Perovskite thin film and preparation method thereof, perovskite solar cell, optoelectronic device

A solar cell and perovskite technology, applied in the direction of electrical solid devices, electrical components, semiconductor devices, etc., can solve the problems of poor film forming quality and low performance, achieve high crystallinity, and promote the effect of nucleation and growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

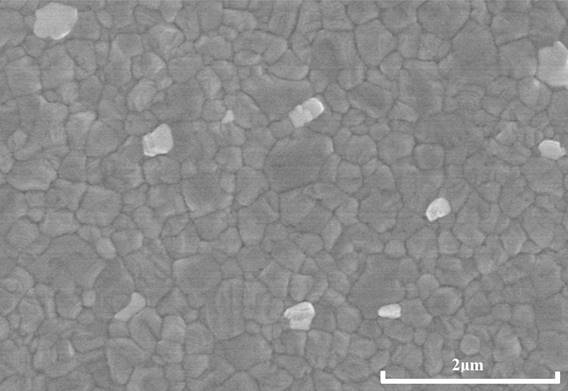

Embodiment 1

[0050] Embodiment 1 is the preparation steps of the perovskite film and its corresponding perovskite solar cell.

[0051] The preparation of perovskite thin films includes the following steps:

[0052] (1) Weigh 39mg CsI (cesium iodide), 146.17mg FAI (ForMaMidiniuM Iodide, formamidine hydroiodide), 357.28mg PbI 2 (lead iodide), 82.58mg PbBr 2 (lead bromide) and 20.4 mg MACl (methylammonium chloride) and dissolved in 1 mL of DMF (N,N-dimethylformamide) for the configuration of 1.0 mmol / mL of Cs 0.15 FA 0.85 PB 2.55 Br 0.45 Perovskite precursor liquid, the prepared perovskite precursor liquid is slit-coated to form a perovskite precursor liquid film on the substrate.

[0053] (2) At room temperature (25°C), 0.2MPa high-purity nitrogen gas is bubbled into the toluene solvent to form a mixed gas (or aerosol) of high-pressure nitrogen carrying toluene solvent molecules, and enters the air knife to form an air curtain. The angle between the outlet direction of the air knife an...

Embodiment 2

[0068] Embodiment 2 is the preparation steps of the perovskite film and its corresponding perovskite solar cell.

[0069] The difference between Example 2 and Example 1 is that the method of forming a mixed gas in the preparation step (2) of the perovskite thin film and the preparation step (4) of the perovskite solar cell in Example 2 is 0.2MPa high-purity nitrogen and 0.1 The MPa toluene solvent vapor is mixed and formed through the three-way valve. All the other processes are the same as in Example 1.

[0070] The preparation of perovskite thin films includes the following steps:

[0071] (1) Weigh 39mg CsI (cesium iodide), 146.17mg FAI (ForMaMidiniuM Iodide, formamidine hydroiodide), 357.28mg PbI 2 (lead iodide), 82.58mg PbBr 2 (lead bromide) and 20.4 mg MACl (methylammonium chloride) and dissolved in 1 mL of DMF (N,N-dimethylformamide) for the configuration of 1.0 mmol / mL of Cs 0.15 FA 0.85 PB 2.55 Br 0.45 Perovskite precursor liquid, the prepared perovskite precur...

Embodiment 3

[0086] Embodiment 3 is the preparation steps of the perovskite film and its corresponding perovskite solar cell.

[0087] The difference between Example 3 and Example 2 is that the vapor temperature of the 0.1MPa toluene solvent before mixing in the preparation step (2) of the perovskite thin film in Example 3 and the preparation step (4) of the perovskite solar cell is 110°C, And the temperature of the mixed gas at the air outlet of the air knife is 60°C. All the other processes are the same as in Example 2.

[0088] The preparation of perovskite thin films includes the following steps:

[0089] (1) Weigh 39mg CsI (cesium iodide), 146.17mg FAI (ForMaMidiniuM Iodide, formamidine hydroiodide), 357.28mg PbI 2 (lead iodide), 82.58mg PbBr 2 (lead bromide) and 20.4 mg MACl (methylammonium chloride) and dissolved in 1 mL of DMF (N,N-dimethylformamide) for the configuration of 1.0 mmol / mL of Cs 0.15 FA 0.85 PB 2.55 Br 0.45 Perovskite precursor liquid, the prepared perovskite p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com