Spraying equipment for building material

A technology for spraying equipment and building materials, which can be used in spraying devices, liquid spraying devices, etc., and can solve problems such as single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

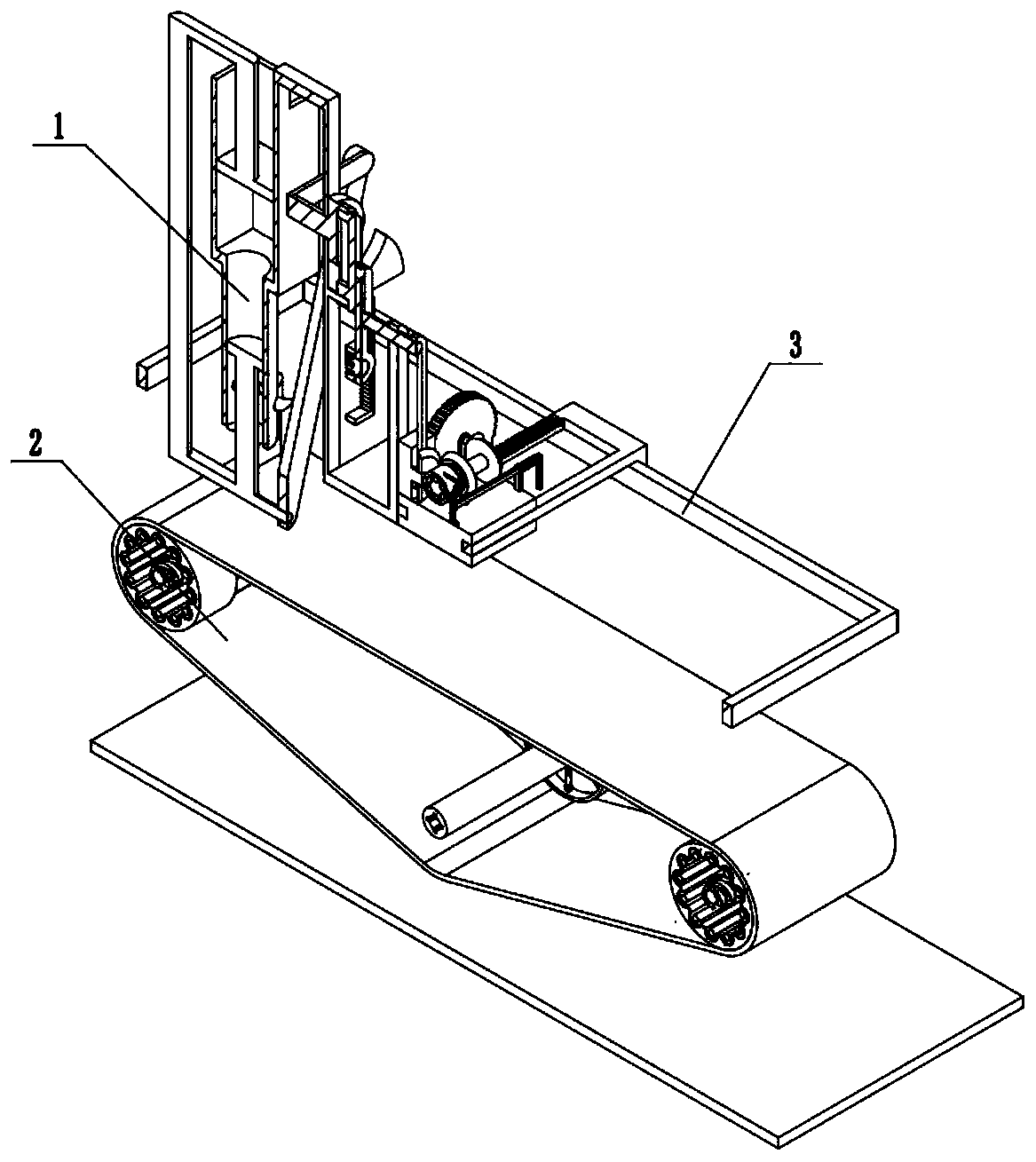

[0030] Combine below Figure 1-14 Describe this embodiment, a spraying equipment for building materials, including a spraying assembly 1, a carrying assembly 2, and a driving assembly 3, characterized in that: the spraying assembly 1 is connected to the driving assembly 3, and the carrying assembly 2 is connected with the drive assembly 3.

