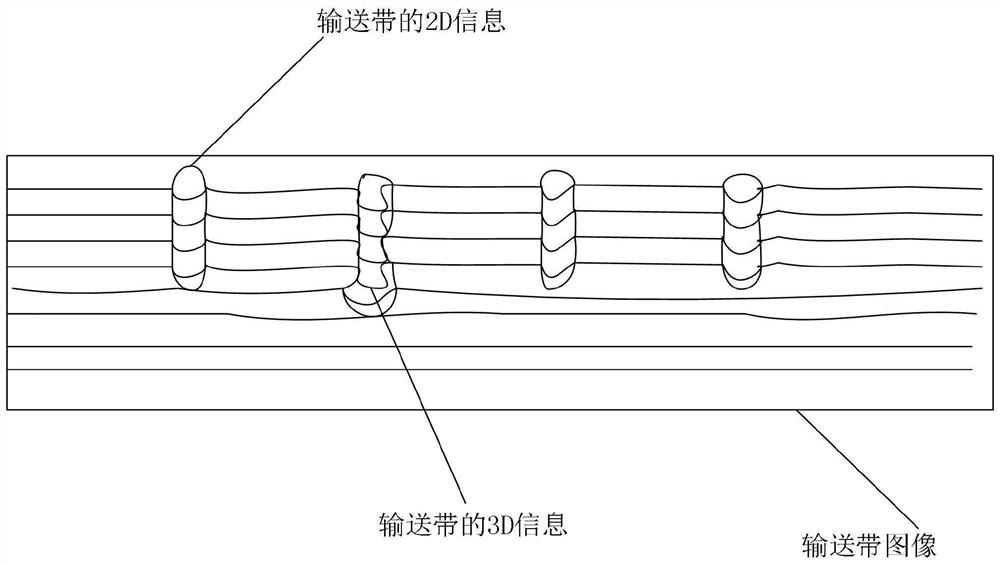

[0075] S101. Acquire a conveyor belt image, the conveyor belt image includes 2D information and 3D information of the conveyor belt; wherein, the conveyor belt image is an image collected by the acquisition device when the surface light source and the multi-line laser source are turned on at the same time, and the acquired The schematic diagram of the conveyor belt image is as follows image 3 As shown, after the acquisition device collects the image of the conveyor belt, the image sensor of the acquisition device transmits the image of the conveyor belt to the PC.

[0076] Further, in step S101 of Embodiment 1, both the wavelength band of the surface light source and the wavelength band of the multi-line laser source are in the sensitive spectrum range of the acquisition device, and the wavelength band of the surface light source and the The ...

Embodiment 2

[0093] Corresponding to the foregoing embodiment 1 of a method for detecting longitudinal tearing of a conveyor belt based on machine vision, the present application also provides an embodiment of a device for detecting longitudinal tearing of a conveyor belt based on machine vision. Such as Figure 7 As shown, the device includes:

[0094] Acquisition equipment, surface light source equipment, multi-line lasers, signal control equipment ( Figure 7 not shown) and PC ( Figure 7 Not shown in), the collection equipment, surface light source equipment, multi-line laser and signal control equipment are all arranged under the conveyor belt, and are all connected to the PC by communication;

[0095] The collection device is used to collect images of the conveyor belt when the surface light source and the multi-line laser source are on;

[0096] The surface light source device is used to project a surface light source to the conveyor belt, and the surface light source is Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com