Isobaric liquid injection device of automobile lithium battery liquid injection machine

A lithium battery liquid injection and liquid injection device technology, which is applied to battery pack components, circuits, electrical components, etc., can solve problems such as easy generation of air bubbles and limit the development of electrolyte injection efficiency, so as to reduce the number of air bubbles and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

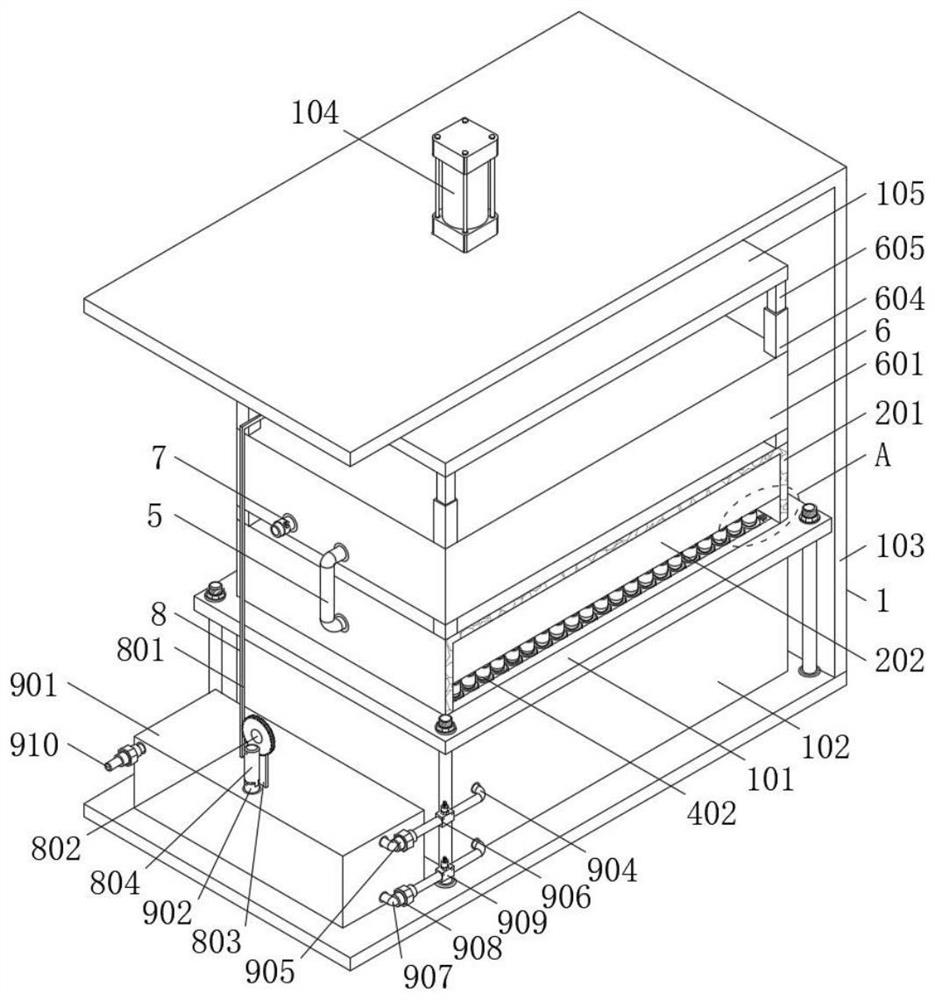

[0051] The specific embodiment is: the second piston seat 903 is used to supplement the pressure in the inner storage box 102 , so that the pressure inside and outside the battery case 10 is changed synchronously, effectively ensuring the stability of the battery case 10 .

[0052] Specifically, such as Figure 4 As shown, the pressure regulating assembly 9 includes a piston barrel 901, the bottom of the piston barrel 901 is fixedly connected to the top of the outer frame body 101, the second piston seat 903 is sleeved in the piston barrel 901, and the top of the second piston seat 903 is fixedly connected with a second piston seat 903. Two piston rods 902, the second piston rod 902 is slidingly connected to the top of the piston cylinder 901, the top of the second piston rod 902 is hinged with the bottom end of the rotating shaft 804 through a pin shaft, the front side end surface of the piston cylinder 901 and the inner storage box 102 and the second connecting pipe 907 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com