Oiling equipment for hardware fittings

A technology for applying oil and accessories, applied in the field of hardware processing, can solve the problems of low processing efficiency, falling sundries, time-consuming and laborious, etc., and achieve the effect of evenly applying oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

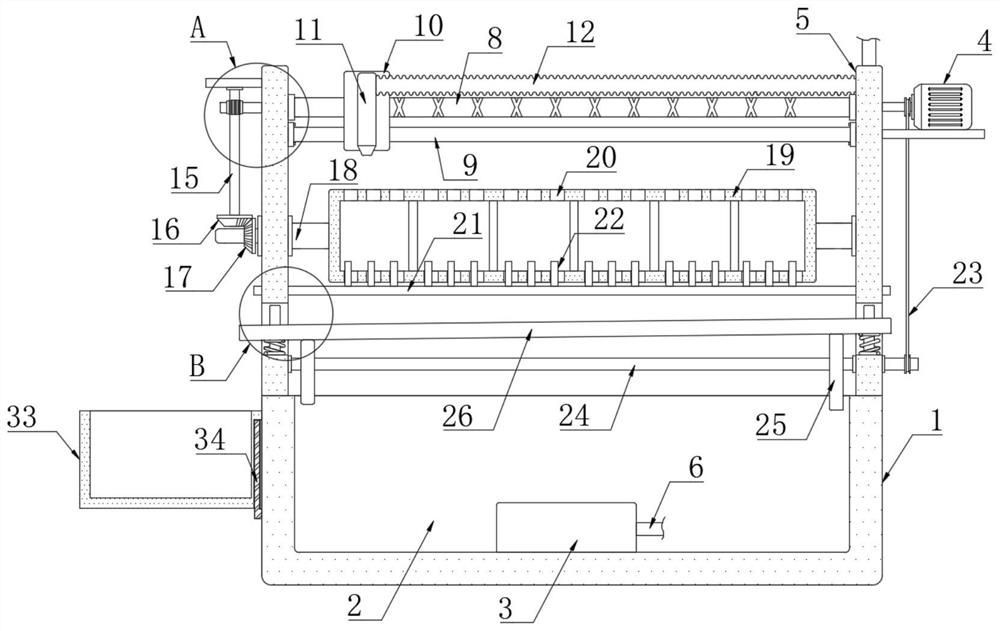

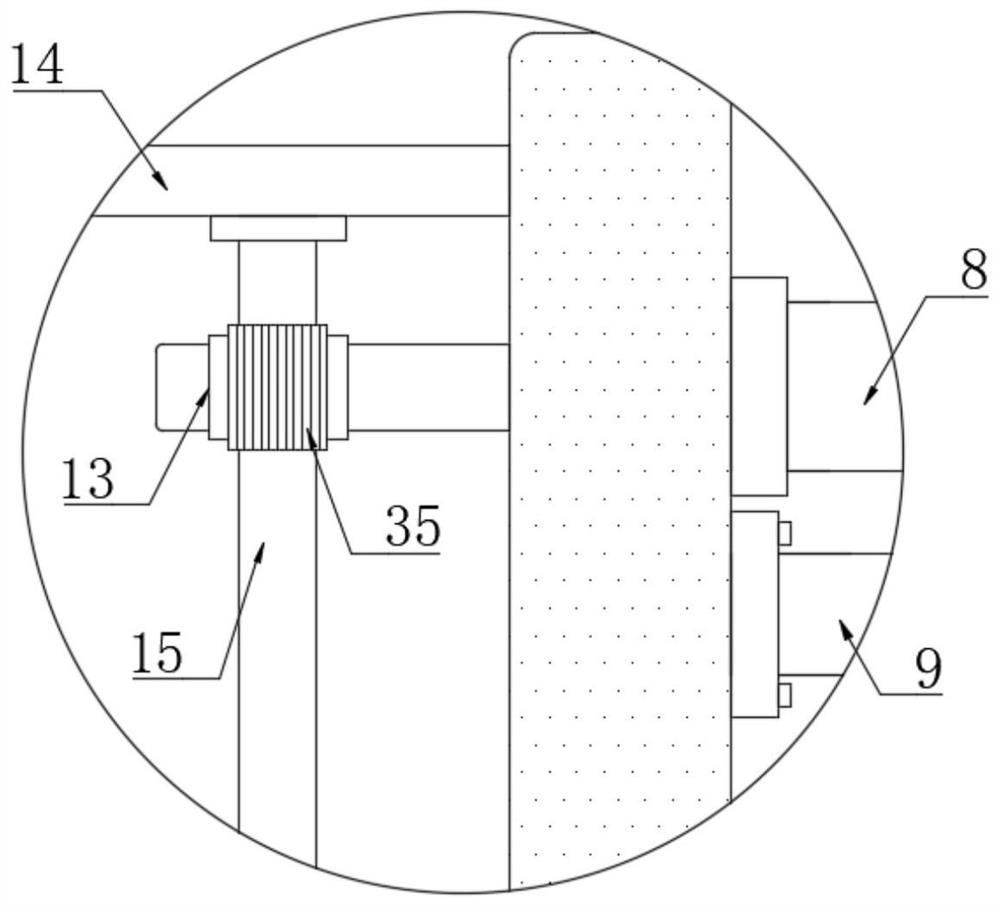

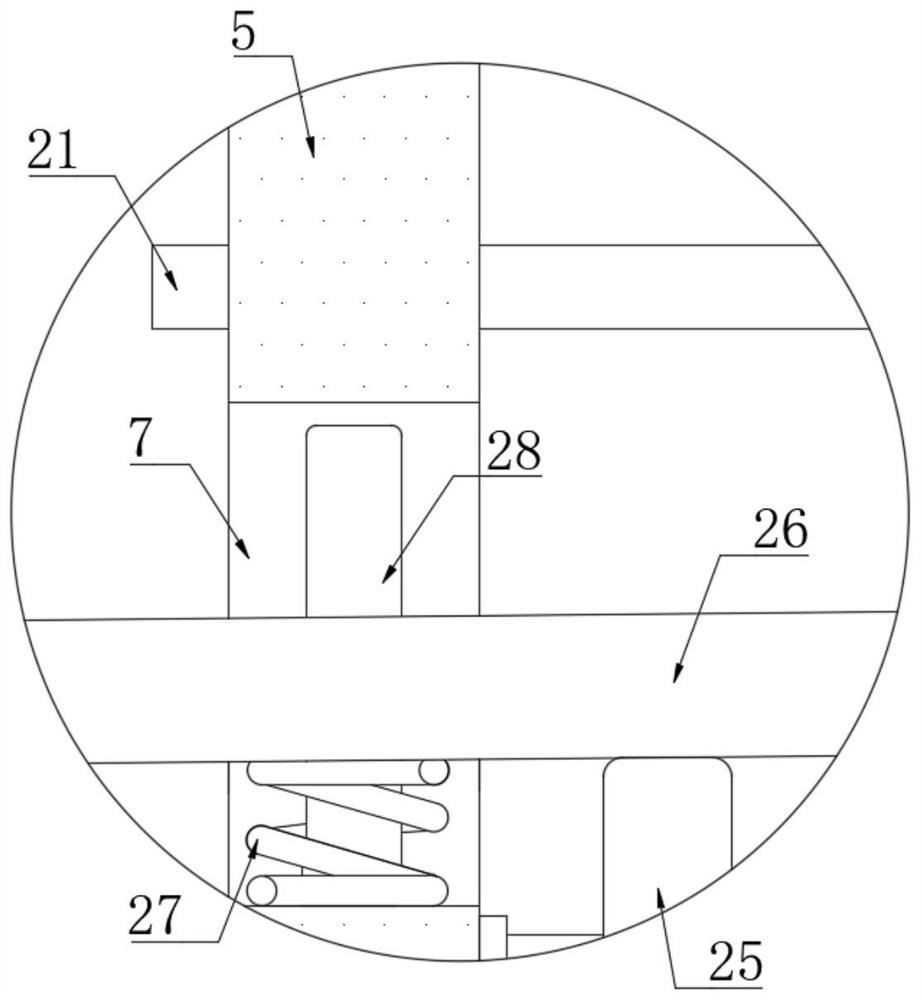

[0031] refer to Figure 1-6 , a kind of oiling equipment for hardware fittings, comprising a shell 1, the upper end of the shell 1 is provided with a placement tank 2, the oil required for processing is stored in the placement tank 2, and a liquid pump 3 is installed at the bottom of the placement tank 2, The liquid outlet of the liquid pump 3 is equipped with a connecting pipe 6, and the upper end of the housing 1 is symmetrically and fixedly connected with two mounting plates 5, and a reciprocating screw rod 8 is rotatably connected between the two mounting plates 5, and between the two mounting plates 5 The first guide rod 9 is fixedly connected, the reciprocating screw rod 8 is threadedly connected with the moving block 10, the first guide rod 9 runs through the moving block 10, the moving block 10 is equipped with a nozzle 11, and the nozzle of the nozzle 11 adopts an atomizing nozzle. The right side of 11 is equipped with a bellows 12, the right end of the bellows 12 is ...

Embodiment 2

[0042] refer to Figure 7-10 , the difference between this embodiment and Embodiment 1 is that: the two ends of the strip plate 21 pass through the corresponding mounting plate 5, the strip plate 21 is fixedly connected with a connecting block 29, and the connecting block 29 connects with the second spring 30 The side wall of the mounting plate 5 on the left side is elastically connected, a push rod 31 is installed on the first rotating rod 18 on the right side, and an inclined-plane block 32 is fixedly connected on the strip plate 21, and the push rod 31 cooperates with the inclined-plane block 32 , the push rod 31 can push the inclined block 32 to move to the right, and then drive the strip plate 21 to move to the right.

[0043] Compared with Embodiment 1, in this embodiment, when the first rotating rod 18 drives the rotating cylinder 19 to rotate, it further drives the push rod 31 to rotate. When the push rod 31 contacts the inclined block 32 and continues to rotate, it ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com