specific Embodiment approach 2

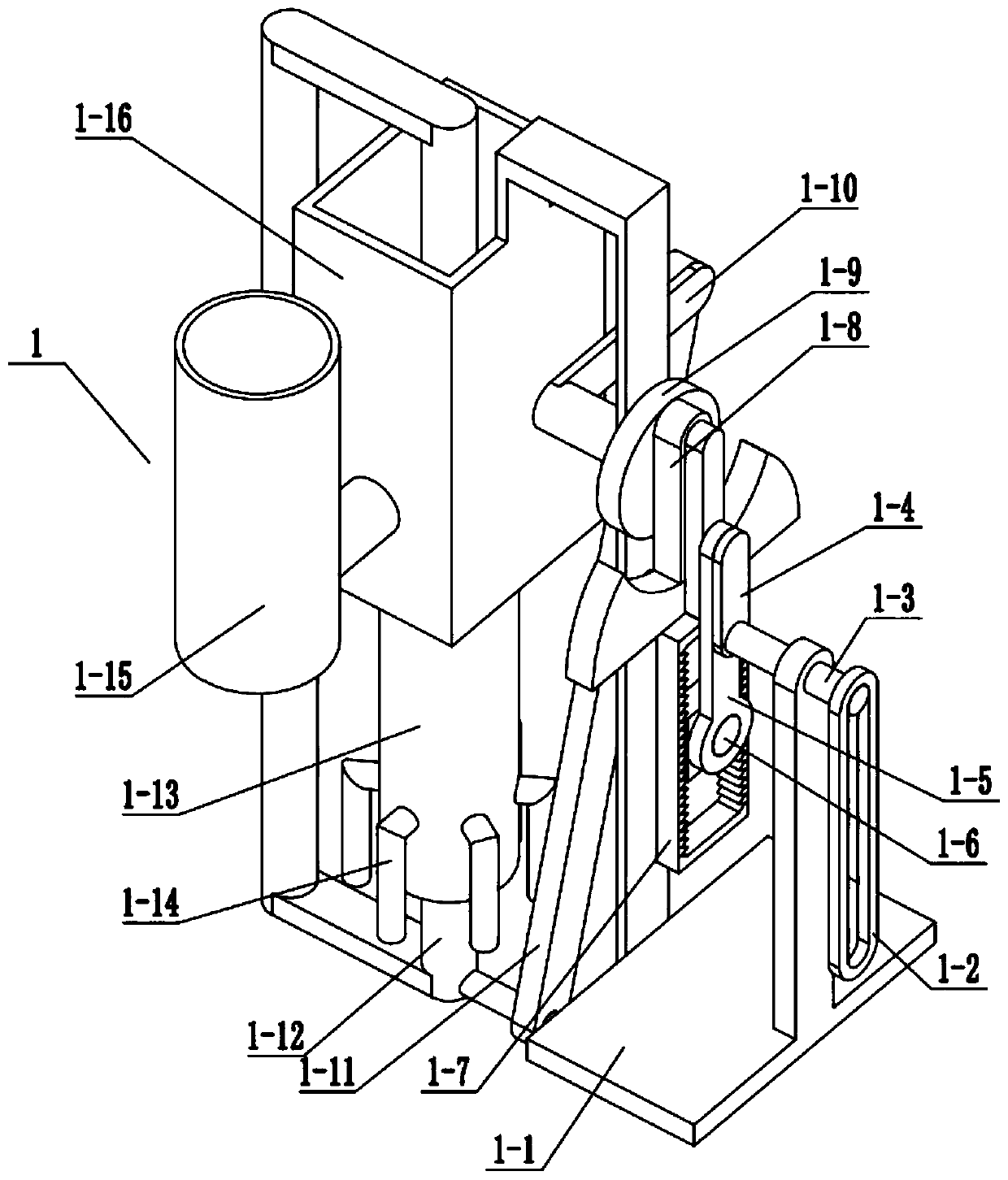

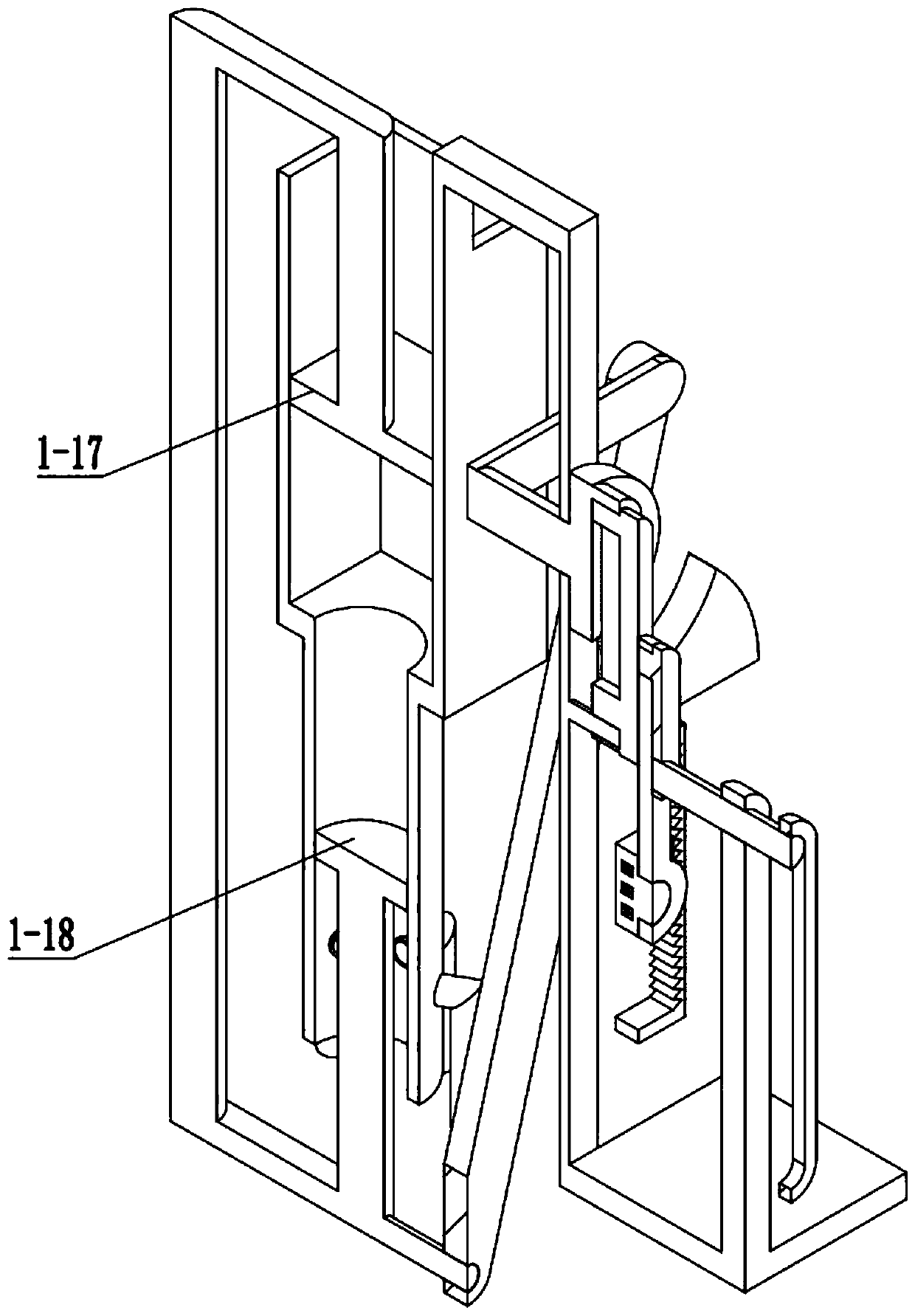

[0032] Combine below Figure 1-14 Describe this embodiment, this embodiment will further explain Embodiment 1, the spray assembly 1 includes a fixed bottom plate 1-1, a belt 1-2, a middle end rotating column 1-3, an eccentric rod 1-4, an eccentric Rod hinge rod 1-5, rectangular slider 1-6, swing rod 1-7, U-shaped rod 1-8, runner 1-9, eccentric rod 2 1-10, eccentric rod connecting rod 1-11, Piston rod 1-12, liquid spray sleeve 1-13, spray pipe 1-14, containing pipe 1-15, rectangular sleeve 1-16, upper piston 1-17, lower piston 1-18, inner end slot 1 1-19, the inner end clamping rod one 1-20, the inner end clamping rod push spring one 1-21, the middle end rotating column 1-3 is rotationally connected with the fixed bottom plate 1-1, the belt one 1-2 is connected with the middle end rotating column 1-3 are matingly connected, the eccentric rod 1-4 is fixedly connected with the middle end rotating column 1-3, the eccentric rod 1-4 is rotationally connected with the eccentric rod ...

specific Embodiment approach 3

[0034] Combine below Figure 1-14 Describe this embodiment, this embodiment will further explain the first embodiment, the bearing assembly 2 includes a bearing frame 2-1, a bearing bracket 2-2, a bearing belt 2-3, a connecting belt 2-4, a roller 2 -5, inner end screw rod 2-6, inner end sliding post 2-7, inner end sliding post push spring 2-8, roller two 2-9, inner end spiral groove rod 2-10, spiral groove 2-11, Matching sliding column 2-12, inner casing one 2-13, buffer sliding rod one 2-14, buffer sliding rod two 2-15, buffer spring one 2-16, buffer spring two 2-17, inner end casing Two 2-18, inner casing three 2-19, rectangular slider 2-20, rectangular slider slider 2-21, rectangular slider push spring 2-22, bearing bracket 2-2 and bearing outer frame 2- 1 fixed connection, the first roller 2-5 is rotationally connected with the bearing bracket 2-2, the bearing belt 2-3 is connected with the first roller 2-5, and the belt 2-4 is connected with the first roller 2-5, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com