Sulfide preparation device and method and application of device

A technology for preparing devices and sulfides, applied in chemical instruments and methods, alkali metal sulfides/polysulfides, chemical/physical/physicochemical stationary reactors, etc. Lithium sulfide preparation, complex reaction process and other problems, to achieve the effect of easy separation, high production efficiency and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

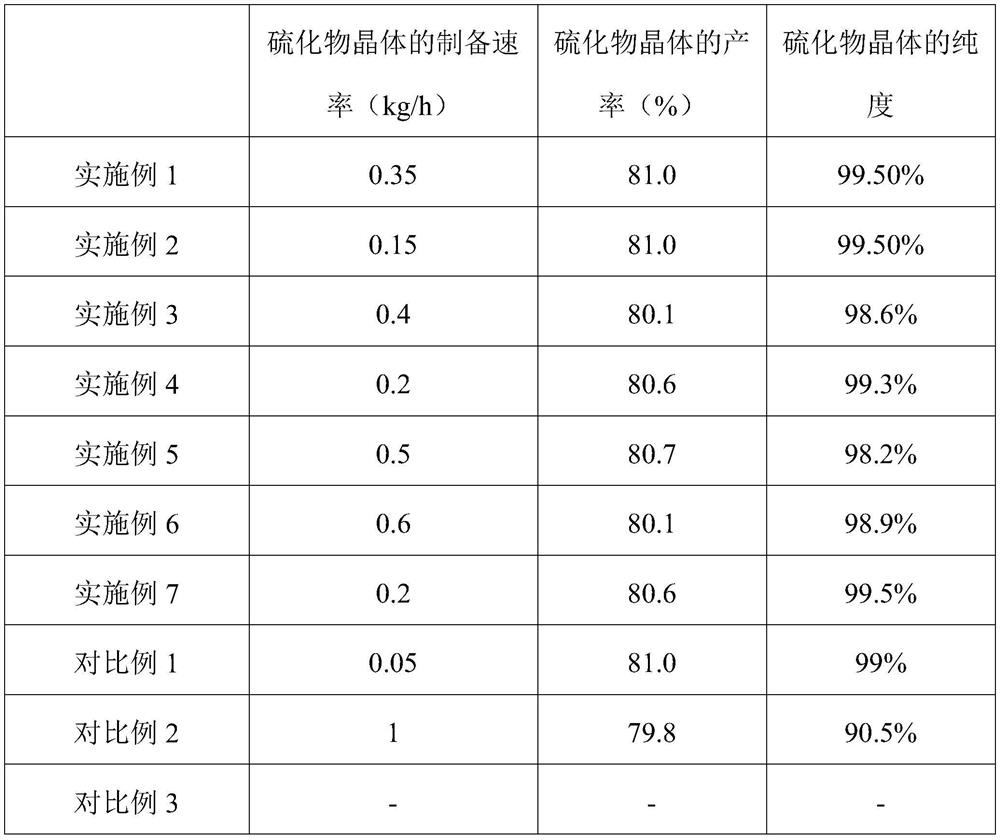

Examples

Embodiment 1

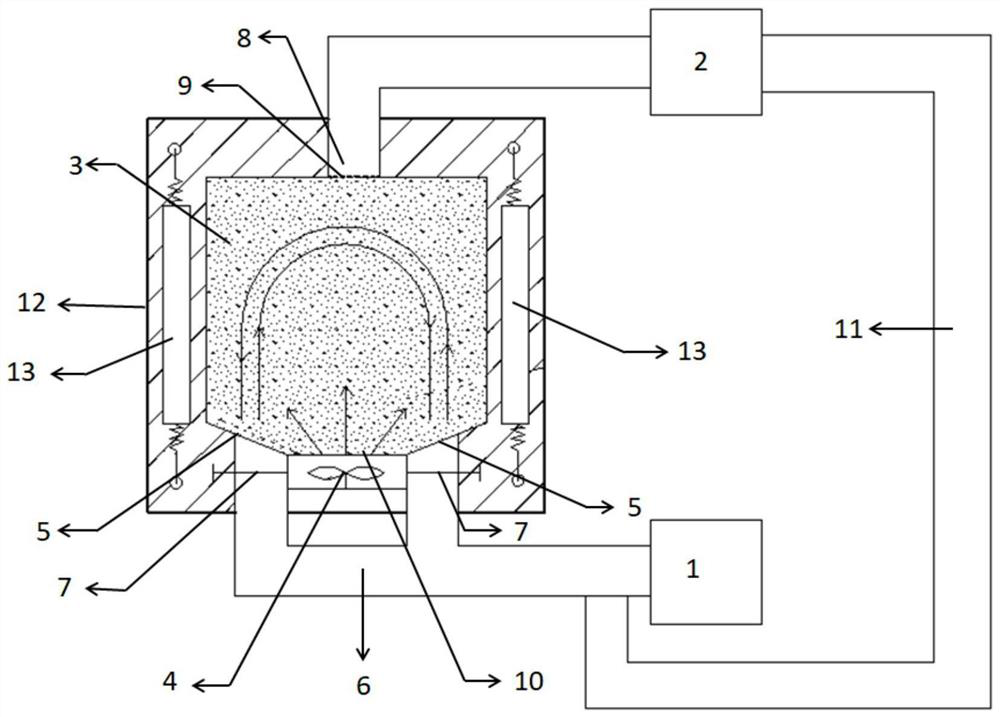

[0032] This embodiment provides a specific implementation method for preparing sulfide by a sulfide preparation device.

[0033] First, 0.5kg of powdered lithium hydroxide is added into the reaction chamber 3, and then 0.6m / s hydrogen sulfide gas is continuously injected into the chamber with a volume of 25.12m under high pressure. 3The inside of the reaction chamber 3 is filled with hydrogen sulfide gas. The automatic control valve 7 can be set with different opening and closing modes according to the needs, and the opening and closing of the hydrogen sulfide inlet 5 under the reaction chamber is opened and closed in sequence. When the automatic control valve 7 on the left is opened and the automatic control valve 7 on the right is closed, the hydrogen sulfide gas is completely charged into the reaction chamber 3 from the left air inlet at a relatively high pressure. The powdery lithium hydroxide inside the body is blown up from the left side by the hydrogen sulfide gas and ...

Embodiment 2

[0036] In this embodiment, the flow rate of hydrogen sulfide is replaced by 0.1 m / s, and other conditions are the same as in embodiment 1.

Embodiment 3

[0038] In this embodiment, the flow rate of hydrogen sulfide is replaced by 1m / s, and other conditions are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com